- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

- Architects of Smart Manufacturing

- Comprehensive components and solutions for automated welding

- Level Detection

- Explosion Protection

- Quality Assurance

- High Durability

- Miniaturization

- MicroSPOT

- Condition Monitoring

Track Data

Maximum transparency for the optimal process

Handle ID and process signals simultaneously

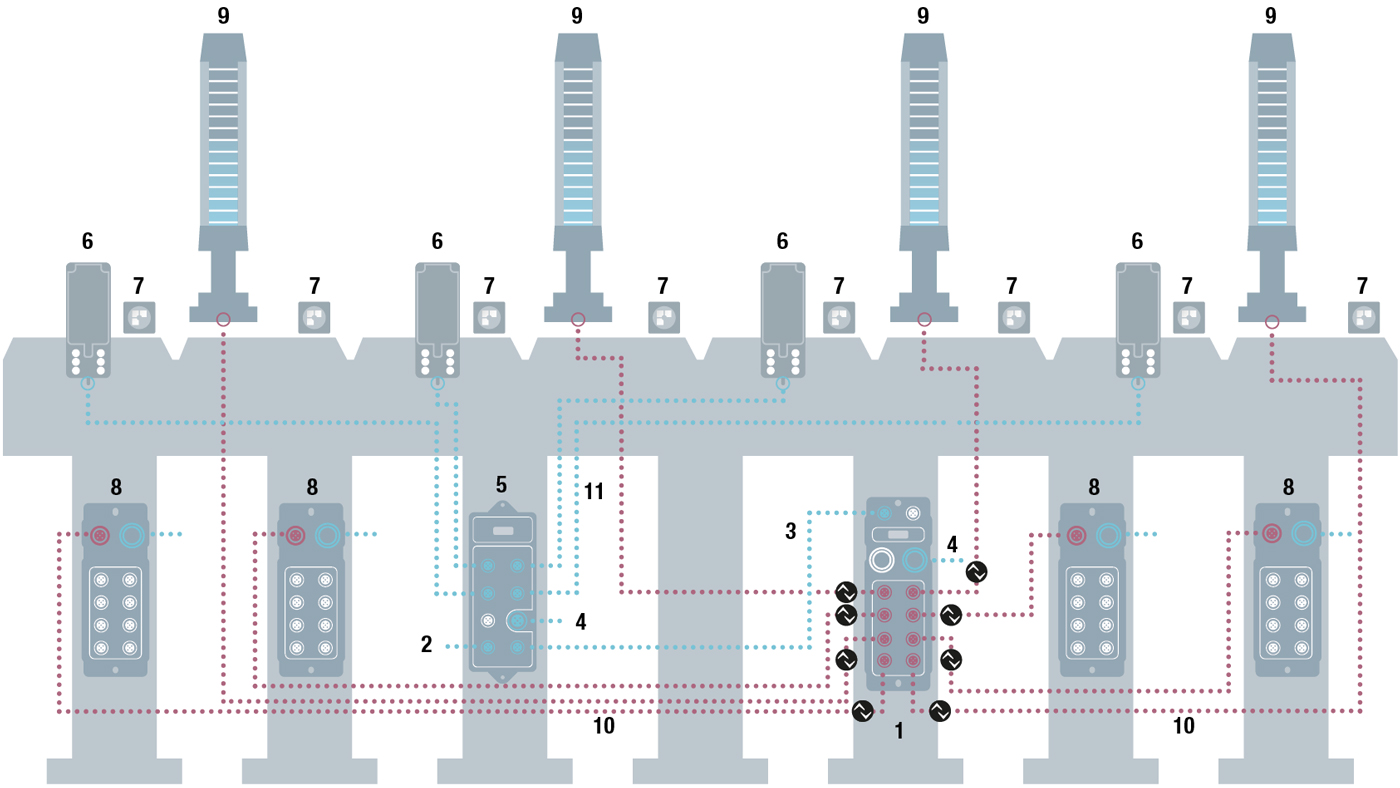

The intelligent combination of RFID and sensors with IO-Link makes it possible to cost-effectively handle your identification requirements and process signals at the same time.

When it comes to quality assurance, RFID systems record the entire production sequence and make it traceable in real time. The data is documented directly on the workpiece or pallet, regardless of ambient conditions, read distances or technologies (low-frequency, high-frequency, ultra-high frequency).

Depending on the data volume and speed, we offer different devices: BIS V processor units for fast processing of high data volumes. It also lets you run and process LF, HF and UHF read/write heads simultaneously.

An IO-Link master is appropriate for standard ID tasks to connect I/O units or IO-Link capable sensors/actuators. Each individual production step, for example, can also be displayed using the SmartLight tower light.

Related topics

Downloads

-

Performance portfolio – We speak IO-Link. Worldwide – in all areas

-

Overall Product Catalog 2019