Object Detection for Intralogistics / Warehousing Applications

Explore the four key object detection sensors powering smarter, faster, and more reliable intralogistics automation

Reading Time: minutes

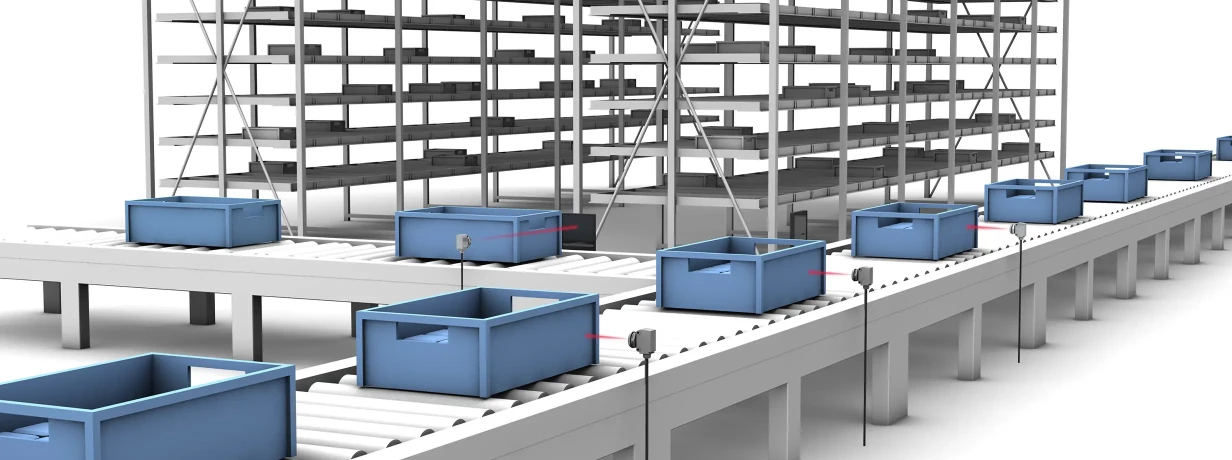

We’ve published several blogs in our “Automation for Intralogistics” series; this latest installment focuses on a foundational technology: object detection. From tracking totes on conveyors to monitoring fill levels in containers, object detection is central to efficient and reliable warehouse automation.

Four types of sensors used in intralogistics

The four main types of objection detection sensors – photoelectric, inductive, ultrasonic, and capacitive – are widely used across intralogistics applications, including conveyors, shuttles, autonomous mobile robots (AMRs), and storage and retrieval systems. These sensors enable accurate, real-time object detection, providing essential feedback and data to optimize performance and reduce downtime.

Photoelectric sensors are the most commonly used object detection sensors in warehouses, detecting presence, distance, color, height, and fill level. They are used to identify items such as totes, boxes, or materials on conveyors, check loads on shuttles or AMRs/AGVs, and verify the presence of items in storage systems or containers. These sensors come in various shapes and sizes, including cylindrical, rectangular, and fork designs, and use different detection technologies such as through-beam, diffuse (with or without background suppression), retroreflective, color and distance sensing. Light sources can include red or blue light or lasers. Selecting the “best” photoelectric sensor for a given intralogistics application depends on factors such as object distance and speed, available mounting space, and object characteristics like color, surface finish, and size.

Inductive sensors detect metallic objects such as carriers, pallets, and metal parts, as well as monitor the position of equipment like robots, shuttles, sorters, diverters, and gantries. As non-contact sensors, they are free from wear and tear. In addition to standard sensors, there are versions with extra switching distance, weld immunity, the ability to detect different types of metals (factor 1), and designs suited for hygienic, high-pressure, or hazardous areas. They come in cylindrical and rectangular shapes. Selection criteria include the type of metal to be detected, sensing distance to objects, available mounting space, and operating environment.

Ultrasonic sensors can be used for collision avoidance, detecting fill levels, position sensing, distance measurement, and detecting solid, powdered, or liquid media. They are excellent for non-contact monitoring and are impervious to mist, dust, and dirt. Common applications include AMRs, AGVs, shuttles and carriers to avoid collisions, monitor container fill levels, and detect stock levels on racks and shelves. The sensors come in cylindrical or rectangular housings and various sizes. Key selection factors include the sensing distance, available mounting space, and the specific type of application.

Capacitive sensors can detect a wide range of materials, including both conductive and non-conductive substances, using either direct or non-contact sensing methods. They are commonly used for level detection in containers holding liquids, powders, and granular materials. Capacitive sensors are also suitable for detecting the presence of pallets, boxes, and other items on conveyors or in storage systems, especially in challenging environmental conditions. Housing options include tubular, disk, rectangular, strip, and compact sensor heads with separate amplifiers. Selection depends on the application or purpose, the detected media, and the available mounting space.

Smart versions of these sensors are available that incorporate capabilities beyond their core functions, including parameterization, self-diagnostics, and condition monitoring. Using the common and open IO-Link standard, these smart sensors can communicate enhanced information, including boot cycles, switching counters, signal quality, operating hours, vibration, and temperature.

Selecting the right sensor for your application

Although choosing a sensor can seem challenging, the range of options can be quickly narrowed by considering the key attributes of the application. Here are some questions to consider:

Is there a sensing technology already in use? If so, does it work well or are there any shortcomings?

What material is being detected? Is the object metallic or non-metallic? Clear or opaque? Is the surface rough or smooth, reflective or dull? Is the object solid or liquid?

How far away is the object?

Is the object stationary or moving? If moving, how fast?

Where will you mount the sensor, and what form factor is needed?

Are there any environmental challenges? For example, do you need to consider weld spatter, extremely low or temperatures, washdown processes, or explosion-proof certification?

What output signals are required? PNP or NPN? Normally closed (NC) or normally open (NO)? IO-Link?

How will the sensor be connected?

Are there any other special considerations?

For more on sensor selection, read the blog How do I choose the right sensor? | Balluff.

As critical parts of the warehouse controls hierarchy, sensors gather the basic data required for real-time control of conveyors, robots, shuttles, and storage systems. Smart sensors can also provide the basic process diagnostics for machine health, condition monitoring and Overall Equipment Effectiveness. Selecting the appropriate sensor for your applications can be simplified by asking the right questions and by consulting a sensing expert.

Keywords

- Intralogistics

Author

Tom Knauer

24 Contributions

Comment

Popular posts

Industrial sensing fundamentals – NPN vs PNP

What is a capacitive sensor?

How do I wire my 3-wire sensors?

The basic operating principle of an inductive proximity sensor

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff Inc.

-

8125 Holton Dr.

Florence, KY 41042