5 facts about IO-Link

IO- Link saves time and money

Reading Time: minutes

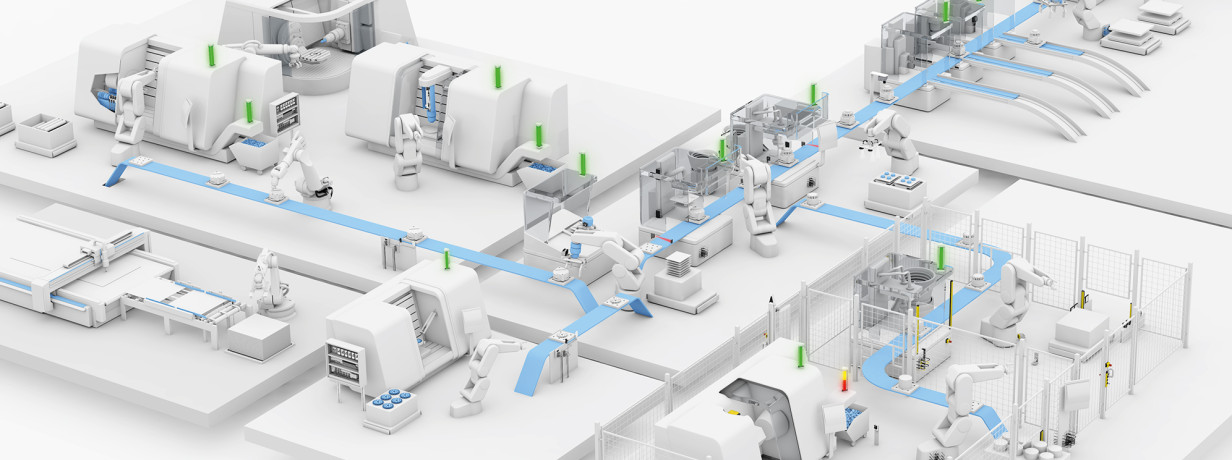

Balluff IO-Link ensures transparency for all of automation. In every area – whether logistics, service, production, assembly, inspection and packaging. And for every single application – whether fluids, identification, travel measurement or object detection.

At Balluff you get holistic IO-Link solutions with high-performance IO-Link sensors and the best IO-Link network and connectivity. Balluff speaks IO-Link in every field and with all principles of operation, so you have access to these IO-Link advantages throughout the entire system.

Universality

IO-Link is an open and manufacturer-independent communication protocol used in industry, enabling communication between sensors/actuators and PLC (Programmable Logic Controller) controllers. It is supported by various industrial device manufacturers, allowing for integration of different sensors, actuators, and other devices within one system.

Digital point-to-point communication

Digital point-to-point communication

IO-Link enables digital communication between devices and controllers, eliminating noise and signal interference typical of analog interfaces.

Bidirectional communication

Unlike traditional interfaces, IO-Link allows bidirectional communication. This means that devices not only send information about their status but can also receive commands and configurations from the controller.

Remote diagnostics and configuration

IO-Link enables remote diagnostics and configuration of devices. Operators can monitor device status, diagnose issues, and make configuration changes directly from the operator panel.

Increased flexibility and efficiency

With the ability to quickly change configurations and diagnose problems, IO-Link contributes to increased production flexibility and minimized machine downtime, leading to overall improved efficiency and profitability of industrial processes.

IO-Link provides a high standardization factor

IO-Link is the first globally standardized IO technology (IEC 61131-9) that communicates from the controller down to the lowest automation level. This universally applicable interface is a fieldbus-neutral point-to-point connection which uses standard unshielded cables. IO-Link sends all the sensor and actuator signals to the controller and in turn carries controller data to the sensor/actuator level with revolutionary consequences.

Easy installation

For IO-Link all you need is an industry standard 3- or 4-conductor cable. The uniform standard interface can be quickly and easily integrated into the fieldbus world to simply link even complex devices. One special feature: the digital communication ensures noise immunity even without the use of expensive shielded cabling. Analog signals are digitized with no conversion losses.

Highest machine availability

IO-Link enables quick, error-free sensor replacement and prompt commissioning. You can significantly reduce downtimes since the parameters of a replaced IO-Link sensor are automatically written from the IO-Link master to the new sensor. Commissioning processes, format changes or recipe changes are handled centrally via the controller’s function modules. This saves time and reduces the potential for mistakes to a minimum. Another advantage to you: IO-Link devices cannot be mixed up, since they are automatically identifiable via IO-Link. Requirements-based maintenance Continuous diagnostic data for the entire process extends your service intervals, since automatic readjustment via IO-Link means you need to maintain equipment and machines much less often. And now predictive error detection is even possible because the complete process parameters are consistently displayed in the controller.

Highest machine availability

IO-Link enables quick, error-free sensor replacement and prompt commissioning. You can significantly reduce downtimes since the parameters of a replaced IO-Link sensor are automatically written from the IO-Link master to the new sensor. Commissioning processes, format changes or recipe changes are handled centrally via the controller’s function modules. This saves time and reduces the potential for mistakes to a minimum. Another advantage to you: IO-Link devices cannot be mixed up, since they are automatically identifiable via IO-Link. Requirements-based maintenance Continuous diagnostic data for the entire process extends your service intervals, since automatic readjustment via IO-Link means you need to maintain equipment and machines much less often. And now predictive error detection is even possible because the complete process parameters are consistently displayed in the controller.

More efficient operation

With IO-Link you can position sensors in the machine just as the process requires, since accessibility of the sensors is no longer a factor. Process monitoring, configuration and error analysis of the IO-Link devices now takes place in the controller. Machine sequences are now time-optimized. Signal delays and distortions are reliably eliminated because digital transmission of data also ensures high signal quality. A wide range of application requirements can be easily met with IO-Link because you can use both binary and analog standard devices at the same time along with IO-Link sensors/actuators.

High-performance, consistent network

Controller concepts using IO-Link provide you with simple and universal solutions for a high-performance, consistent network, so that with this universal interface you profit from lower costs and are more flexible than ever. Use the typical applications presented on the next pages to learn about the possibilities IO-Link opens up for you.

Author

Balluff EMEA

We are your partner for innovative solutions in industrial automation. With our passion we improve your competitive position with speed and results. With our 100 years company history and more than 60 years of sensor experience, Balluff is a world leader and one of the most efficient manufacturers of sensor technology.

30 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.