- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Life Science

- Automation in the semiconductor industry

- Steel and Metallurgical Industry

- Fluid Power Technology

- Advancing battery manufacturing automation: achieving superior efficiency and quality

- Automobile industry and suppliers

- Mobile Equipment

- Drive Technology

- Metalworking

- Plastic Industry

- Intralogistics automation: improve efficiency and throughput

- Energy Production

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

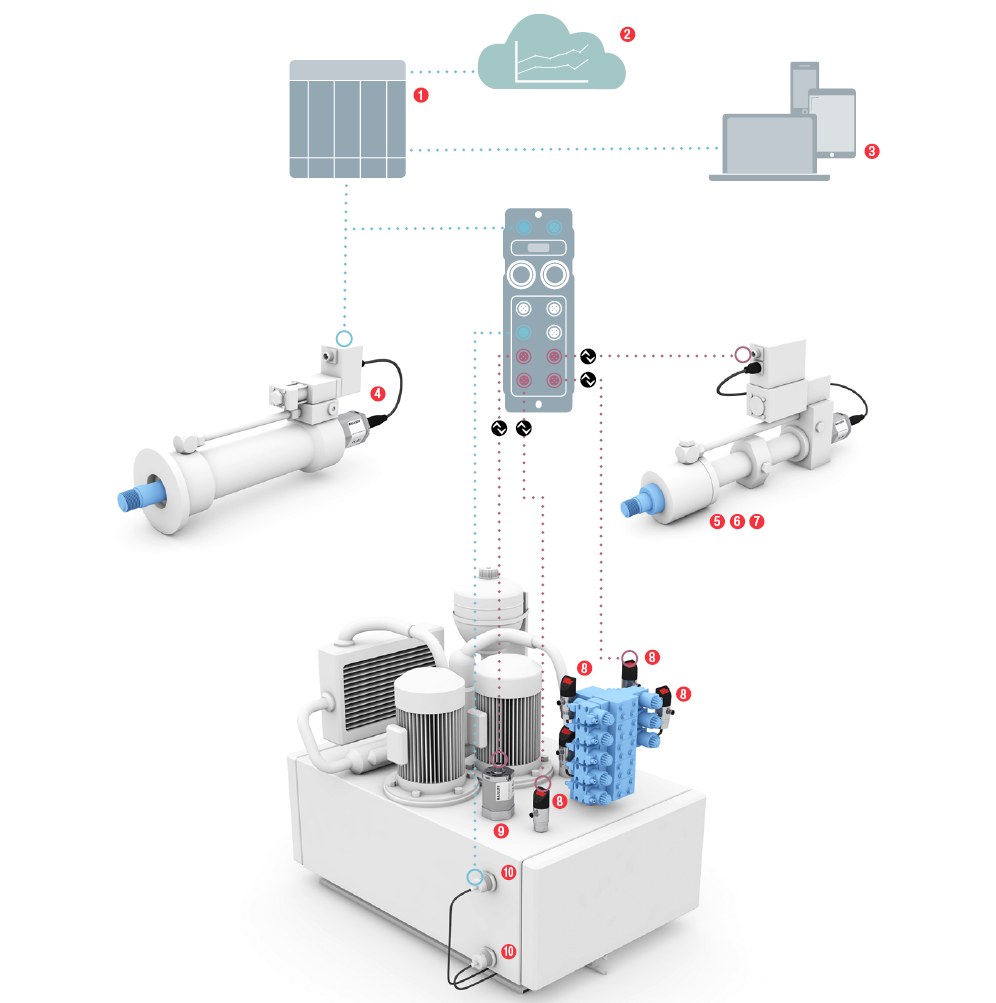

From the hydraulic system to the digital drive solution

Networked and highly flexible

Universal sensors and actuators handle any number of tasks and provide information and values in digital format using the standardized IO-Link protocol (IEC 61131-9). An IO-Link master communicates with the fieldbus level and the controller.

The values transmitted also provide information for diagnostics, can be documented and can be directly visualized or analyzed in the cloud.

This solution offers significant IO-Link advantages

Simple installation with pre-assembled standard cables

High level of economy thanks to cost effective unshielded standard cables

Noise-free signals over a digital interface

Ease of handling since the software for parameter setting and service data is manufacturer-neutral

Easy monitoring, analysis and documenting since individual service data are available

(1) Machine controller (2) Analysis, data documentation in the cloud (3) Monitoring, visualization of the acquired data (4) Autonomous axis in the field level (5) Detecting liquid media flow with BFF thermal flow controller (6) Temperature measurement with BFT temperature sensors (7) Valve parameterization via IO-Link (8) Pressure measurement with BSP pressure sensors (9) Continuous level detection BTL magnetostrictive linear position sensors (10) Level monitoring using limit value detection with BCS capacitive sensors

(1) Machine controller (2) Analysis, data documentation in the cloud (3) Monitoring, visualization of the acquired data (4) Autonomous axis in the field level (5) Detecting liquid media flow with BFF thermal flow controller (6) Temperature measurement with BFT temperature sensors (7) Valve parameterization via IO-Link (8) Pressure measurement with BSP pressure sensors (9) Continuous level detection BTL magnetostrictive linear position sensors (10) Level monitoring using limit value detection with BCS capacitive sensors

Products

Products