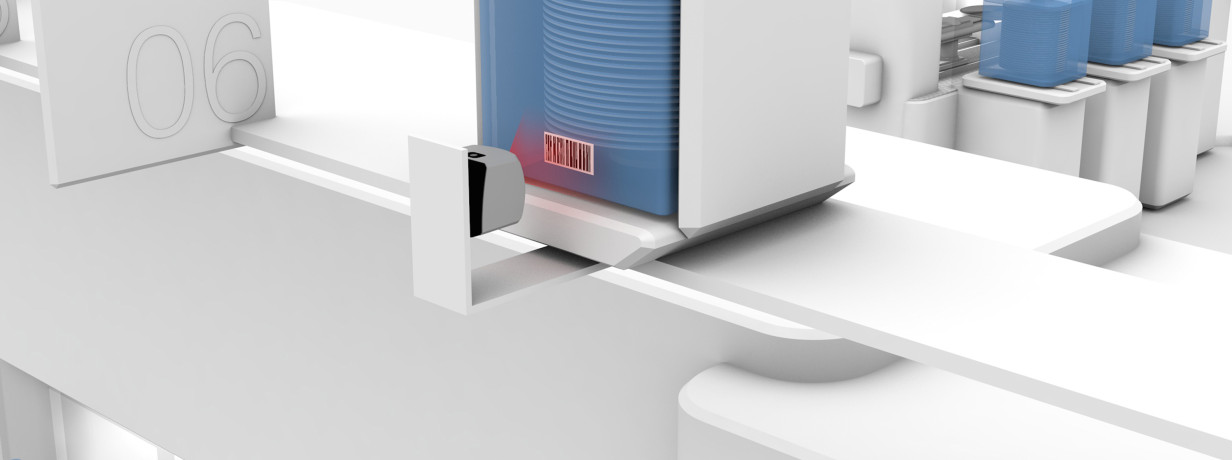

Choosing the right code reader: Laser versus vision

Evaluate vision-based and laser-based barcode readers to optimize performance

Reading Time: minutes

When choosing a barcode reader, the first step is to select between vision-based or laser-based reader options. Each option has its own pros and cons that are worth considering. Assuming that the goal of any code reader is to maximize read rate and minimize errors, it’s easy to evaluate each technology separately.

Laser-based readers

Laser-based readers use a red laser diode and a rotating mirror to scan each barcode and create a raster image, like how old CRT TVs would display an image on the TV screen. You may remember this from older grocery store checkouts, where red laser lines projected up through a transparent glass pane. One obvious disadvantage of this is that operators don’t typically enjoy dealing with lasers, as no one likes getting a laser to the eye, even if it’s a low-energy laser device.

Another, maybe less obvious, disadvantage is that these rotating mirrors can present a common failure mode, especially in applications with high shock or vibration.

So why choose a laser scanner? The answer lies in its depth-of-field capability. Laser readers out-perform their vison-based counterparts in extremely short ranges (less than 1-2″ from the sensor face) and when the distance from the sensor to the code varies by more than about 3 feet. In these cases, the rotating mirror and highly coherent laser can improve read rates.

Vision-based readers

Now, let’s turn our attention to vision-based readers. These function just like any regular camera, but their image processing methods are what make them interesting. They snap pictures at high speeds and use vision algorithms to find and decode barcodes. One significant advantage is the simplified alignment and setup, as you can see exactly what the code reader sees during the setup process.

Modern code reading algorithms enable not just 1D codes but also 2D, Datamatix, QR, and many other symbologies that 1D readers can’t read. Moreover, vision-based readers can interpret codes regardless of their rotation or orientation. Additionally, vision-based readers offer added benefits for code quality assessments and auditing. Pictures of the product and codes can be sent over the network and saved for later review. Quality algorithms can assess barcode grades and identify damage and print quality issues, while advanced reconstruction can read even severely damaged codes.

Considering these factors, vision-based readers will often emerge as the logical choice, especially given the explosion of new product releases in recent years. With all this new development, there has also been considerable progress made in standardizing code-reader communications. Many vision-based readers now support a growing consensus of open standards. There are ethernet-based options supporting REST and MQTT, as well as IO-Link devices for remarkably easy installation and integration into existing machines and standard sensor architectures. This level of compatibility is not easy to find in an old laser-based reader.

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.