Basics: What's the value of IO-Link?

Analytics and diagnostics are crucial for predictive maintenance, enhancing equipment effectiveness, and monitoring machine condition

Reading Time: minutes

With the demands for flexible manufacturing, efficient production, and visibility in our factories, smart manufacturing is driving the way we work today. Analytics and diagnostics are becoming critical to our ability to perform predictive maintenance, improve equipment effectiveness, and monitor the condition of the machine and its components.

With the demands for flexible manufacturing, efficient production, and visibility in our factories, smart manufacturing is driving the way we work today. Analytics and diagnostics are becoming critical to our ability to perform predictive maintenance, improve equipment effectiveness, and monitor the condition of the machine and its components.

Typically, our first reaction is to put these devices onto Ethernet. However, implementing Ethernet requires a high skill set that is scarce in our traditional manufacturers today. The simple control architecture of IO-Link devices allows for many Smart devices to provide the data we need for analytics with a reduction in the Ethernet skill set that has become a roadblock for many manufacturers.

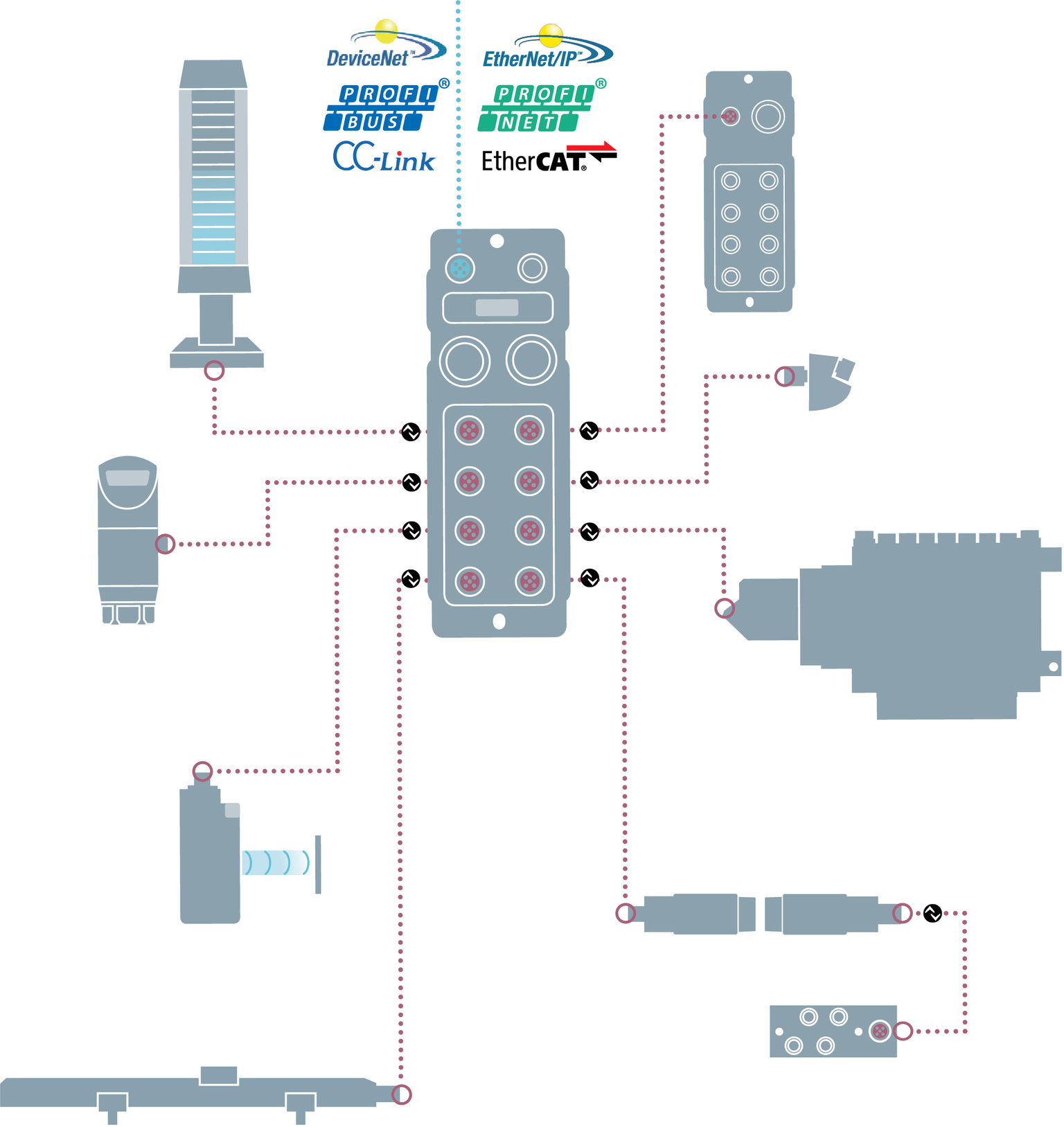

Many people think IO-Link is a new industrial network to compete with EtherNet/IP or Profinet, but this is a common misconception. IO-Link is complementary to those networks and typically enables those networks to do even more than previously thought.

Open Standard

Open Standard

IO-Link is an open standard designed with the idea of acting like a USB for industrial automation. IO-Link is meant to simplify the smart sensor and intelligent device connectivity on the factory floor similarly to USB simplified connectivity to computers for auxiliary devices. IO-Link is not an industrial network or fieldbus but an industrial network and controller agnostic. Designed with a master-to-slave configuration, the addressing of the devices is point-to-point, similar to USB. Compatible IO-Link masters can act as slaves or nodes on various industrial protocols and act complementary to the network of the user’s choosing. Eliminating the need for serial communication configuration or network addressing simplifies the connection and integration of devices.

Value in Machine Builds

IO-Link has advantages for both machine builders and discrete manufacturers. The biggest advantage for machine builders is the simplified wiring scheme of IO-Link devices. We have seen machine builder users of IO-Link reduce their wiring hardware & labor costs by 30%-60% for sensors, outputs, and controls. This is realized with the simple sensor tool cords used for connections, quick-disconnect connectors on the cables, and machine-mount Ethernet master devices. It is also realized for machine builders in increasing turns on their floor, a reduction in build labor and significantly faster commissioning time.

Value on the Production Floor

Value on the Production Floor

For discrete manufacturers, the biggest advantages have come from the parameterization and diagnostic features on the IO-Link devices. With the ability to store and send parameters between the master and slave, IO-Link devices can be automatically configured. Hot-swapping a complex smart device like a pressure sensor can go from a stressful ordeal including 14-plus setpoints to literally a push of one button. Combining this functionality with multiple diagnostics, both in the master and slaves, eliminates human error and dramatically reduces manufacturer downtime and troubleshooting.

Keywords

- Basics of automation

- IO-Link

Author

Balluff Editor

9 Contributions

Comment

Popular posts

Industrial sensing fundamentals – NPN vs PNP

What is a capacitive sensor?

How do I wire my 3-wire sensors?

The basic operating principle of an inductive proximity sensor

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff Inc.

-

8125 Holton Dr.

Florence, KY 41042