- Dimension

- 35 x 35 x 31 mm

- Style Housing

- block style

- Connection

- Cable with connector, M12x1-Male, 3-pin, 0.15 m, PUR

- Cable shield

- yes

- Housing material

- PA

- Measuring range

- 0...17 mm

- Analog output

- Analog, voltage 0...10 V

- Output characteristic

- Adjustable

- Repeat accuracy

- ±50 µm

- Non-linearity max.

- ±250 µm

- Operating voltage Ub

- 15...30 VDC

- Ambient temperature

- -25...70 °C

- IP rating

- IP67

- Approval/Conformity

-

CE

UKCA

cURus

WEEE

-

Datasheet

-

MTTF Certificate

-

Disposal

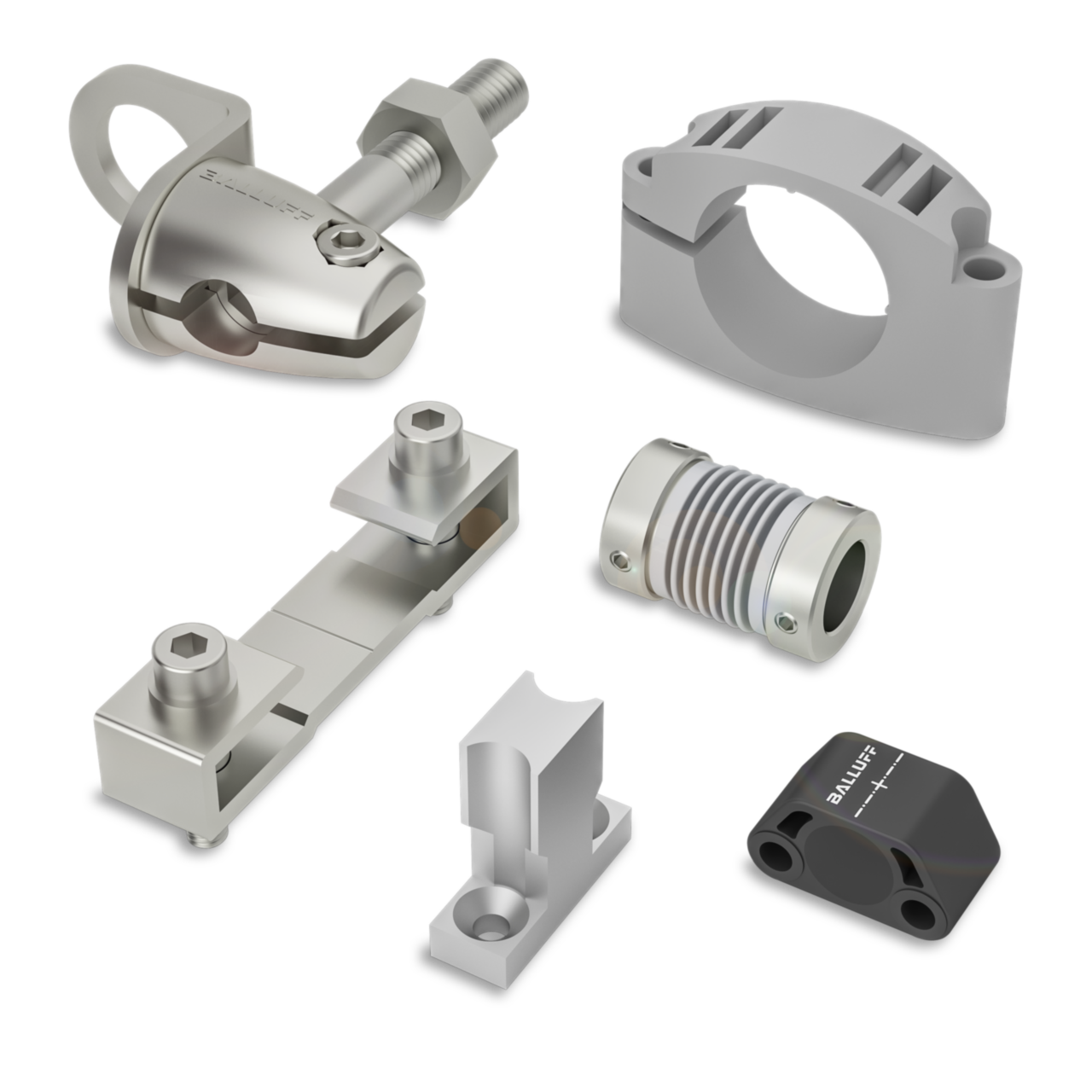

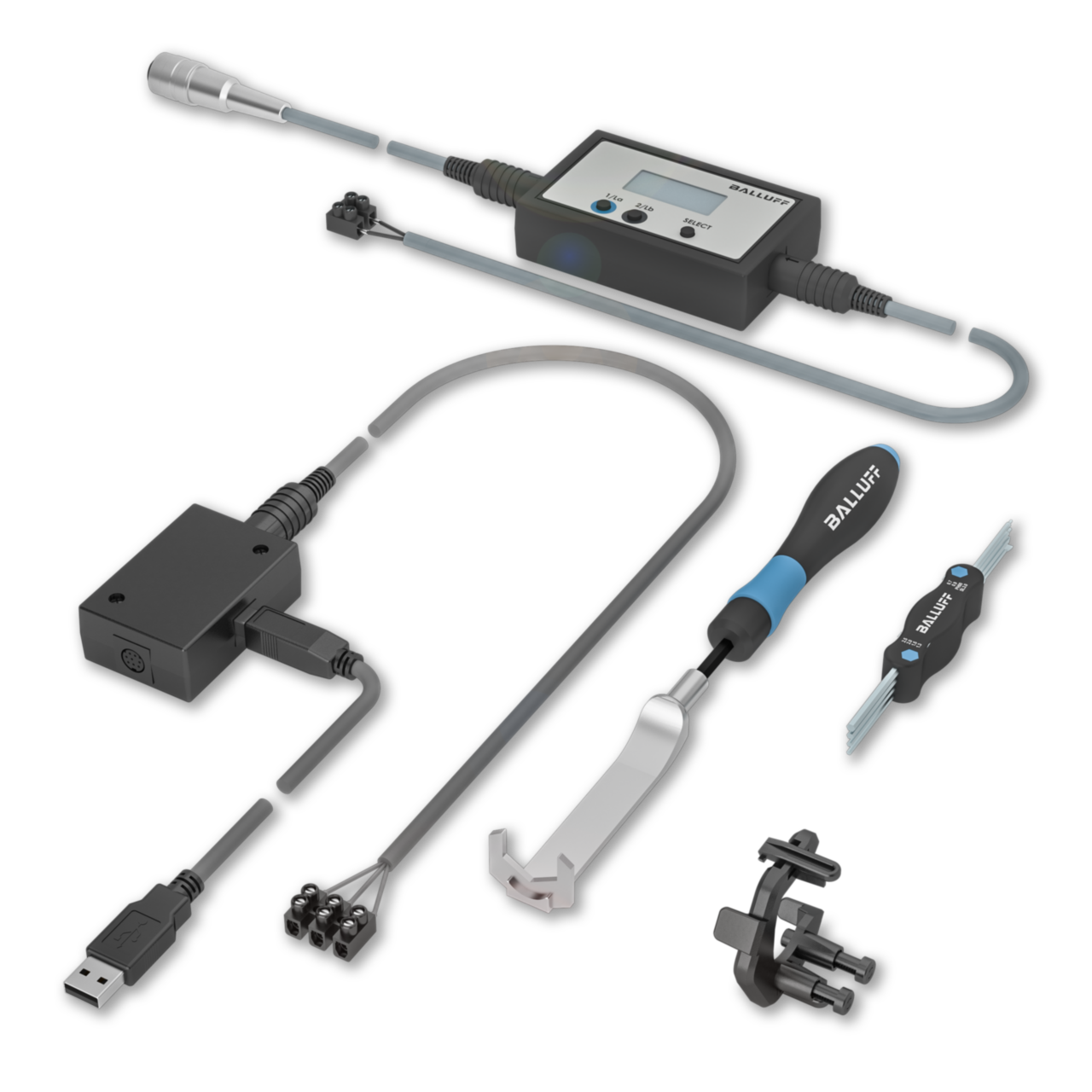

Mandatory accessories

- ECLASS 10.1

- 27-27-07-02

- ECLASS 11.0

- 27-27-07-02

- ECLASS 4.1

- 27-27-07-02

- ECLASS 5.1.3

- 27-27-07-02

- ECLASS 5.1.4

- 27-27-07-02

- ECLASS 6.2

- 27-27-07-02

- ECLASS 8.1

- 27-27-07-02

- ECLASS 9.0

- 27-27-07-02

- ECLASS 9.1

- 27-27-07-02

- ETIM 4.0

- EC001818

- ETIM 5.0

- EC001818

- ETIM 6.0

- EC001818

- ETIM 7.0

- EC001818

- UNSPSC 11

- 41111926

- UNSPSC 7.0901

- 41111926

Products

Products