Reducing Packaging Waste with Balluff 3D cameras

Intelligent 3D image processing – flexible, precise and without additional software

Reading Time: minutes

The EU has adopted new measures to reduce packaging waste (New EU rules to reduce, reuse and recycle packaging | News | European Parliament) and there is a general desire to reduce the size and amount of packaging where possible – for example, the UK’s Extended Producer Responsibility (EPR) sets a list of fees for packaging producers based on the weight of materials used. This blog post shows how a Balluff rc_visard 3D smart camera can be used as part of a package optimisation system.

The EU’s provisional rules for 2030 include the need to keep the ‘maximum empty space ratio’ below 50%. For dynamic packaging systems, where the contents change, this means that the fill-level must be monitored. For the UK’s system, minimising packaging minimises the fees.

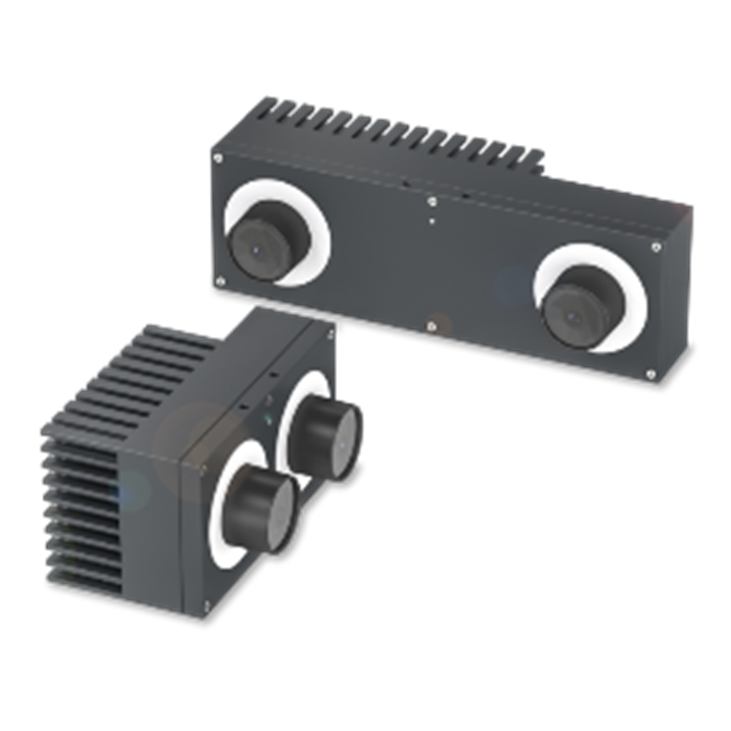

Balluff smart 3D camera

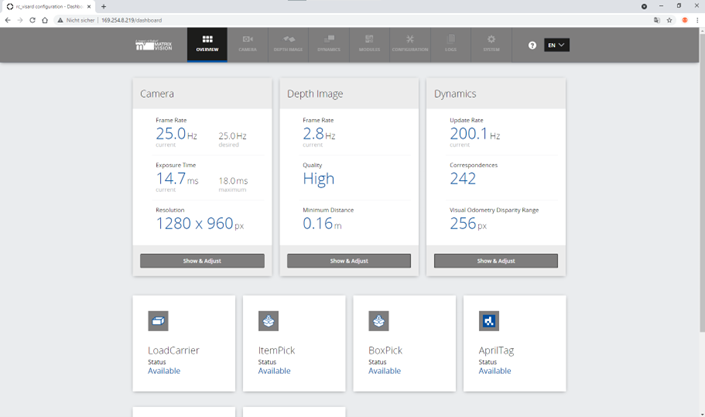

Balluff’s industrial smart 3d camera family have processing on-board to help with this requirement, as well as a choice of baseline, optics and colour or mono options to deal with different situations. As this is a smart 3D camera, all of the processing happens on-board and we can configure using a web-GUI without installing any software.

Balluff Web-GUI for 3D cameras

The system uses a pair of images to create depth perception, just like a pair of eyes. This is calibrated to real-world units and allows various 3D imaging applications including robot guidance and 3D measurement. The processing on-board allows pick-and-place or in this case fill-level applications to be realised.

Balluff Smart 3D camera family with 65mm and 160mm baseline size.

Optimised fill-level applications with smart 3D cameras

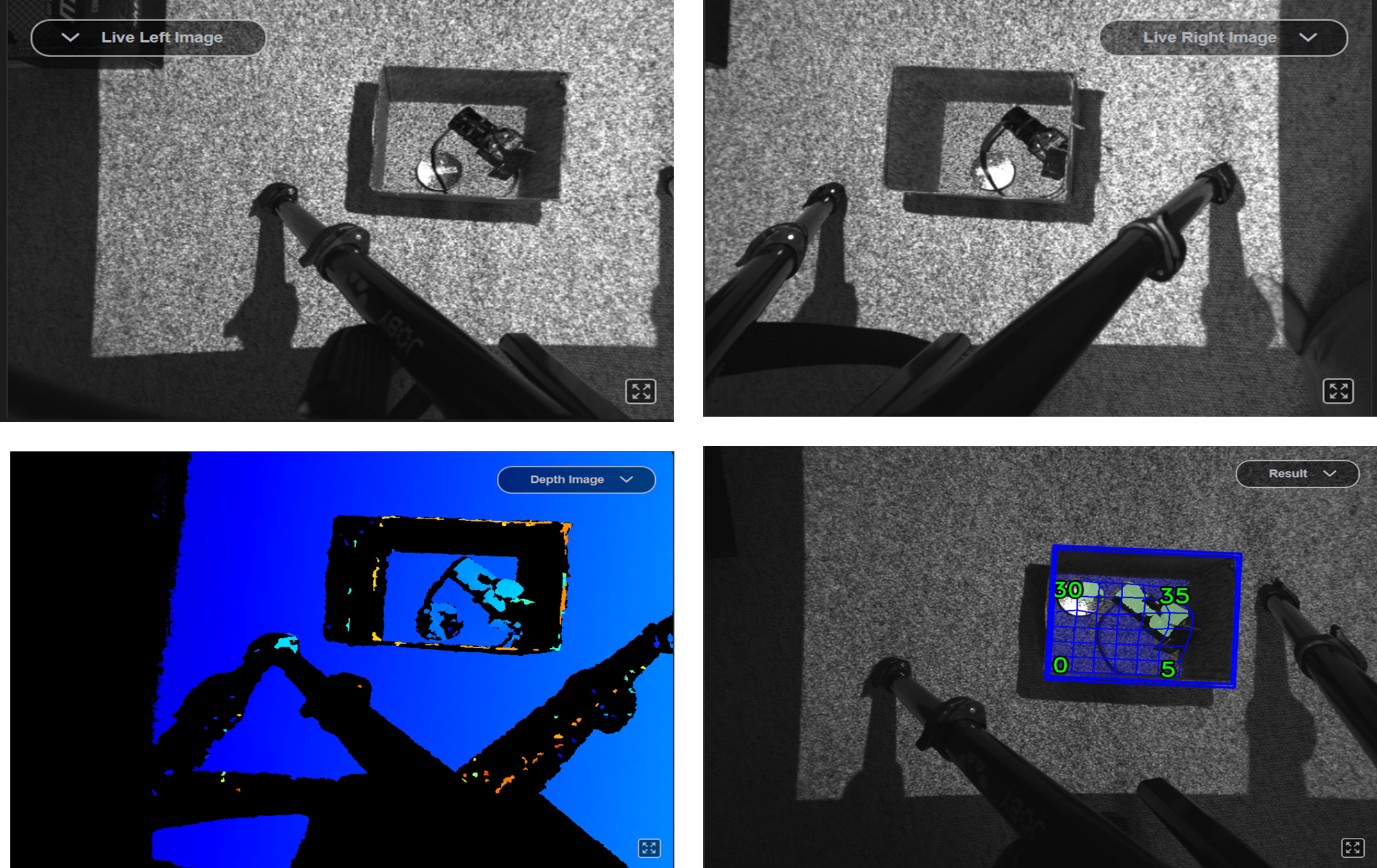

If we want to optimise the height of a carboard box, to allow it to be cut to the lowest height, we need to find the box and measure the height of the items inside.

The first step is to find the box and we can choose to divide the box into cells (maybe it has divisions, like a wine box) or look at the whole box and return the maximum fill-level.

To automate this process, we send a request to the 3D camera and get the response of the minimum, maximum and mean fill-levels. For the simple case, that’s all that’s required:

- Define the incoming cardboard box size (length, width and height)

- Trigger the camera with a request for the fill-level information

- Cut the box to the required height

In the real-world, things can be more complicated, so how do we deal with flexible boxes, image artefacts, reflective products and varying contrast?

Bright and Dark Products in the Same Image

One of the major differences between our eyes and machine vision cameras is how they respond to differing brightness levels: human eyes have a logarithmic response to brightness levels, whereas machine vision cameras have an almost linear response to light. This means that we can deal with vastly different brightness levels, whereas the cameras usually work on a small range. The images below show an image optimised for the bright products, but the dark objects are not picked up well:

We can change some camera settings to help, for example gamma can reduce the contrast and gain can increase the brightness:

It is an improvement, but in this case, camera settings alone aren’t enough. Now that we have reduced the contrast with the gamma settings in the camera, we can add extra light – a diffuse light to bring the general brightness level up and successfully find the black and bright products in the box:

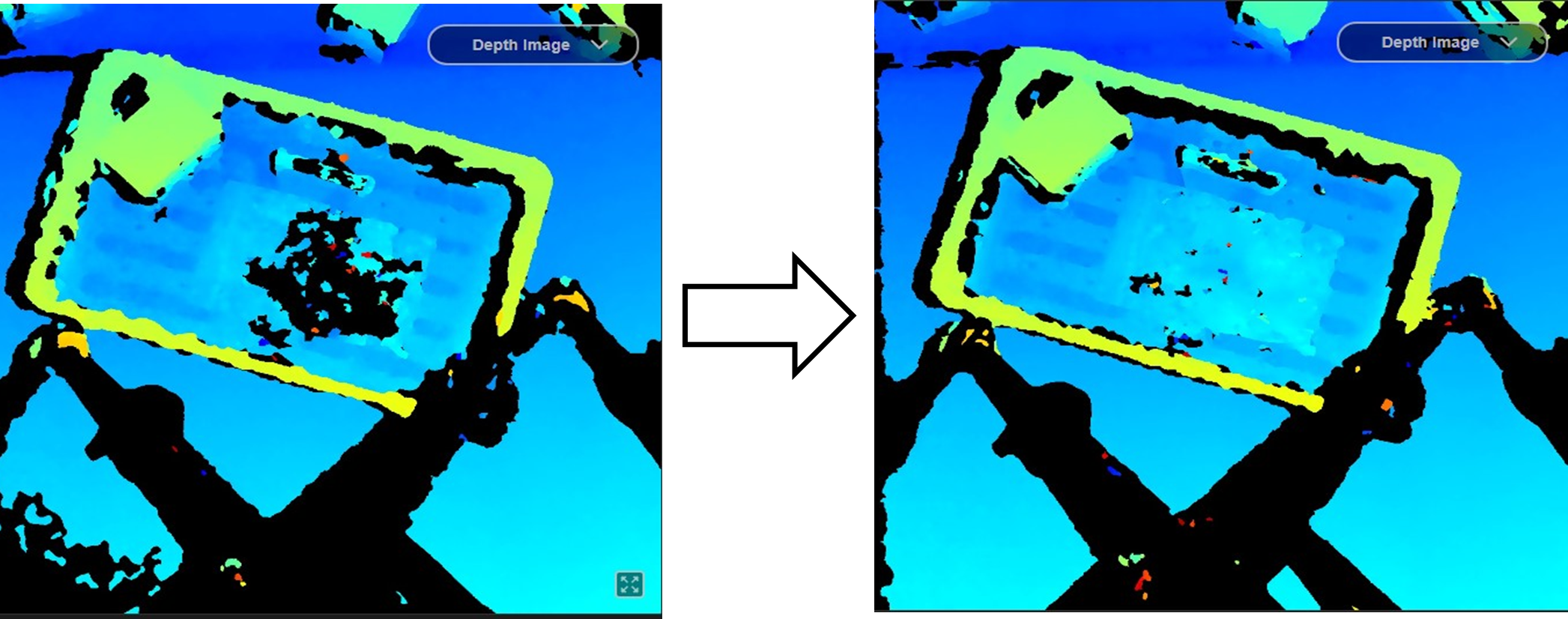

Dealing with Reflective Materials

Direct reflections can disturb the accuracy of the stereo calculations, imagine the difficulty of perceiving the distance to a mirror. But there are effective ways to deal with reflective materials – sophisticated lighting methods or polarising filters. Cross-polarisation is a method of using polarising filters on the light and on the camera lenses, if these are oriented 90 degrees apart, direct reflections are blocked but diffuse reflections are allowed into the camera. The depth images below show a tray with a mix of non-reflective items and a plastic bag that gives direct reflections. The left image is without cross-polarisation, the right image is with polarisation:

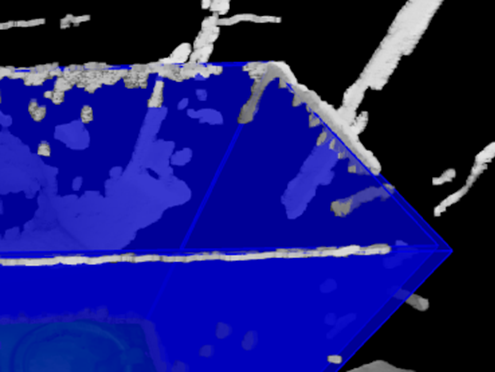

Flexible Cardboard Boxes

In most cases, boxes are made to be as thin as possible, to reduce the weight and cost of packaging materials. Until the box is sealed, this makes it flexible and there may also be an overlap where the carboard is glued to form the box. So, a box may not be a perfect cuboid:

We can add a small buffer of 5mm around the box to account for overlaps and flexibility:

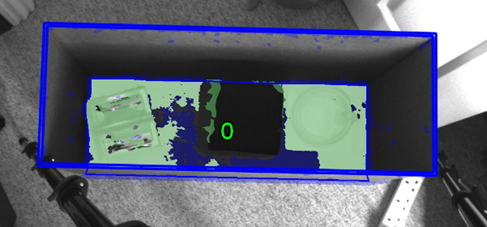

Removing Image Artefacts

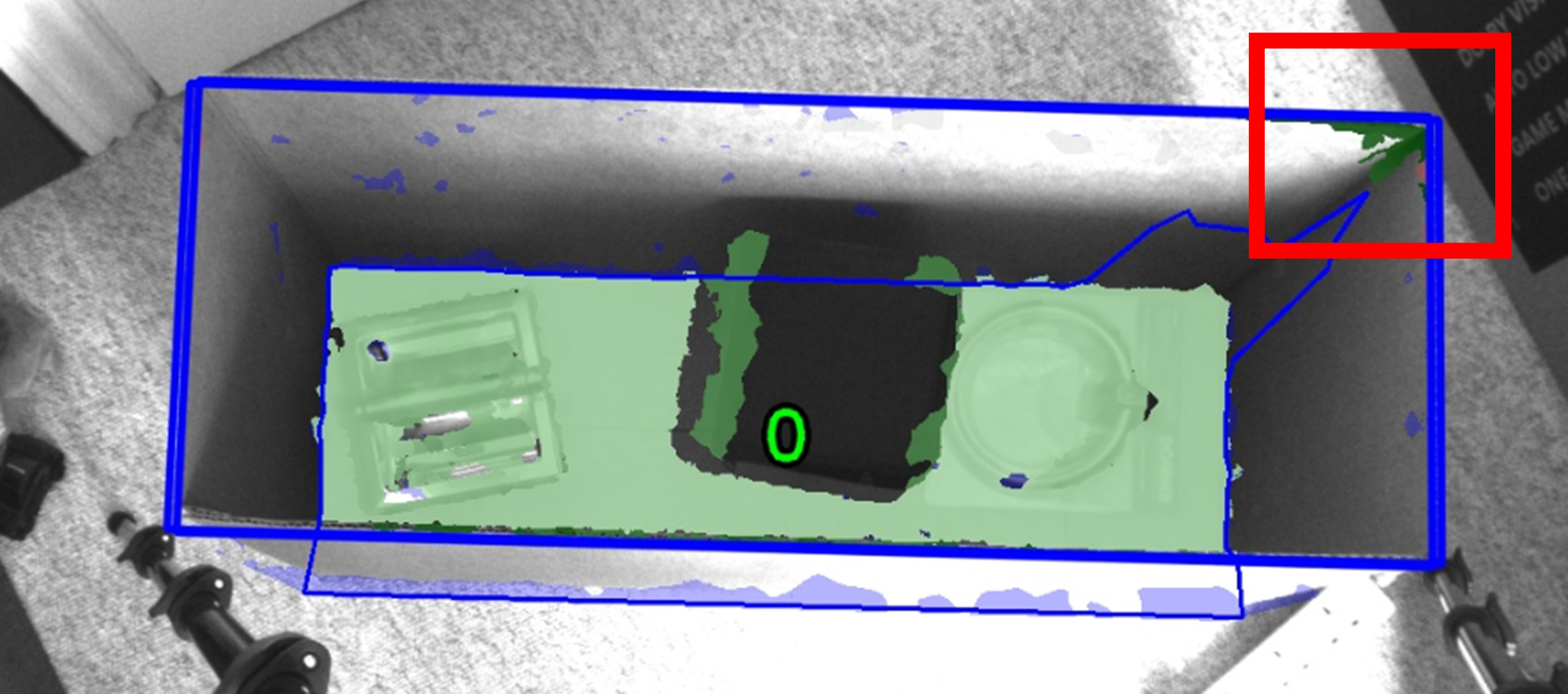

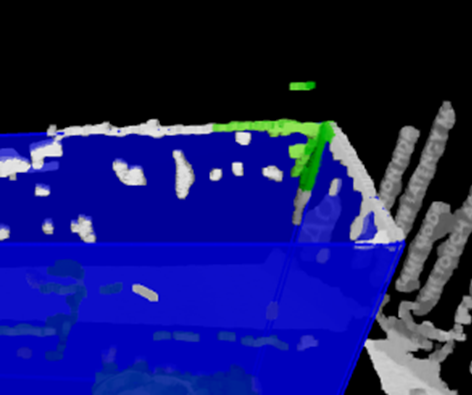

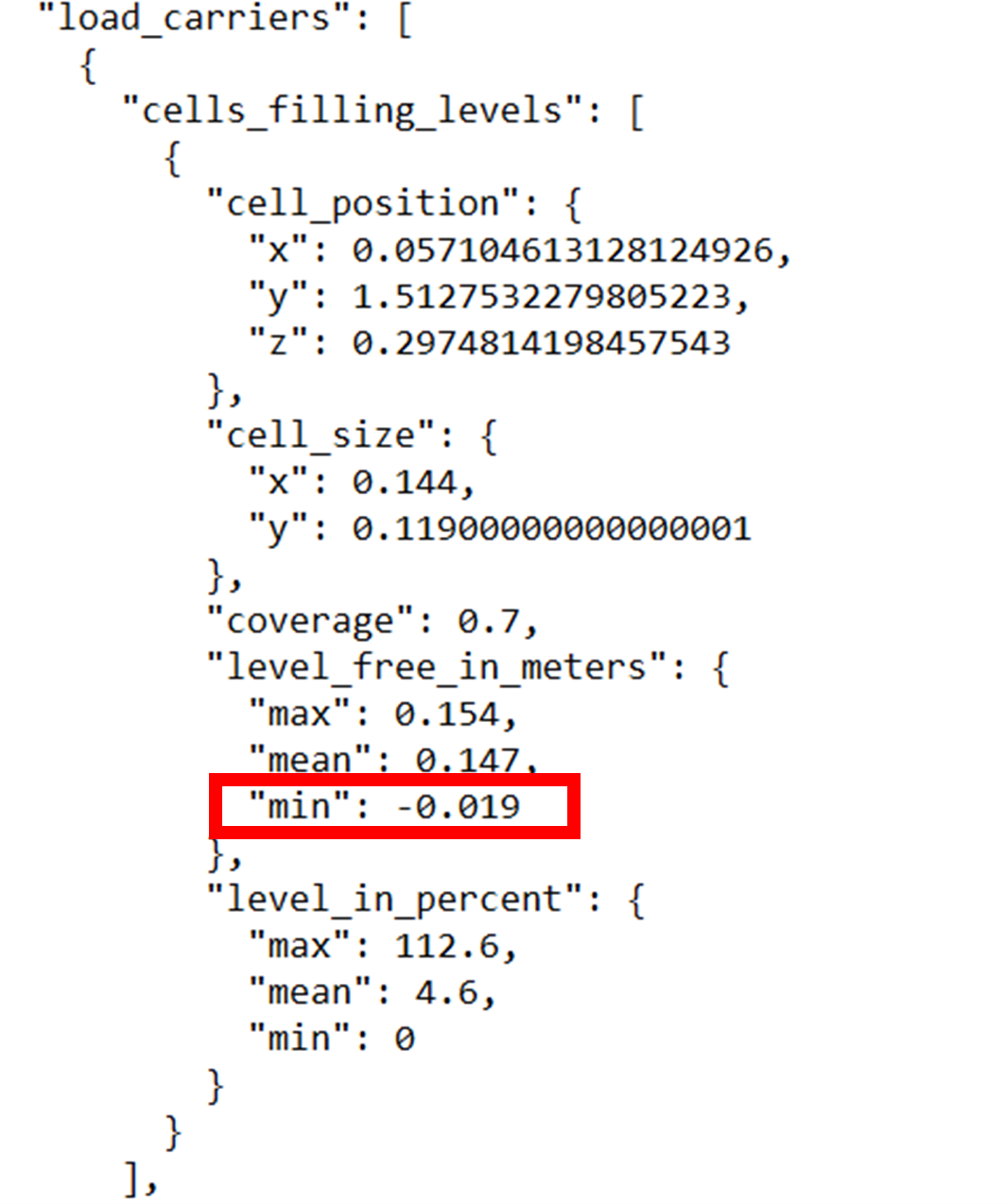

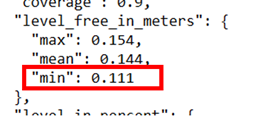

The response below shows the level free in metres (how far below the top of the box is the highest item). The ‘min’ level free in metres shows a negative value: maybe something really is higher than the top of the box, or maybe it is an image artefact.

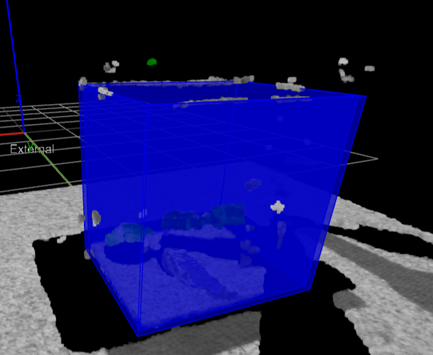

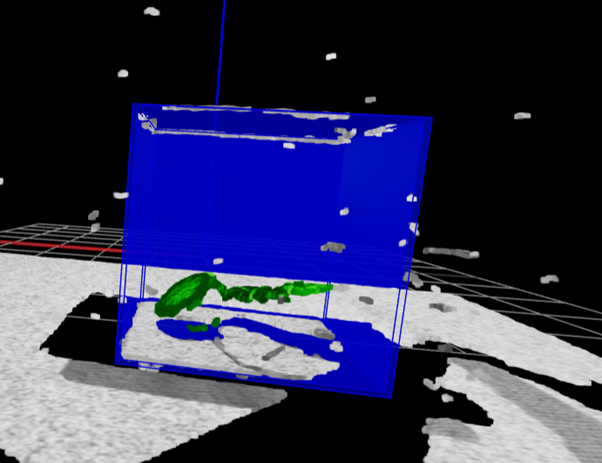

Looking at the 3D image we can see it is an image artefact: a small blob in space, not related to a real item (shown in green below).

Conclusion

Generally stereo systems are less affected by illumination effects than other systems, but this example shows that it is still worth applying the same principles to a 3D system as you would to any other machine vision system:

- Illumination: optimise the image before any processing

- Filtering: remove disturbing factors

- Pre-processing: prepare the images by removing unwanted artefacts

- Processing: when the above steps are followed, the processing becomes straightforward.

Save on all current smart 3D cameras

Balluff’s smart 3D camera allows applications like this to be carried out quickly and easily, with all processing on-board to give an efficient, secure method to stay within the packaging regulations. Find out more about our 3D camera portfolio --> Smart 3D Camera | Balluff

Author

Balluff EMEA

We are your partner for innovative solutions in industrial automation. With our passion we improve your competitive position with speed and results. With our 100 years company history and more than 60 years of sensor experience, Balluff is a world leader and one of the most efficient manufacturers of sensor technology.

30 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.