Quality Assurance

Prevent errors in the manufacturing process

The demands for quality placed on manufacturers have been high for years and continue to increase. It no longer suffices to manufacture a high-quality product. Rather, it is expected that quality products are delivered just in time and, above all, subcomponents in the right order. Furthermore, production should be transparent for everyone involved through transparency of the products.

Since quality is a continuing, fundamental parameter in every production process, workflows must continually be improved and everyone involved must contribute to quality assurance early in the process.

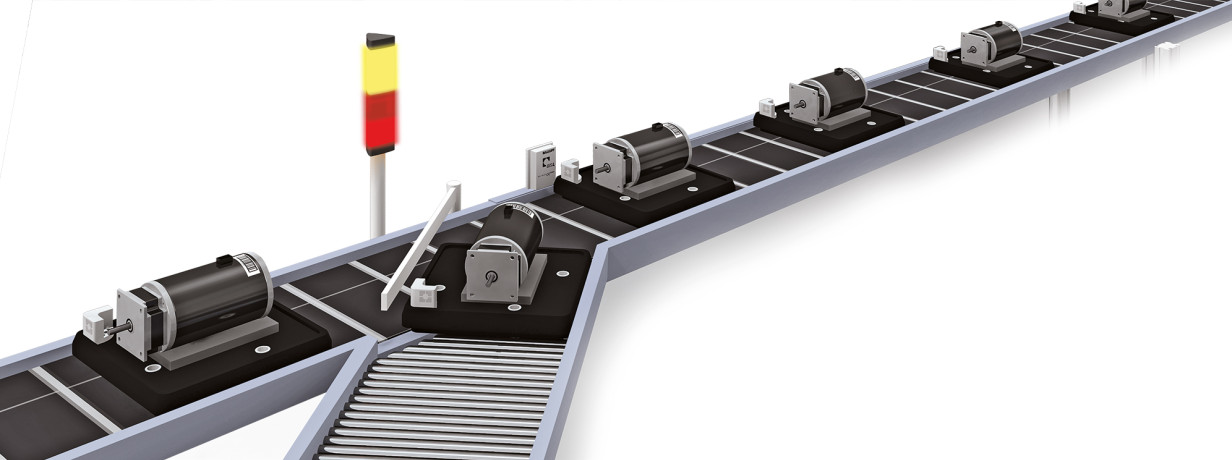

The process is made traceable by solutions for error prevention that are integrated into the process itself. These kinds of poka-yoke solutions can be implemented with our sensors. In addition, precautions must be taken that enable quick adaptation to changed requirements.

Poka-yoke from Balluff enables continuous quality by identifying problem areas, implementing error recognition and controlling deviations.

Products

Products