Unlocking Efficiency with Balluff's BCM Sensor: A Comprehensive Solution for Condition Monitoring

Learn from SOPEM's Success and the Versatility of BCM Sensors

Reading Time: minutes

Another proposal: Condition Monitoring

Recently, there has been a lot of talk about condition monitoring – the constant, continuous control, monitoring of actuators that are used on production lines. A good example of such a solution is the BCM sensor, i.e. Balluff Condition Monitoring Sensor, which in a small, compact housing has vibration measurement in three axes, temperature measurement, relative humidity and ambient pressure. As the example of our company – SOPEM – shows, the possibilities of how this sensor can be used even more broadly.

SOPEM, located in Niepołomice, is a production base of SOMFY – a world leader in the production of engines for gates, roller blinds, shutters and for controlling these devices. The Niepolomice branch is not only a manufacturing company, but also a logistics centre for Eastern Europe and an R&D department. Currently, about 600 people work in Niepołomice and they are mainly engaged in the production of engines for external blinds and roller shutters as well as remote controls for these devices.

Our challenge, which we decided to tackle at SOPEM and which led us to look for a suitable sensor, was the need to improve the noise control process for external blinds engines.

Process flow

Noise control is performed by operators who place the engine in a noise cabin and then rely on their senses and attention to qualify the engine as good (OK) or not (NOT OK). A manufacturing hall is an area where a lot of noise is generated, so sometimes this task is quite difficult. So we decided to find an alternative to the subjective evaluation of engines by the operator.

Our first idea was the so-called vibration analysis. To make it, we tested various sensors that, in addition to having the right functionality, also had to be compatible with industrial systems. The sensor that met our expectations, due to its easy integration process and simple way of connecting to a PLC or HMI to collect data, was the BCM.

The perfect solution

The BCM sensor (Balluff Condition Monitoring Sensor) fitted our needs perfectly, because in addition to the features mentioned above, it is also compact, which is a definite advantage. After renting the sensor, we were able to test it right away by building an offline position. Based on some profiles, we installed a 4-port master. Thanks to the functionality and versatility of the IO-Link interface, we easily integrated it into the machine by determining the data archiving algorithm – which process data would be used. There are really a lot of them and it would take us quite a while just to check all the capabilities of the BCM sensor. Łukasz Ostrowski from Balluff helped us a lot in the process.

The next step was to implement the IO-link master in the existing Profinet network. Then after finding the right algorithm, we plugged the BCM into the right port. With a dedicated magnetic attachment to the sensor, we were able to test the machine at various locations on how these vibrations would be collected. Currently, we are still looking for a suitable algorithm to collect the data.

Type of data used

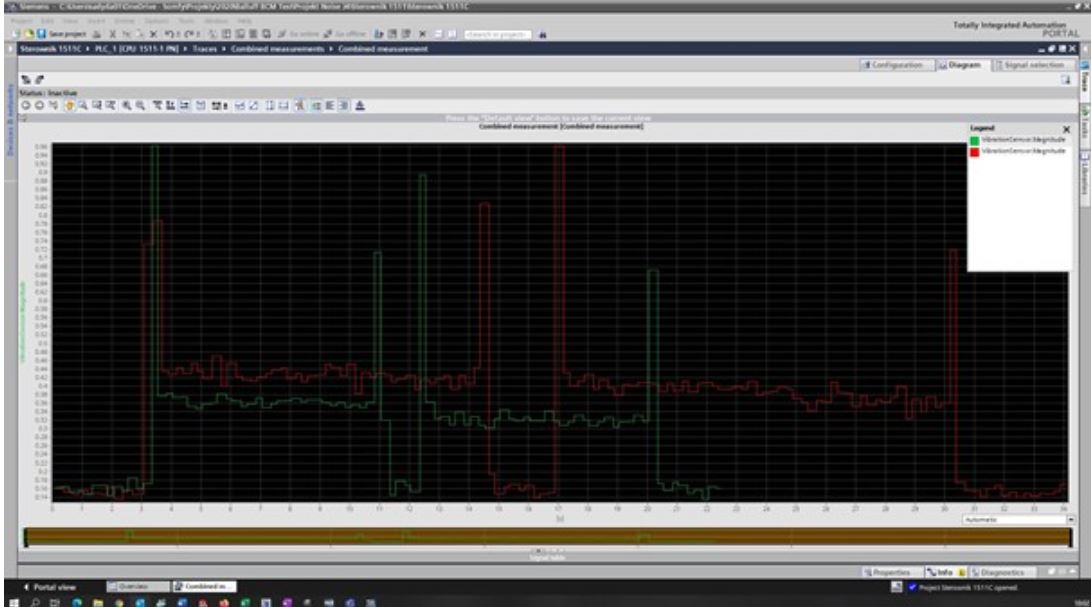

Using the BCM sensor, we primarily use two process parameters, namely VELOCITY RMS MAGNITUDE and ACCELERATION RMS MAGNITUDE. We collect this data with two motor movements because the operator who puts it on the machine starts the process with a button and makes an upward movement. We collect 30 measurement points from such a movement. When the engine then starts to spin down, we also take measurements. We compute the arithmetic mean from them to catch the appropriate level of vibration generated by the sensor and the standard deviation. During the testing phase, we noticed that the vibration level didn’t quite qualify the art as “NOT OK”. Sometimes it also happens that the oscillations are of an unusual character.

What has been achieved

At the moment we are collecting all the sensor data. We compare them with the data we receive from the quality department. They show that there were a certain number of “NOT OK” engines for a given day, and we compare that with the data we get from the sensor. We detect at least 95% of these errors. We also detect other types of errors, so it may be that we will detect many more such engines once the BCM sensor is introduced and implemented. If the solution is 100% accepted, we will copy it to the other machines. We would also like to look into position automation, where the engine is started automatically and only the data taken from the sensor will tell if the engine is an “OK” or “NOT OK” piece.

Keywords

- Case Study

- Innovations

- Sensors

Author

Balluff EMEA

We are your partner for innovative solutions in industrial automation. With our passion we improve your competitive position with speed and results. With our 100 years company history and more than 60 years of sensor experience, Balluff is a world leader and one of the most efficient manufacturers of sensor technology.

30 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.