- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Life Science

- Drive Technology

- Steel and Metallurgical Industry

- Mobile Equipment

- Efficient metalworking using sensor and automation technology

- Plastic Industry

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- Automobile industry and suppliers

- Energy Production

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Intralogistics automation: improve efficiency and throughput

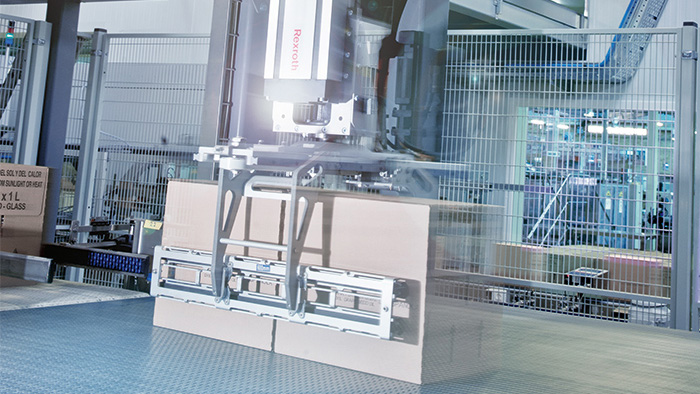

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

Optimizing OEE and process efficiency in key packaging application areas

The Packaging, Food, Beverage, Pharma, and Daily Care industries face a unique set of challenges, from stringent regulatory compliances to increasing consumer demands for higher quality and sustainability. The comprehensive nature of these industries, extending from raw materials handling to production, packaging, and intralogistics, brings forth complexities that demand innovative and efficient solutions.

Improving Overall Equipment Efficiency (OEE) becomes critical in this landscape, ensuring you're getting the most from your assets. At Balluff, we specialize in offering sensor technology and automation solutions that elevate your OEE and bring about transformative improvements in your packaging processes. Our solutions address key pain points – from achieving precise quality control and optimizing high-speed production lines to ensuring flawless condition monitoring.

Discover your industry of interest

Maximizing OEE: a comprehensive industry guide

Revolutionizing OEE in packaging food and beverage

Practical techniques and real-world solutions to boost productivity and minimize downtime

Efficiently navigate the packaging, food, and beverage industry with our expert OEE guide. Uncover effective strategies to minimize unplanned downtime, streamline changeovers, and capitalize on IIoT and smart technologies.

In this guide, we delve into seven core application areas: controls architecture, format change, predictive maintenance, level sensing, robotic automation, and quality assurance, providing you with practical insights to boost your packaging processes.

Spotlight applications to boost productivity

Discover select applications that offer insights into how we tackle specific challenges within the packaging, food, beverage, and personal care industry. Many more waiting for you to be explored in our application database.

Success in action: case studies that inspire

Browse these concise instances of our impactful solutions within the packaging, food, beverage, pharmaceutical, and personal care industries. See real-world effectiveness and gain insights for your own operations

Trimming changeover times by 65% using Guided Format Change

Discover how efficient changeovers were achieved by introducing IO-Link sensors for a guided format change retrofit, resulting in a significant decrease of time required and a boost in Overall Equipment Effectiveness.

Resilient performance: sensor and networking products built to last

Meeting varied demands of the packaging, food and beverage industry, our range of resilient, washdown networking and sensor solutions ensure uninterrupted, safe operations, ensuring maximum OEE.

Special focus: high-pressure washdown

Ensuring top-notch quality isn't solely about the manufacturing process; the equipment you use plays a crucial role too. Balluff's IP69K sensors are engineered for high-pressure washdown applications, making them ideal for cleanliness-critical industries like food, beverages, pharmaceuticals, and cosmetics.

Highlights

- Designed for demanding cleaning and disinfecting cycles

- Exceeds IP69K standards with a rating of at least 1000 cleaning cycles

Reliable and rugged

Beyond the sensors, Balluff's "Washdown Plus" feature ensures that enclosures and control cabinets are exceptionally reliable under harsh conditions, meeting and even exceeding Ecolab and IP69K standards.

For more information, check out our washdown brochure.

Questions? Get in touch!

Downloads

-

Industry brochure filling and packaging Industry

-

Products for packaging, food and beverage for food safety

-

Revolutionizing OEE in packaging food & beverage