Enhancing pharmaceutical quality control with AI-driven camera systems

Faster tests, more reliable results, maximum safety

Reading Time: minutes

Introduction

In the pharmaceutical industry, it’s important to ensure the highest standards of quality and safety. Whether pills, capsules, or other dosage forms: any error in the production process can have serious consequences and entail not only financial but also health-related risks.

Traditional image processing systems often fall short in complex scenarios, leading to inefficiencies and potential risks. This case study shows how pharmaceutical manufacturers can revamp its quality control process by integrating an AI-based quality control solution.

The Challenge

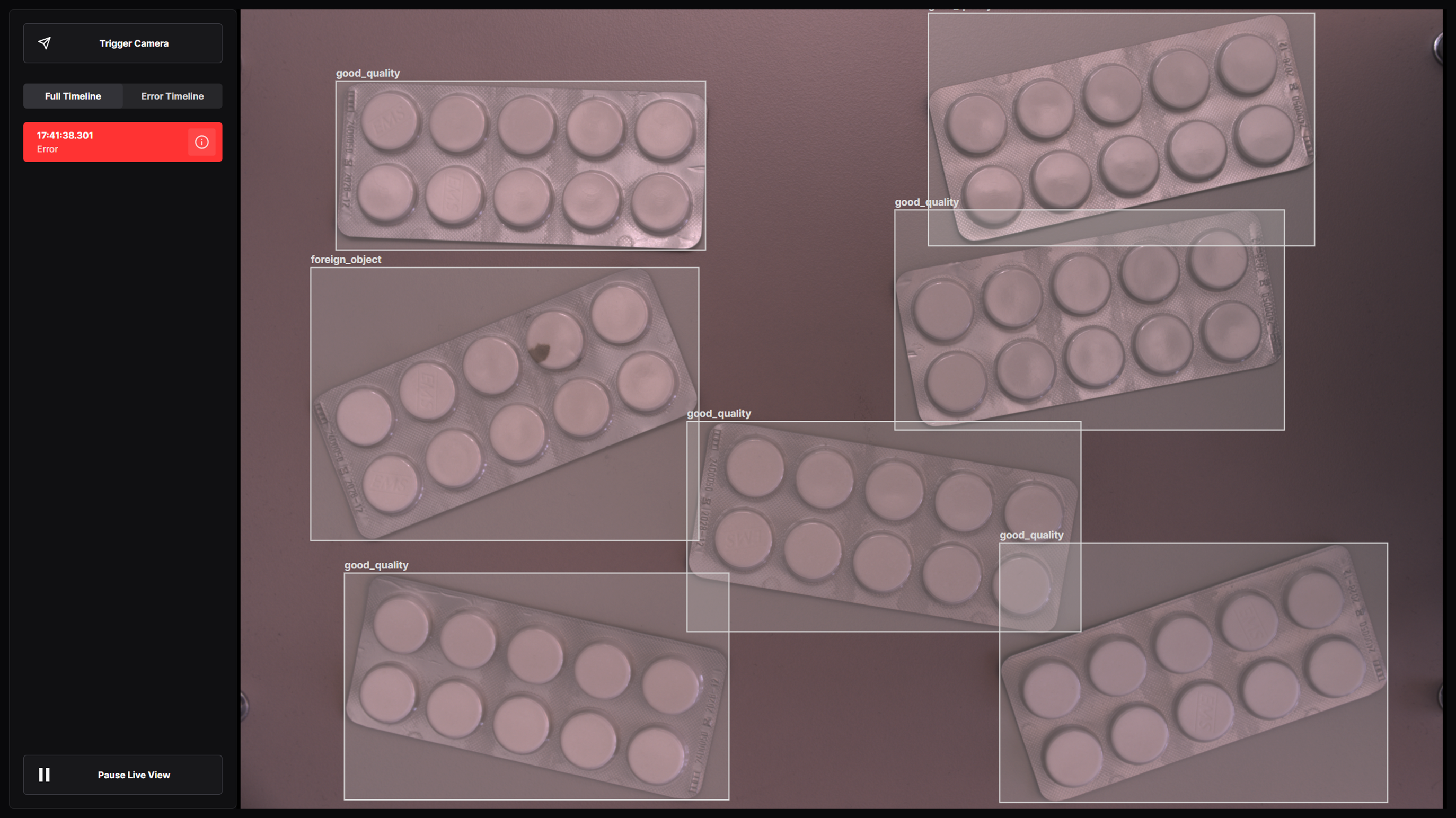

Pharmaceutical production demands precise quality control. Defective pills—whether due to fractures, discolorations, contaminants, or even empty cavities where a pill is completely missing—can incur significant follow-up costs for the company.

Traditional rule-based image processing systems struggle with subtle variations in colour and shape, resulting in high error rates. This leads to unnecessary disposal of intact products and the risk of defective products slipping through.

With conventional image recognition, an explicit set of rules would need to be defined for every possible manifestation of a defect. This causes enormous programming and maintenance expenses, especially considering that production conditions (lighting, positioning, etc.) often change over time. Under these circumstances, quality management faces a daunting challenge.

Most pharmaceutical manufacturers were using conventional image processing systems based on fixed rules before switching to an AI-based solution. The camera was configured so that the following criteria were automatically checked for each product run:

Completeness: Is the pill present in each cavity, or is it missing?

Breaks and chips: Are there any structural damages to the pills?

Foreign objects: Are there visible particles or residues that do not belong to the pill?

Manual checking of rejected pills

For a company, this meant a high manual workload afterwards: employees had to review the supposedly rejected pills, only to discover in many cases that there was no actual defect. This process consumed valuable time, slowed production, and led to higher unit costs. As a result, the status quo was no longer optimal in terms of productivity, workload, or process reliability.

Solution and implementation

The manufacturer implemented the ANTICIPATE software, connected to existing cameras, to address these challenges. The AI-based system uses a neural network to learn and detect errors through image data. This approach allows for flexible detection of defects, even under varying lighting conditions.

For the camera the decision was made to use a 20,5 MP GigE Vision camera with Sony Starvis CMOS sensor IMX183 from Balluff: BVS CA-GX0-0205ZC. The Starvis image sensor, with a pixel size of 2.4 µm, enables high image quality, crucial for AI-driven defect detection. As a back-illuminated sensor, it offers high light sensitivity and absorption, allowing for shorter exposure times. The optimized on-chip lenses reduce random noise, dark current, and defective pixels, further enhancing sensitivity and noise performance.

This camera was chosen for its robust design and reliable Gigabit Ethernet connection via Power over Ethernet (PoE). This simplifies the setup and reduces overall costs, as a separate power supply is no longer necessary.

Supported by Intel, the solution runs on Intel® Core™ i5 Processors, Intel® RealSense™ Depth Camera D435f and using Intel® OpenVino™ Toolkit.

Enhancing pharmaceutical quality control with AI-driven camera systems

Results

The AI-driven camera system brought significant improvements to the pharmaceutical manufacturing process:

High detection accuracy: The AI system's ability to detect even the smallest deviations drastically reduced the rejection rate of "real" defects, leading to more efficient use of production capacity.

Elimination of labor-intensive rule adjustments: The AI adapts by being trained on new data, eliminating the need for intervention by image processing experts.

Seamless integration into existing processes: Errors can be reported directly, and production lines can be stopped in the event of a serious error, saving time and resources.

Reliable documentation: The automated system stores images and test results, ensuring products leave the plant in perfect condition.

Reduction in false positives and negatives: Increased precision led to higher productivity and a drastic reduction in the need for manual checks.

Cost savings: Significant savings in rework costs, staffing costs for inspection, and production downtimes.

Employee satisfaction: Greater efficiency and higher employee satisfaction across departments.

Scalability and flexibility: Expansion to other processes and product variants without major additional expense.

Furthermore the AI-driven camera system drastically reduced false positives and negatives, improving productivity and reliability. The benefits included high detection accuracy, elimination of labour-intensive rule adjustments, seamless integration into existing processes, and reliable documentation. The system led to significant savings in rework costs, staffing costs for inspection, and production downtimes.

The economic calculation: savings and amortization

In this project the introduction of an AI-based solution at several inspection stations was carefully evaluated for profitability and Return on Investment (ROI). The cost structure included one-time implementation and hardware expenses for each station and annual software costs. In this case, four stations were needed, with total one-time costs amounting to €120,600 and annual software costs of €14,400 for four systems. Savings were realized by utilizing existing camera infrastructure for two stations, reducing hardware costs by €6,000 per station.

Internal calculations indicated substantial savings of about €180,000 annually from reducing false rejects and relieving manual inspectors. The total investment for this example, including implementation, hardware for two new stations, and the first year’s software costs, amounted to approximately €135,000. This resulted in an amortization period of around nine months, demonstrating a significant financial benefit in the first operating year. The implementation of AI-based inspection systems not only improved quality but also proved to be an economically sound investment.

Further use in other industry sectors

Although the example described is specifically tailored to pill manufacturing, an AI-based image processing system has a wide range of applications. This is because the fundamental challenge—precisely detecting defects in a highly variable environment—occurs in many industries:

• Automotive: Weld points, paint defects, completeness of components.

• Food: Foreign objects, incorrect labelling, unusual shapes.

• Electronics: PCB inspection, component placement checks.

• Packaging: Incorrect labels, damage, barcode readability.

Keywords

- Camera

- IO-Link

- Vision

Author

Balluff EMEA

We are your partner for innovative solutions in industrial automation. With our passion we improve your competitive position with speed and results. With our 100 years company history and more than 60 years of sensor experience, Balluff is a world leader and one of the most efficient manufacturers of sensor technology.

30 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.