Is a photoelectric sensor best for your label detection application?

Common label detection applications you can solve with just a photoelectric sensor

Reading Time: minutes

Label detection is in every industry of manufacturing. Detecting the placement, orientation, color, or size of a label is critical to product quality and it can even be required for safety purposes. Contrary to what some believe, not every label detection application requires an expensive vision system. This article reviews some common applications that can be solved with just a photoelectric sensor.

As with any sensor application, it’s necessary to specifically tailor the systems for individual applications. In label detection, the label properties dictate the necessary sensor for the job. Using the right sensor will ensure accuracy to the manufacturing process by limiting the possibility of errors or misreads when placing or cutting off the label. The chance for mistakes decreases when labels are designed to have markings used as a point of reference for the sensor to recognize, telling the PLC programming that it is time to cut off or place the label. When looking into a label detection application, several photoelectric sensor types are available.

Through-beam fork sensors

A through-beam fork sensor has an emitter and a receiver built into the same housing which provides a consistent light beam that is simple to configure to many applications. For label detection, fork sensors have teach-in buttons to set the target and background so unique markings can trigger the sensor. This helps find an identification marker that can identify where to cut the label. For applications with consistent markings on different labels, the sensor would not need to be retaught if the color of the identification mark and the background are the same. The common use for these sensors is on flexible manufacturing lines because operators can reteach the sensor to recognize a new label with a different style and color in less than 60 seconds.

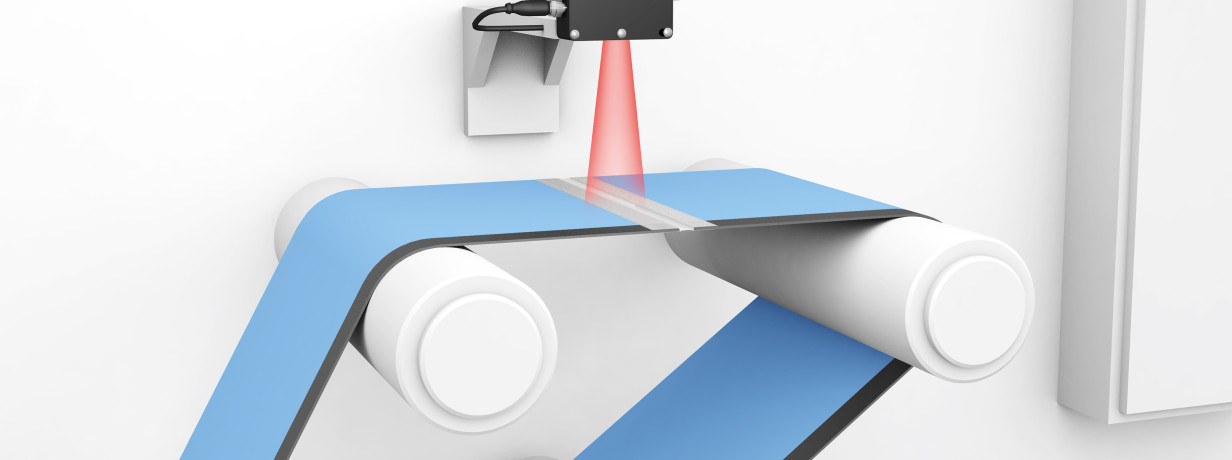

Contrast sensors

Providing a high level of accuracy to find labels in an assortment of products, contrast sensors can be taught to identify a target on many different material types, providing an advantage when working with three-dimensional objects. They provide background suppression, allowing for applications using transparent objects, such as glass and plastic and work by distinguishing between objects based on their gray values. This means contrast sensors are highly accurate when detecting objects with similar colors.

Color sensors

Color sensors

Color sensors are a fantastic choice when working with labels with many different colors. A traditional color sensor can be taught to up to 7 different color parameters to distinguish one label type from the others. Manufacturers with multiple production lines that have labels with various colors can use just one color sensor to detect them all. The more advanced IO-Link-capable color sensors provide an abundance of opportunities to configure many different label types. Using color detection software, one color sensor can be taught up to 256 different color parameters. Users can configure each color setting for the label’s colors and the background.

When it comes to selecting the right sensor for your label detection, you have options. You need to consider the specifics of your application and choose the solution that ensures accuracy and quality during the manufacturing process.

When it comes to selecting the right sensor for your label detection, you have options. You need to consider the specifics of your application and choose the solution that ensures accuracy and quality during the manufacturing process.

Keywords

- Sensor technology

Author

Will Fumich

3 Contributions

Comment

Popular posts

Industrial sensing fundamentals – NPN vs PNP

What is a capacitive sensor?

How do I wire my 3-wire sensors?

The basic operating principle of an inductive proximity sensor

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff Inc.

-

8125 Holton Dr.

Florence, KY 41042