On the way to intelligent hydraulics with IIoT connection

From hydraulic system to digital drive solution

Reading Time: minutes

About a decade ago, the world was first confronted with the concept of Industry 4.0 at the Hannover Messe trade fair. A year later, General Electric coined the term 'Industrial Internet'. Back then, these ideas were still visions. Today, we are witnessing an industrial revolution in which intelligent, digitally networked hydraulic solutions are also becoming a reality.

Industry 4.0 marks the fourth phase of the industrial revolution, characterized by the integration of cyber-physical systems into machines and plants. The previous phases included mechanization in the late 18th century, the introduction of the division of labour and new energy sources in the late 19th century and automation, which began in the late 1960s with the development of programmable logic controllers (PLCs).

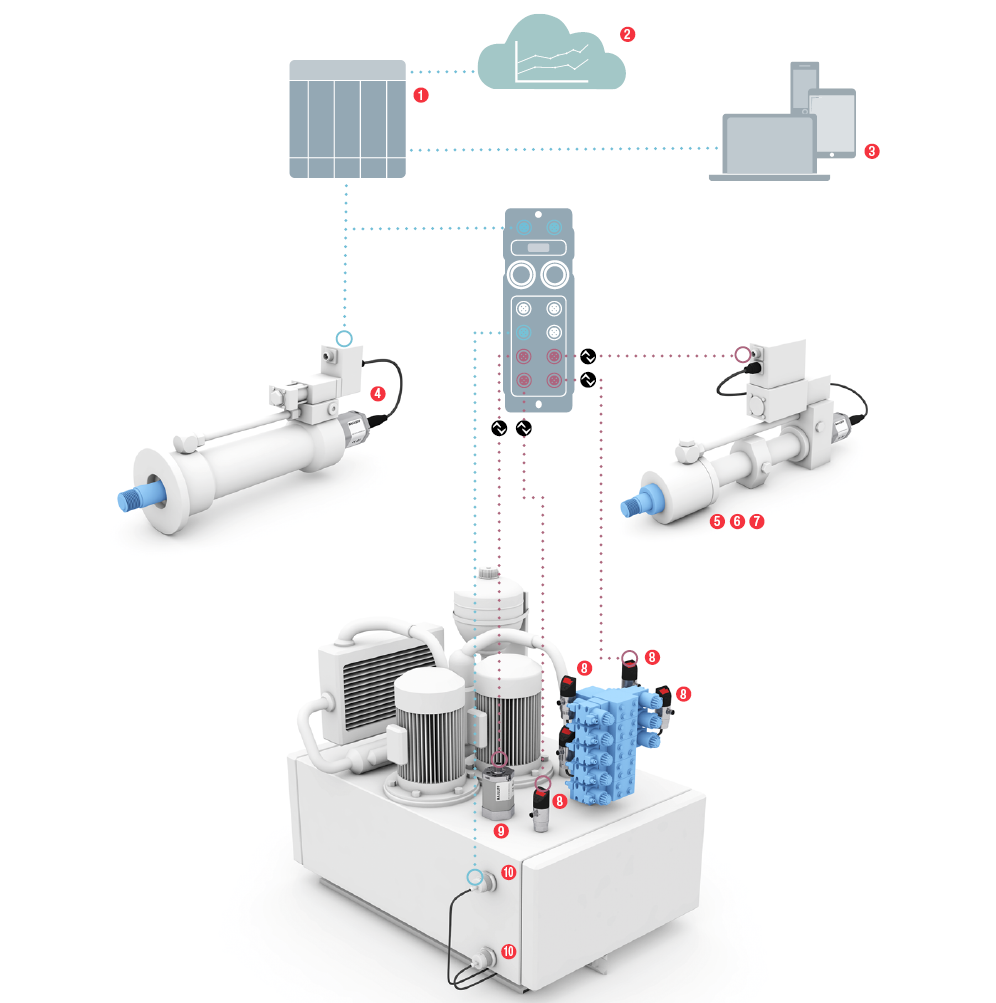

The Industrial Internet of Things (IIoT) is the catalyst that makes Industry 4.0 possible. It allows the integration of advanced sensors, digitized drives and other field devices to make processes more efficient. In fluid technology, for example, smart sensors are used to monitor various parameters in hydraulic systems such as temperature, pressure, flow, fill level and the stroke and position of actuators. These sensors provide real-time information about hydraulic processes and components that can be analysed and visualized to improve processes.

(1) Machine control (2) Analysis, data documentation in the cloud (3) Monitoring, Visualization of the recorded data (4) Autonomous axis in the field level (5) Recording the flow of fluid media with thermal flow monitors BFF (6) Temperature measurement with temperature sensors BFT (7) Valve parameterization via IO-Link (8) Pressure measurement with pressure sensors BSP (9) Continuous level detection with magnetostrictive position measuring systems BTL (10) Level control via level detection with capacitive sensors BCS

(1) Machine control (2) Analysis, data documentation in the cloud (3) Monitoring, Visualization of the recorded data (4) Autonomous axis in the field level (5) Recording the flow of fluid media with thermal flow monitors BFF (6) Temperature measurement with temperature sensors BFT (7) Valve parameterization via IO-Link (8) Pressure measurement with pressure sensors BSP (9) Continuous level detection with magnetostrictive position measuring systems BTL (10) Level control via level detection with capacitive sensors BCS

This is also facilitated, for example, by the IO-Link communication standard, which enables parameterization and communication from the field level via the control system to the cloud.

Today, intelligent hydraulics are used in a wide range of industries, processes and applications, from the iron and steel industry to stamping in the automotive sector and wind farms.

It remains exciting to see what innovations the next ten years will bring ...

Keywords

- Industrial Networking

- IO-Link

Author

Bernd Schneider

Engineer with many years of experience in plant engineering and automation technology

2 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.