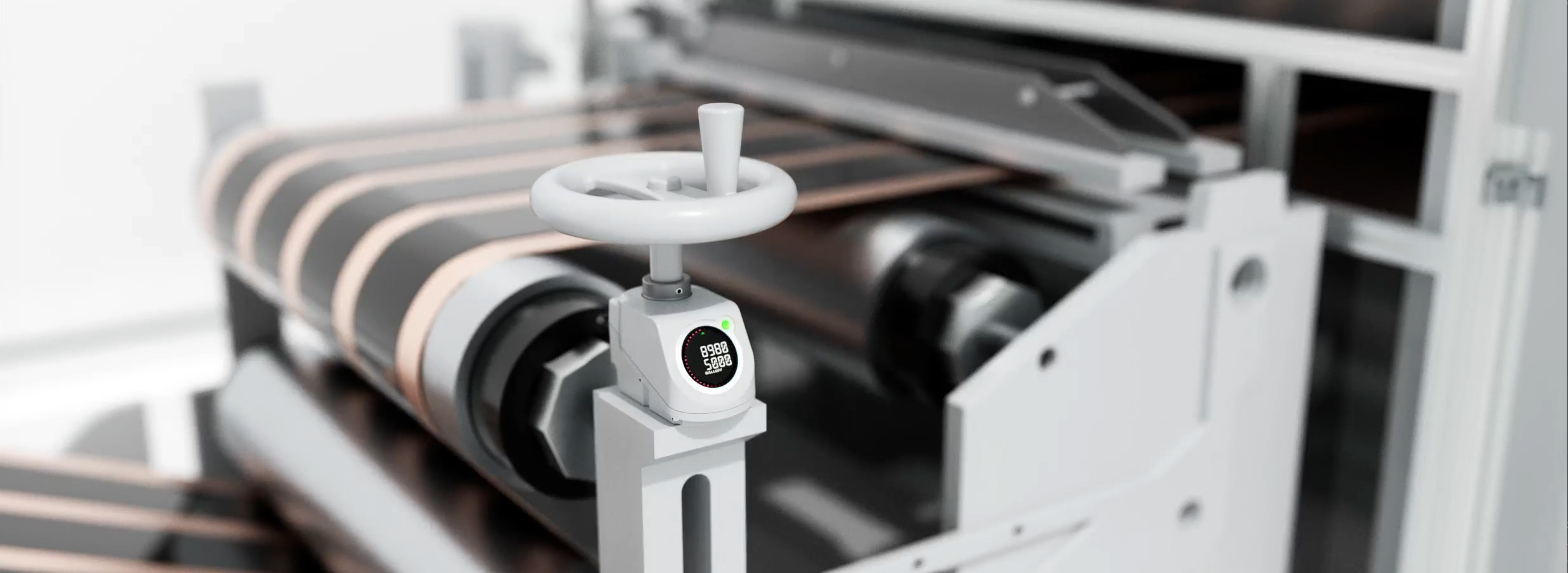

Guided adjustment of the roller position during calendering

BDG digital position indicator for fast and reliable format changes

The BDG digital position indicator with intuitive user interface supports you with semi-automatic format changeovers. It enables the roll position to be set quickly and precisely so that machines can be efficiently adjusted to different batch sizes. The running light guides you when turning the wheel and clearly indicates the target value. In addition, the system offers intelligent functions such as monitoring the internal temperature and relative humidity, which provide additional safety and reliability during operation.

Features

- Advanced IO-Link functionality for easy installation and data processing

- Integrated condition monitoring, including internal temperature and humidity monitoring

- Robust housing with IP69K protection and ECOLAB certification, ideal for demanding industrial environments

Recommended products for efficient format adjustment

RFID read/write heads for change part identification

- Product group

- HF (13.56 MHz)

- Dimension

- Ø 30 x 83 mm

- Installation

- metal-free (clear zone)

- Antenna type

- round

- Supported data carrier types

-

DIN ISO 14443

DIN ISO 15693 - Connection

- Connector, M12x1-Male, 4-pin

- Housing material

- Brass, Nickel-plated brass nuts, nickel-plated

- Ambient temperature

- -20...80 °C

- IP rating

- IP67

- Approval/Conformity

-

CE

UKCA

cULus

FCC

IC (Radio)

WEEE

MIC

KC

NBTC

IMDA

MCMC

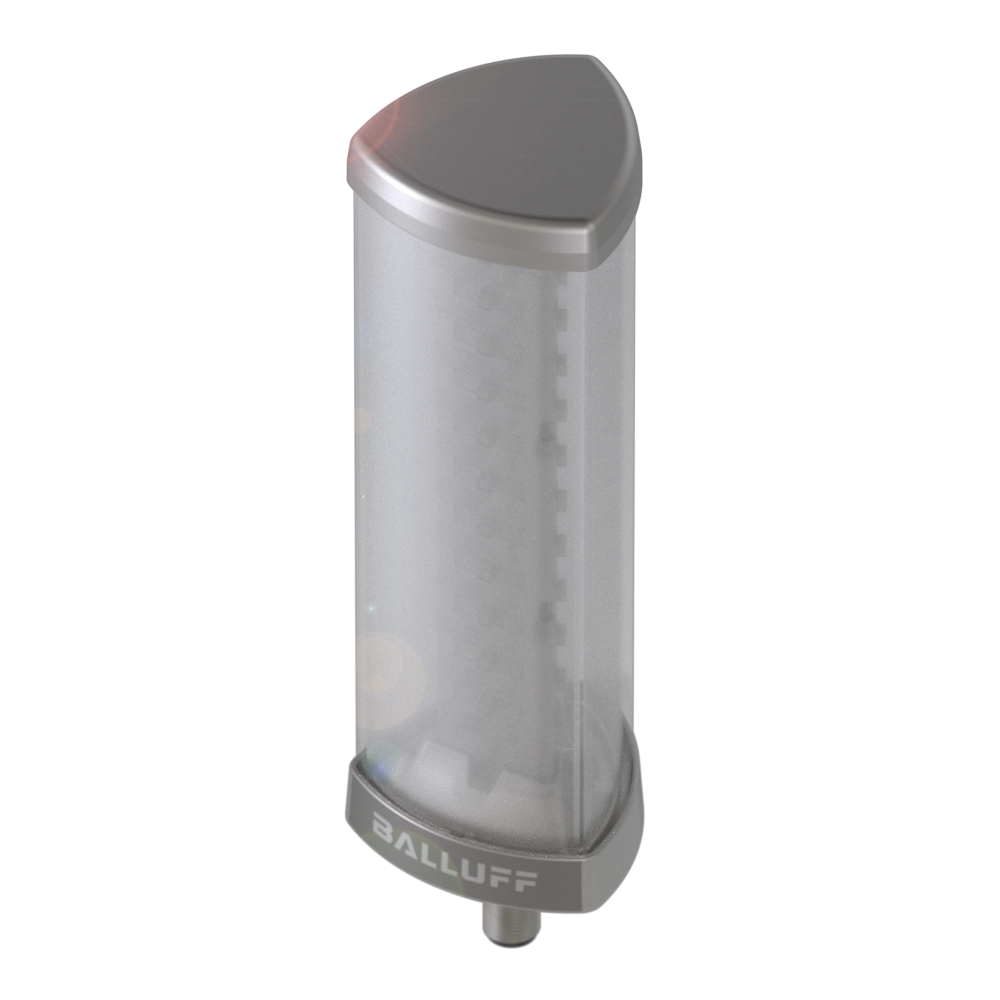

Visualization of the system status

- Principle of operation

- Indicator light

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 3

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Flexi-Mode - Setting

- Function indicator

- Additional function

- Expanded process data

- Dimension

- 60 x 60 x 213 mm

- Housing material

-

PC, Transparent, Cu 15 µm, Ni 15 µm

Die-cast zinc - Mounting part

- Screws M18

- Ambient temperature

- -5...50 °C

- IP rating

- IP65

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 7.2 ms

- Process data IN

- 1 byte

- Process data OUT

- 8 bytes

Digital position indicator with display

- Display

- Digital display

- Shaft type

- Hollow shaft

- Shaft diameter

- 20 mm

- Resolution rotary

- 14000 ppr

- Repeat accuracy

- ± 1 Inkrement

- Non-linearity max.

- ±1°

- Connection

- M12x1-Male, 4-pin

- Speed max.

- 600 1/min

- Interface

- IO-Link 1.1

- Housing material

- PA 12

- IP rating

- IP69K, IP68

- Approval/Conformity

-

CE

UKCA

cULus

Ecolab

WEEE

Visualization of the individual changeover points

- Principle of operation

- Indicator light with optical sensor

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 6

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Color circle mode - Setting

- Function indicator

- Additional function

- Daisy chain (2x devices per IO-Link port)

- Range

- 100 mm, adjustable

- Dimension

- 61.8 x 62.4 x 57.5 mm

- Housing material

-

PC, Transparent

PPS - Mounting part

- Screws M22

- Ambient temperature

- -5...55 °C

- IP rating

- IP67

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 8.4 ms

- Process data IN

- 2 bytes

- Process data OUT

- 8 bytes

Further application examples in the field of calendering

Discover more topics

Downloads

-

Industry brochure battery industry