The switch to intelligent hydraulics

How to reduce the risks of jumping into the IIoT

Reading Time: minutes

In the search for higher returns through increased efficiency and productivity, companies are gradually turning to the Industrial Internet of Things (IIoT), including in the field of hydraulics. But what are the reasons for this change?

One of the main reasons is to reduce energy consumption. Digitized hydraulics can also reduce material wear and reduce the amount of oil used, making systems cleaner and more environmentally friendly. However, some of the most significant benefits lie in condition-based or predictive maintenance to reduce downtime, based on precise condition monitoring and analysis.

With smart sensors, process transparency is achieved, providing analysis capabilities that we could only dream of two decades ago. Manufacturers and operators can now perform continuous monitoring to collect and analyze real-time data and diagnose and visualize conditions. This leads to higher plant availability.

This approach achieves a higher level of efficiency than preventive maintenance, which is carried out on a time-based (e.g. every six months) or usage-based (e.g. after a certain number of cylinder strokes) basis. Data-driven diagnostics can be carried out remotely. For remote or hard-to-access systems, this can save significant costs and increase employee safety by reducing the time spent traveling to diagnose malfunctions in difficult working conditions.

But is there an easy entry point? Many existing plants lack the technical requirements for condition monitoring. Retrofitting systems often fails due to the high effort and associated costs for the permanent monitoring of relevant machine and process parameters.

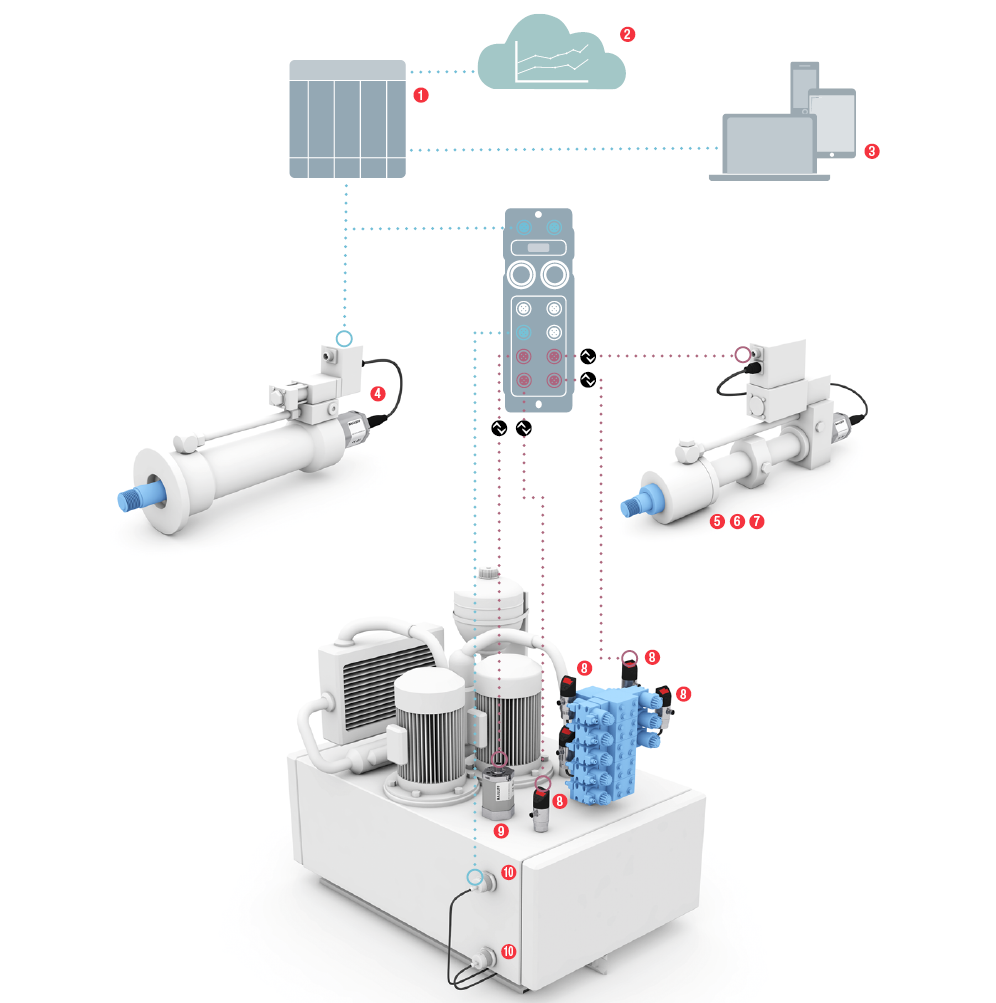

This is where the Balluff Condition Monitoring Toolkit (CMTK) offers a new and easy-to-implement solution:

Comprehensive retrofit solution for machine and process monitoring

High flexibility by connecting up to any four IO-Link sensors

Plug-and-play commissioning of the system and visualization of the data

Sensor setup wizard for simple configuration

Output of warning messages when adjustable limit values are exceeded

Autonomous system with data storage - independent of the cloud and machine control system

Remote monitoring from any location thanks to network integration

.jpg)

The toolkit consists of the Base unit (hardware) with integrated software for the automated collection and evaluation of sensor data. Balluff provides you with a wide range of IO-Link sensors to record this sensor data.

And all this with an excellent cost-benefit ratio. With the flexible CMTK, you quickly gain a deeper insight into the actual status of your machines and systems and can therefore detect deviations and problems at an early stage. All components are perfectly coordinated. High acquisition costs without added value are a thing of the past, because the CMTK is a complete system without hidden costs or complicated subscription models.

Further information and support can be found here 👇

Keywords

- CMTK

- Condition Monitoring

- IO-Link

Author

Manfred Münzl

Active in industrial sensor & automation technology for over 30 years.

1 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.