Safety sensors and switches

Equipment safety using safety switches and safety sensors

Balluff safety switches and safety sensors are designed for a variety of applications. Our safe switches and sensors protect both workers and machine alike. The safety switches and sensors offer various operating principles: Inductive for non-contact safe detection of position and end-of-travel of metallic objects, electromechanical and Magnetic/REED or RFID-based for access or position verification for protection of personnel and machines.

Universal-use standard M12 cables save time and money during installation and assembly. They also help avoid wiring errors, gain clarity and ensure reliable monitoring.

Magnetic safety encoder systems

- Safe: Meets the requirements of DIN EN ISO 13849-1:2015 (Machine Directive, Pld), IEC 61508:2010 (Functional Safety, SIL2) and EN IEC 61800-5-2:2007 (Safety Function, SIL2)

- Saves time: Easy to set up with no configuration necessary

- Universal: Measuring lengths up to 48 m, selectable resolution, high system resolution to 20 µm

- Convenient: Configuration and diagnostics functions

Safety sensors and switches with RFID and Magnetic/REED Technology

Balluff Magnetic/REED safety switches ensure wear-free access protection at guard doors. When used with a spacing element, you can even install these magnetically coded safety switches in a ferromagnetic environment. And transponder-coded RFID safety sensors are the answer if greater vibration resistance and tamper resistance in guard door monitoring are required.

Electronic monitoring

Direct monitoring of robot work areas and end-of-travel of metallic tool holders in industrial environments can be accomplished electronically. This is simple to do using Balluff's non-contact, inductive safety sensors because unlike traditional safety switches or RFID safety sensors no special mating component is required, and these sensors are vibration resistant.

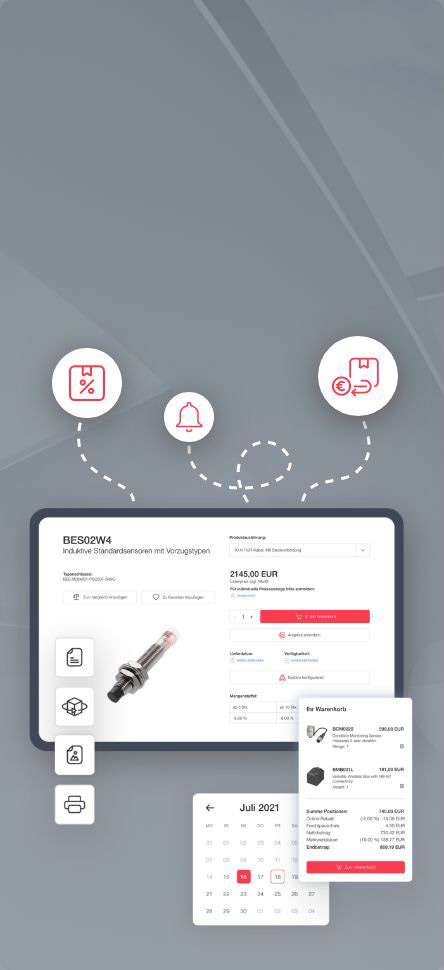

As is the case with all Balluff safety switches and sensors, the inductive safety sensors can be directly connected to the Safety over I/O module, which bundles all signals and forwards them via an IO-Link master module to the safety controller. As a bonus, you benefit from all the advantages of an intelligent Industry 4.0 solution.

The most important benefits

- Safety sensors and switches for a wide variety of applications

- Rugged housing versions with LED indicator

- Suitable for safety applications up to PLe/SIL3

- Savings of time and money plus prevention of errors due to standardized M12 connection technology

- Reduced installation expense and space requirements

- Also suitable for heavy protective equipment

- Tamper resistant

- Insensitive to vibration and imprecise door alignment

Products

Products