- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

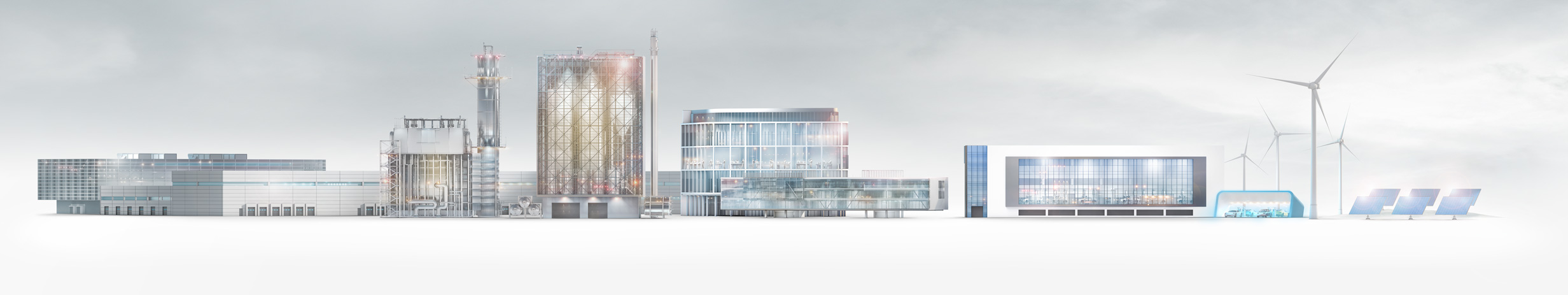

- Architects of Smart Manufacturing

- Comprehensive components and solutions for automated welding

- Level Detection

- Explosion Protection

- Quality Assurance

- High Durability

- Miniaturization

- MicroSPOT

- Condition Monitoring

IO-Link advantages

Efficient and cost-saving - the IO-Link advantage

The IO-Link communication interface offers numerous advantages that make automation more efficient and cost-effective. Overall, IO-Link offers a cost-effective, flexible and future-proof solution for industrial automation that improves both the efficiency and transparency of production processes. The following arguments make IO-Link an attractive option for companies looking to modernize and optimize their automation systems.

What are the advantages of IO-Link?

-

Simple cabling: IO-Link is easy to install

IO-Link only requires an industry-standard three- or four-core cable. The uniform standard interface can therefore be integrated into the fieldbus world quickly and cost-effectively. Even complex devices can be easily integrated. Digital communication guarantees interference immunity, even without expensive shielded cabling. Analogue signals are digitized without conversion losses. -

Simplified commissioning and parameterization: IO-Link increases machine availability

With IO-Linksensorscan be replaced quickly and without errors. Downtimes can be significantly reduced, as the parameters of a replacedIO-Link sensorfrom theIO-Link masteror the controller are automatically transferred to the new sensor. Commissioning, format changes or recipe changes can be carried out centrally via the controller. Another advantage: IO-Link devices cannot be interchanged as they are automatically identifiable via IO-Link. -

Diagnostics and monitoring: IO-Link enables demand-oriented maintenance

By continuously recording operating data and the status of the devices, maintenance requirements can be identified at an early stage and needs-based maintenance measures can be initiated. This reduces downtimes, optimizes maintenance costs and increases the overall efficiency of production processes. -

Improved data availability: IO-Link makes operation more efficient

IO-Link improves process monitoring and control through reliable data transmission. Signal delays and distortions are virtually eliminated. This is because digital data transmission ensures high signal quality. The bidirectional communication of IO-Link thus provides access to detailed sensor data and device status information that can be used for process optimization and decision-making.

Possible examples of the use of IO-Link

How does IO-Link differ from other communication standards?

IO-Link differs from other communication standards due to its specific focus on communication between sensors, actuators and controllers in automation technology. While many conventional fieldbuses such as Profinet or EtherCAT focus on the transmission of process data in real time, IO-Link offers a point-to-point connection that enables bidirectional communication between the master and the connected devices. This means that not only data can be sent, but also extensive diagnostic data and parameters can be transferred from the devices back to the master.

Flexibility and manufacturer independence

Another key difference is the flexibility of IO-Link. It supports a wide range of devices, regardless of their manufacturer, and enables the simple integration of new sensors and actuators into existing systems. Unlike other standards, which often require specific protocols and hardware, IO-Link is a manufacturer-independent standard based on existing cabling technology, thus reducing implementation costs.

Extended functions for proactive maintenance

In addition, IO-Link offers advanced functions such as the option of remote diagnostics and real-time monitoring of the device status. This enables proactive maintenance and reduces the need for manual inspections. While other communication standards are often limited to the transmission of process data, IO-Link enables comprehensive data analysis, which helps to optimize production processes and increase efficiency.

Modular control concepts with IO-Link

Control concepts with IO-Link provide universal solutions for a powerful end-to-end network and enable a flexible and scalable system architecture that can be easily adapted to changing requirements. New devices can be added easily without the need for extensive changes to the infrastructure.

The IO-Link system includes an IO-Link master and one or more IO-Link devices (sensors or actuators). The master acts as an interface to the PLC and handles communication with the connected IO-Link devices. The interface uses unshielded, three- or four-wire standard industrial cables with M8 or M12 connectors. Three wires are used as standard for the supply voltage and communication.

IO-Link sensors and actuators can be parameterized efficiently via REST APIs or the Balluff Engineering Tool (BET). With an IO-Link master that supports REST API, you can communicate directly with the devices via HTTP requests to read or write parameters. This enables flexible integration into automated systems and requires the use of API documentation and the implementation of authentication methods. Alternatively, the Balluff Engineering Tool offers a user-friendly interface for manual configuration. After installation and connection to the IO-Link master, the BET automatically detects the connected devices and enables simple parameterization. Both approaches offer reliable solutions for optimizing your IO-Link infrastructure.