AI-supported image evaluation of multi-layer image files with the RadarImager from Balluff

Intelligently evaluate multi-layer image data with the RadarImager from Balluff

Reading Time: minutes

In modern industrial production, quality assurance is a decisive factor for the success of a product, because defective products can not only lead to financial losses, but also shake customer confidence and jeopardize the entire reputation of a company.

The RadarImager from Balluff is an innovative solution for quality control that is based on modern radar imaging technology and enables precise image evaluation. The use of the RadarImager in combination with intelligent image evaluation algorithms enables holistic industrial imaging solutions, especially if expertise in the field of image evaluation and vision systems is available.

The advantages of the RadarImager

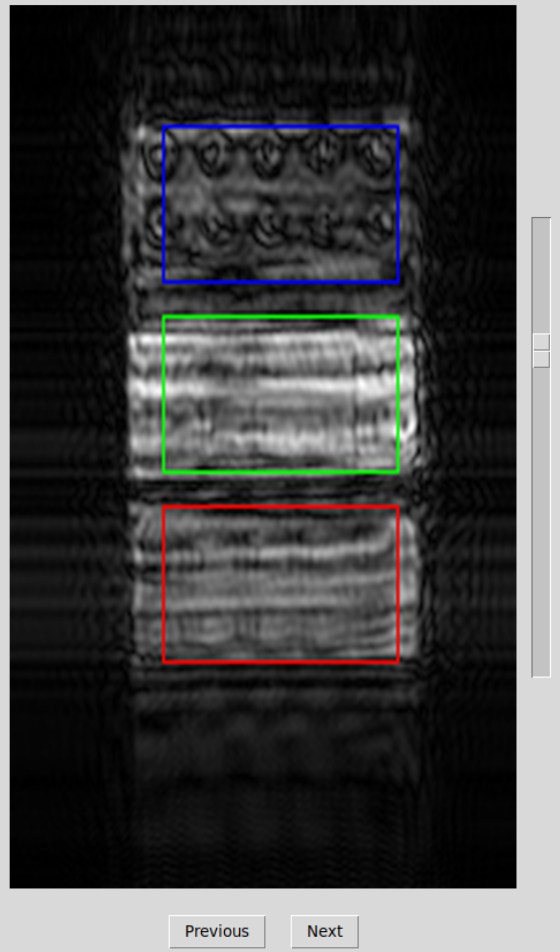

The RadarImager uses the advantages of radar technology to capture multi-layer image data, which is of great importance in industrial applications, as even materials that are visually opaque behave transparently. Unlike conventional imaging methods, which are often affected by environmental conditions such as lighting or dust, the RadarImager offers a robust solution that delivers reliable results even under difficult conditions. This is particularly effective and helpful in automation technology, where precise measurements and the detection of anomalies are crucial.

The output data generated by the RadarImager is not only visually clear, but also multidimensional. This opens up new possibilities for image analysis beyond the classic visual approach, especially when AI-supported approaches are considered. This is where the combination of classic image analysis approaches and modern deep learning (DL) algorithms comes into play.

Challenges and solutions in image analysis

However, processing multi-layered image data also presents challenges. One of the biggest hurdles is the complexity of the data, which requires efficient and precise analysis.

However, the fact that automation solutions already exist on the market is a major advantage. Classic image processing methods often reach their limits when it comes to recognising deeper patterns and correlations in the data. Here, a 2.5D or 3D DL algorithm or sequential data processing can offer a promising solution.

A 2.5D DL algorithm makes it possible to use the spatial information of multi-layered image data to gain deeper insights into the structure and properties of objects and can even process signatures whose potential was not recognised by the human eye from a visual perspective. By analysing image data in multiple dimensions, anomalies and sources of error can be identified more effectively. This not only leads to greater accuracy in quality assurance, but also to faster response times in error detection.

An even simpler approach: sequential data processing makes it possible to analyse multi-layer image data in a common context. This feature is already available in most image evaluation systems. By combining the analysis of image data, potential problems can be detected and rectified in the same amount of time as with moving camera images, thus directly preventing costly downtime.

Conclusion

The integration of AI into the image evaluation of multi-layer image data captured by Balluff's RadarImager represents a significant advance in industrial quality assurance. Despite the obvious challenges associated with processing complex data, modern approaches such as 2.5D or 3D DL algorithms and sequential data processing offer promising solutions. With the right expertise in image analysis and vision systems, companies can leverage the advantages of these technologies to optimise their processes and sustainably improve the quality of their products. The RadarImager is therefore not just a tool, but a key to a new era of industrial image processing.

Keywords

- RadarImager

Author

Balluff EMEA

We are your partner for innovative solutions in industrial automation. With our passion we improve your competitive position with speed and results. With our 100 years company history and more than 60 years of sensor experience, Balluff is a world leader and one of the most efficient manufacturers of sensor technology.

30 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.