- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

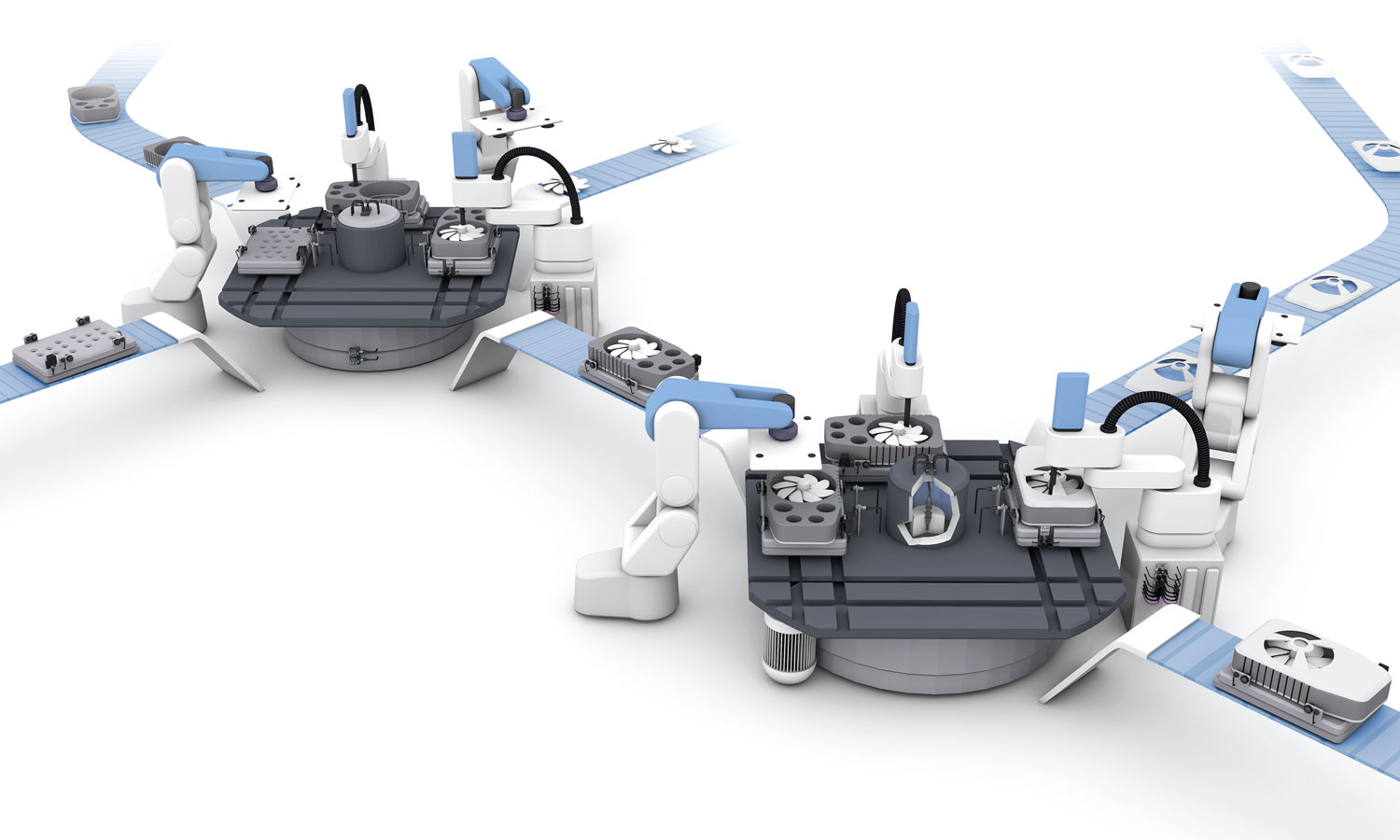

- Smart Automation and Monitoring System

- Architects of Smart Manufacturing

- Comprehensive components and solutions for automated welding

- Level Detection

- Explosion Protection

- Quality Assurance

- High Durability

- Miniaturization

- MicroSPOT

- Condition Monitoring

Application scenarios of SAMS in industry scenarios

The Smart Automation and Monitoring System portfolio can be used in many ways

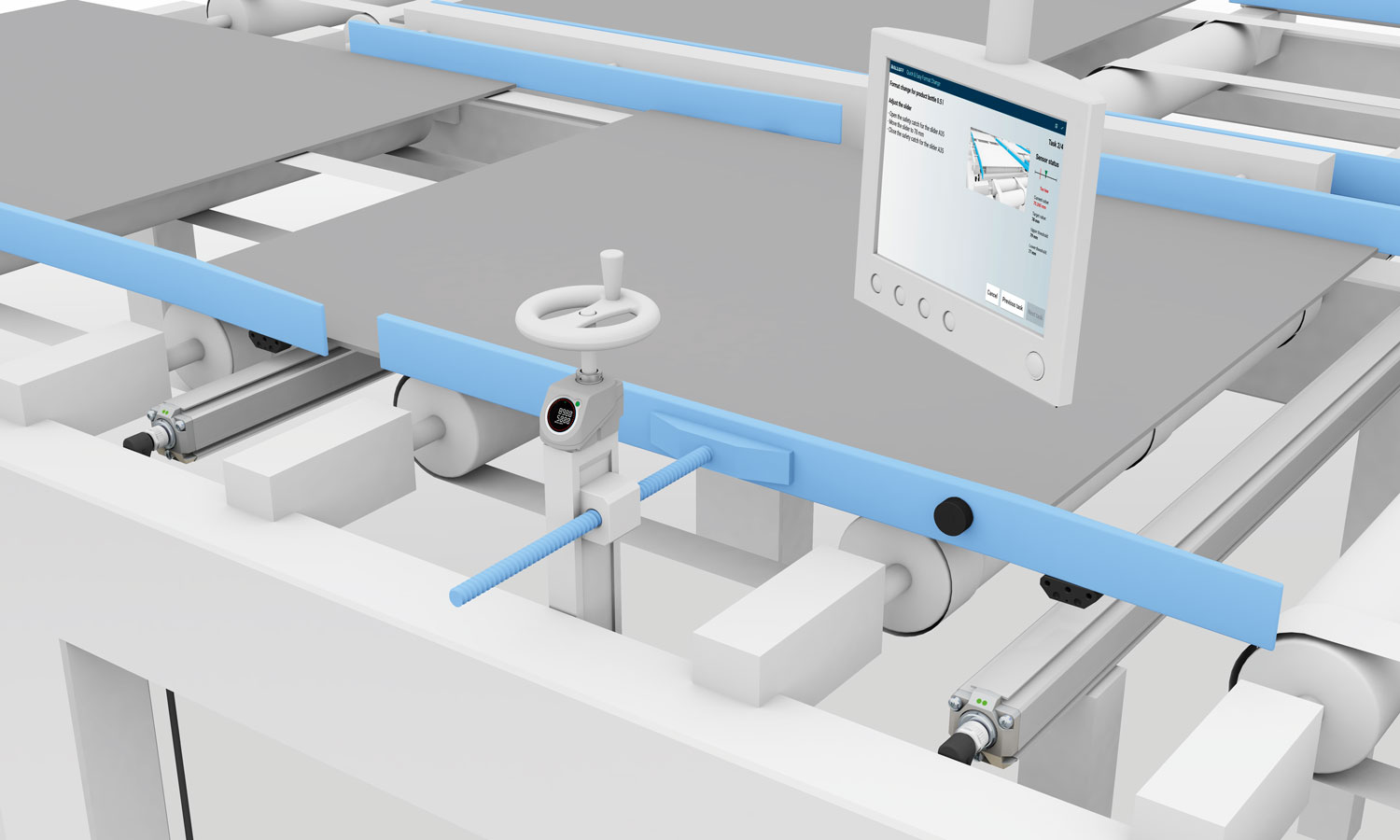

Digital position indicator for format changeover

The digital position indicator (DPI) is part of the Smart Automation and Monitoring System (SAMS), so it has a large number of sophisticated sensors built into the product.

With the DPI from Balluff, you can quickly make accurate machine adjustments for a wide variety of products and ever-shrinking batch sizes. This is because our position indicator offers you clear operator guidance for semi-automated format adjustment.

Optical sensors in automotive tire production

Automotive tire production is a comparatively dirty environment in which cleaning is often required. During cleaning processes, there is a risk of sensors being accidentally misaligned.

With SAMS, the sensor reports that it has been misaligned and even by how many degrees. This makes it easy to reposition the sensor correctly and thus avoid reject production (increasing OEE). Contamination of the sensor itself can also be detected. This tells you that the sensor is losing signal quality and needs to be cleaned.

Inductive couplers for wireless power transmission

Inductive couplers are now indispensable in a wide range of applications.

Thanks to their contactless transmission of data and power, they have long since surpassed mechanical connectors and slip rings.

With the smart functions of SAMS couplers, the temperature, for example, can also be monitored.

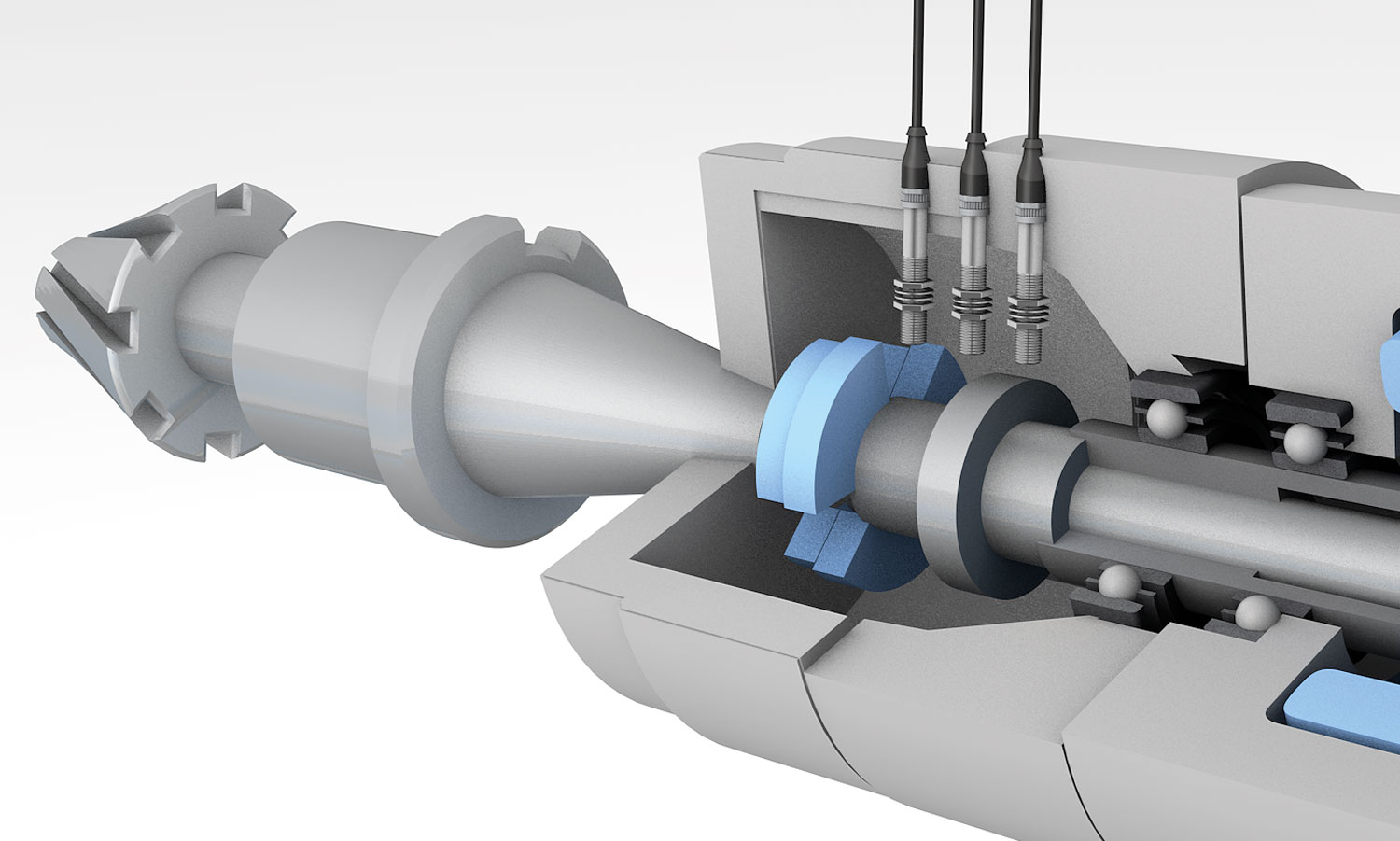

Inductive sensor on tool spindles

For spindles in machine tools, only a little or no information is available about the current status and key measurements of the spindle, in most cases.

SAMS sensors, which detect the clamping condition of the machining tool, can be used to read additional information to the machine tool such as the number of clamping cycles, the temperature in the spindle and vibration.