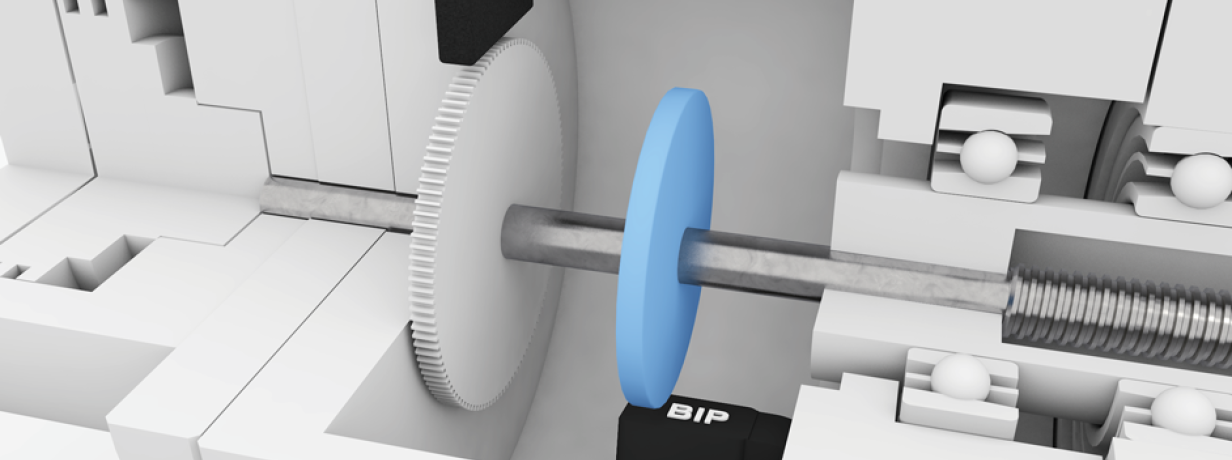

Clamping distance monitoring on tool spindles

Is the tool clamped in the spindle? Is there a tool in the spindle or not? Modern metal machining centers typically have tight mounting conditions, a difficult requirement for many position measuring systems. Fortunately, the smallest versions of our BIP inductive positioning system measure just 14 and 17 mm, so they can be used in even the tightest spaces. They are ideal for monitoring the clamping mechanism on tool spindles. Clamping distance monitoring can even be accomplished when the clamping mechanism rotates. Here the BIP detects the position of a metallic cam as it passes laterally by the sensor. An adjustable measuring range and high repeat accuracy ensure optimal process quality. Versions with an IO-Link interface enable simple wiring, diagnostics on-the-fly down to the field level, and automatic parameter setting.

Products

Products