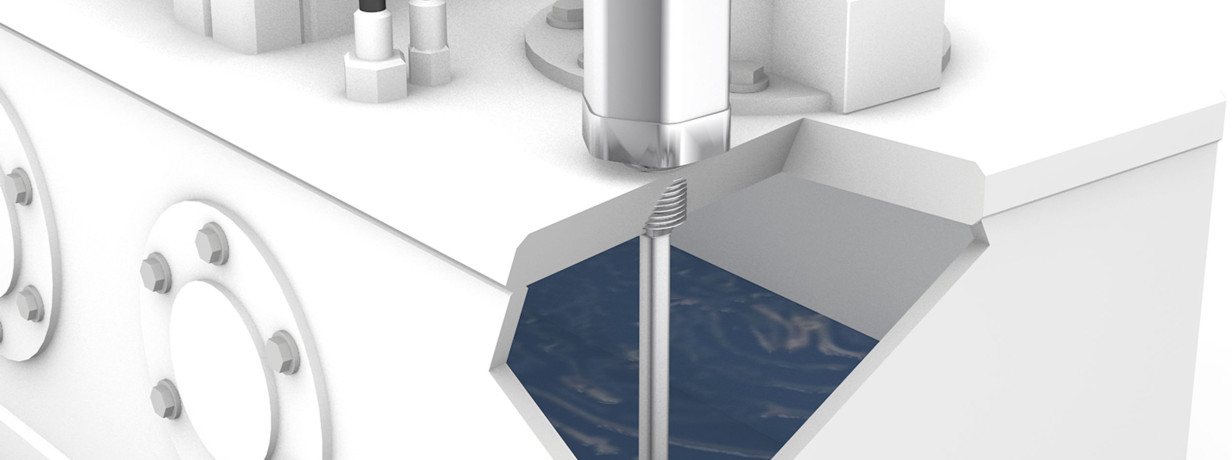

Monitoring levels on the hydraulic power unit

To reliably detect the hydraulic fluid fill level, you just need magnetostrictive fill level sensors with floats. These are fully encapsulated for ruggedness. They stand out with their precision and are designed for high sampling rates.

Both analog signals (0...10 V or 4...20 mA) and IO-Link can be used as interfaces.

The features

- Made of corrosion-proof stainless steel with high surface quality

- Continuous precise measurement in the μm range for highly accurate results

Downloads

-

Industry brochure metalworking

Products

Products