- Matrix Vision solutions now all under the Balluff brand

- Condition Monitoring

- Smart Automation and Monitoring System

- IO-Link: Intelligent solutions for modern automation

- Architects of Smart Manufacturing

- Explosion Protection

- Level Detection

- MicroSPOT

- Miniaturization

- Tough Performers

- Quality Assurance

- Comprehensive components and solutions for automated welding

Condition Monitoring

Continuously monitor the condition of machines, plants and processes

Stop guessing, start knowing

Condition monitoring systems and their components contribute to the efficient and trouble-free operation of machines and plants. With them, you know the current status and can make informed decisions for the future - and don't have to keep guessing.

Increase performance:

Increase plant availability

Increase product/process quality

Increase plant service life

Efficient monitoring

Cost reduction:

Reduce repair costs

Reduce maintenance and service

Reduce spare parts stocks

Process optimization:

Plannable and efficient maintenance

Uncomplicated part replacement

Easily identify defective sensors

Create added value:

As an OEM for your customer.

Reduce maintenance and service

Improve quality of machines

Disruptions in the production process due to unplanned downtimes can be prevented through the use of sensors. Monitoring sensors, such as temperature, pressure and level sensors, provide data on the condition of a plant. If this data is processed, it provides valuable information for the maintenance of the machines and thus enables successful preventive maintenance.

The benefits of condition monitoring

Condition monitoring systems allow changes, such as wear on individual components or decreased sensor performance, to be detected more quickly and machine maintenance to be better coordinated.

This optimizes the maintenance process and also increases safety for your employees. Furthermore, failures can be anticipated to avoid or minimize production delays and the costs that come with them.

Beyond these possibilities, the extensive information and data provided by condition monitoring systems offers the possibility of new business and pricing models for machines and plants.

Produce more

Less downtime

First step towards predictive maintenance

Employee safety

Five facts that will boost your production

Are you still guessing or do you already have experience with condition monitoring? We have prepared additional information about this topic and would like to make this available to you - based on your knowledge.

For beginners: Start your knowledge building with the top 5 facts about condition monitoring and learn about maintenance approaches and gathering the right data. We also answer the often asked question about cost-benefit tradeoffs, and provide an example calculation of return on investment - find all that in our PDF fact sheet.

For advanced: Deepen your knowledge with more details. Example applications show you where and how condition monitoring can bring you real benefits. And our easy guide can help you choose the right solution and sensor for your individual requirement - find all that on your digital whitepaper.

Not sure about your level of knowledge? Use our self-assessment with just six questions and we will send you the right content based on your answers.

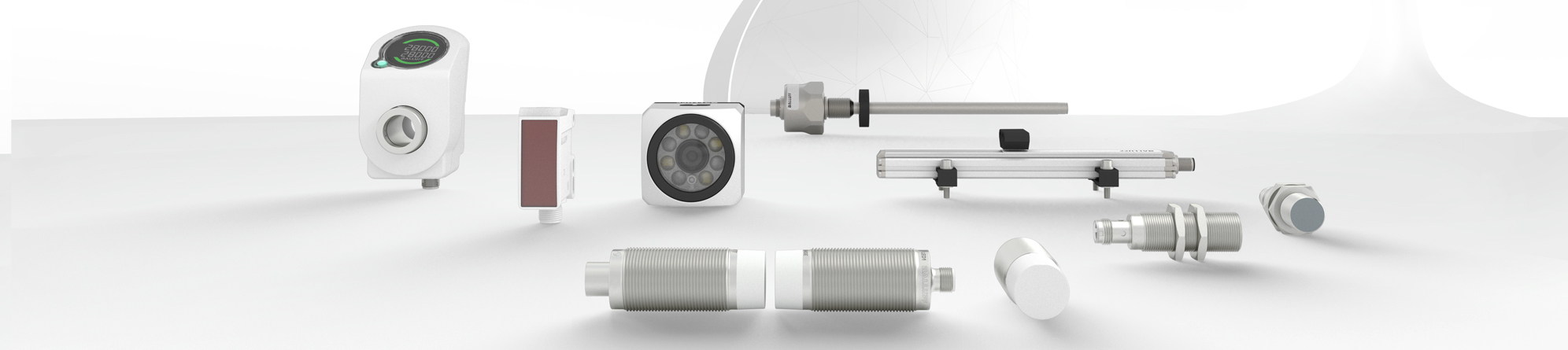

Balluff Condition Monitoring: A comprehensive portfolio that sets standards

With a broad and systemically comprehensive range, Balluff offers suitable solutions for the efficient analysis of your machine data: From sensors that provide additional data for efficient condition monitoring through IO-Link, to standard systems with extensive analysis options and evaluation software, to customised overall solutions. From evaluation to concept to implementation - we are the right partner from the very beginning and will be happy to accompany you.

Our customers solve complex problems in industrial production every day. We aim to make their work easier and more efficient. Our sensors provide valuable data about machines that increases reliability in the automation process and drives improvement. Our customers have benefitted from our solutions -- from simple to complex --for many years and we'd be happy to support you in implementing them as well.

Thomas Meissner, Strategic Incubation Manager at Balluff

Our technology for your success

Condition detection, analysis, diagnosis:

In addition to their original function, like distance measurement or object detection, the components of the Balluff Smart Automation and Monitoring System (SAMS) provide you with condition data like vibration, temperature or operating hours. The best part: thanks to the IO-Link communication standard, the data you need is available uniformly everywhere, and as soon as you need it.

Learn more about the functions of the components of the Smart Automation and Monitoring System.

A condition monitoring solution in an intelligent sensor

In addition to the SAMS components, Balluff offers an intelligent condition monitoring sensor. The condition monitoring sensor measures various physical variables - such as vibration, temperature, humidity and ambient pressure - and supplies the recorded data to a higher-level system via IO-Link. The data obtained can be used not only for plant control, but can also be further evaluated and analyzed for diagnostic purposes. In addition, the sensor offers the possibility of defining limit values for pre-alarms and main alarms, so that certain states generate warning messages as soon as the defined values are exceeded. After evaluating the collected data, statements can be made about the condition of the machines and systems. Together with the warning messages, this data pool is a prerequisite for predictive maintenance.

Multiple measured variables in one device: vibration, temperature, humidity, ambient pressure

Integrated evaluation electronics with configurable data preprocessing

Configurable events and status displays

Quick to connect and easy to integrate via IO-Link

Compact design

Condition Monitoring Toolkit (CMTK)

With the Condition Monitoring Toolkit (CMTK), we offer you a complete solution to monitor the condition of machines and processes. It contains everything you need: from sensors to data acquisition system to visualization software. And you benefit from great flexibility thanks to its compatibility with all IO-Link sensors, as well as simple operation thanks to the intuitive software. Thus, with the CMTK, you can implement condition monitoring entirely according to your needs in just a few minutes.

You need help?

Please contact us - we will be happy to support you!Downloads

-

Industry brochure condition monitoring – continuously monitor the condition of machinery