Modern packaging concept for chocolate bars

Case Study | Detecting format changes with RFID technology

Reading Time: minutes

The quality requirements of the world's largest premium chocolate manufacturers extend not only to raw materials and production processes, but also to product packaging. It is a necessity to receive perfectly packaged chocolate bars without any defects. Frequent changes in packaging format are a particular challenge.

Flexible machine for packaging in many different formats

Flexible machine for packaging in many different formats

LoeschPack has met this challenge in an exemplary manner, using the latest model of the LTM-DUO two-stage wrapping machine. The solution is based on the use of interchangeable parts for individual formats with a fixed stop. In addition, it is equipped with Balluff's proven radio frequency identification (RFID) system for automatic detection of interchangeable parts. The benefit for the user is reduced set-up time and increased flexibility in the format changeover process. Christoph Krombholz, marketing manager at LoeschPack, says:

This new solution was presented for the first time at Interpack in Düsseldorf, 2019.

The LTM-DUO two-stage wrapping machine was designed specifically for packaging chocolate bars.

The use of this high-tech equipment is recommended whenever a particularly flexible choice of packaging type, materials or size is needed, and with high productivity requirements. It offers excellent product quality, and the tightness of the packaging helps to effectively protect the products. This type of packaging also improves its appearance with its tight wrapping and elegant, flawless folding pattern. The system concept of completely separating the drive section from the product feeder section guarantees a high level of hygiene and good accessibility during operation, cleaning and maintenance.

The system is very versatile: using up to two packaging materials, different packaging methods can be achieved. Even the use of biopolymer packaging film is possible. With an operating speed of up to 215 plates/minute, the individual sequences of the LTM-DUO machine can only be seen when the speed is reduced for demonstration purposes. It is also astonishing how many complex steps and with how much precision the inner wrapping is performed at the first station and the outer wrapping in paper or cardboard of the entire package at the second station.

The LTM-DUO two-stage chocolate bar wrapping machine makes innovative packaging concepts possible

The LTM-DUO two-stage chocolate bar wrapping machine makes innovative packaging concepts possible

Precision drives

A special challenge is the variety of movements performed in the system, which must interact with each other at high operating speeds, requiring close coordination and precision of machine operations. LoeschPack relies on a combination of cam-controlled drives using a centrally lubricated main shaft and servo-driven movements, such as in the infeed conveyor. The centrally lubricated main shaft is equipped with hardened, machine-specific cams with specially calculated profiles that ensure coupling - positive drive and close coordination - of all movements and assemblies with the main drive, even at high speeds. "Their use is indispensable wherever many complex and identical movements are performed and high operational reliability is required for many years or decades. This is applicable to our equipment, since an average of 90 percent of the machines are destined for global export," notes Krombholz.

Complete format change in minutes

In order to get the most out of and obtain equipment with the greatest potential for modification, rapid format changes are essential. LoeschPack opted for fixed-stop format parts because they allow the machine to adapt to the use of new recipes, plate sizes and materials without the need for cumbersome manual changeovers and adjustments.

- notes Christoph Krombholz.

This virtually eliminates any deviation from the ideal setting caused by incorrect adjustment, which in turn can lead to packaging errors or even machine stoppage. The format parts delivered to the machine are usually already separated on the carriage. This makes it easier to see the situation and prevents mistakes, as the differences are often small and difficult to see with the naked eye. Short downtime helps increase productivity.

Automatic detection of interchangeable parts with RFID technology

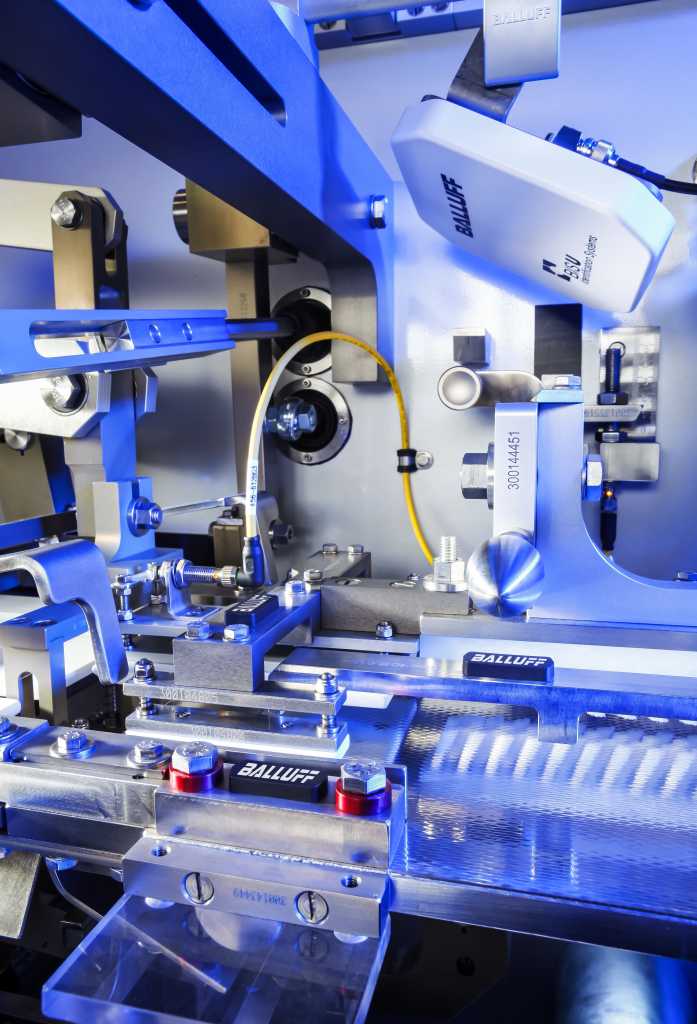

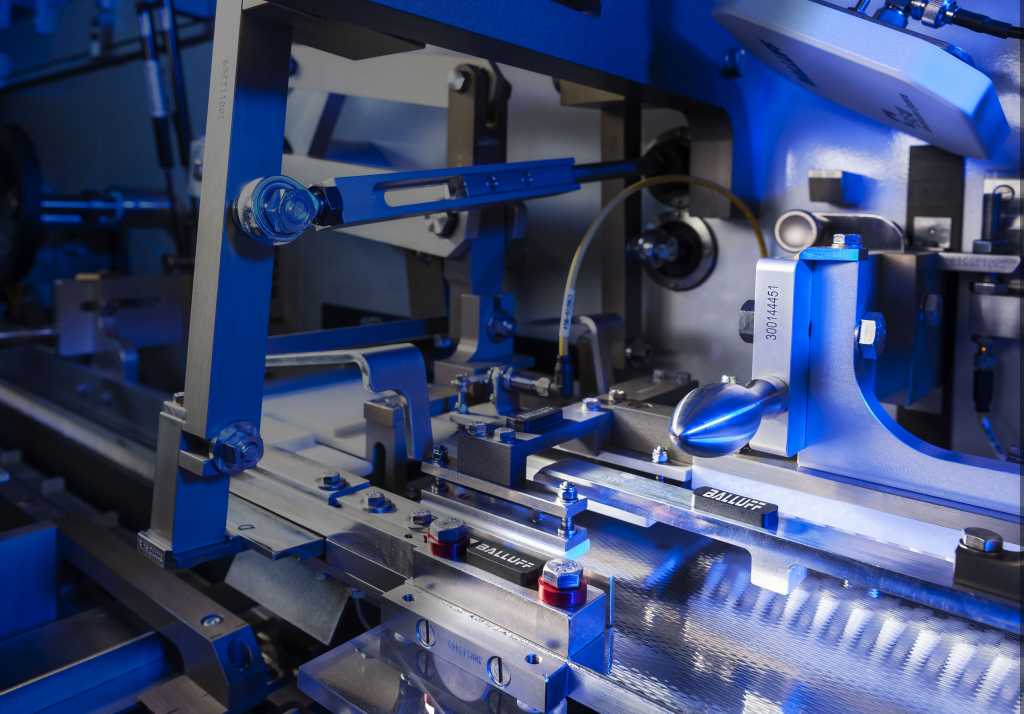

Balluff's BIS U industrial Ultra high-frequency RFID system provides automatic detection and identification of interchangeable parts. Instead of metal tags to identify parts, RFID data carriers are used. Their identification is carried out without contact, thus they are not subject to wear by the UHF read/write head.

- explains Christine Hanke, director of industrial affairs at Balluff.

All format parts are automatically detected and recognized with their identifiers

All format parts are automatically detected and recognized with their identifiers

The compact data carriers fit perfectly into the recesses of the format parts

The compact data carriers fit perfectly into the recesses of the format parts

The main components of the BIS U industrial RFID system are a processor, at least one UHF directional antenna with circular polarization, and the aforementioned transponders for object identification. The machine controller automatically analyzes the information and initiates the recorded actions accordingly, thus actively supporting the user. An LED beacon with an IO-Link interface, Balluff SmartLight, visualizes progress during exchanges by changing colors. It is visible even from a great distance. For this purpose, it has a wide range of colors with the possibility of freely selecting the intensity of the light. The system activates only after all the replacement parts have been placed and installed in the right place. This eliminates the possibility of damage to the machine caused by starting up with the wrong parts attached.

As with the Balluff level indicator, the SmartLight signaling column visualizes the progress of changeovers

As with the Balluff level indicator, the SmartLight signaling column visualizes the progress of changeovers

As Balluff's Christine Hanke notes, "The special feature of the SmartLight is that it can be flexibly adapted to virtually all possible controller requirements without the need for cumbersome hardware configuration. In this way, we got rid of the need for the usually cumbersome combination of modules with different colors to create a signal column." At the same time, connecting to the controller via the IO-Link-Master module provides many of the typical advantages of the IO-Link interface, such as plug-and-play installation and seamless commissioning with convenient parameter setting capabilities.

The Balluff UHF system can be easily integrated into the system design. The ultra-compact 7.1 x 3.1 x 13.1 mm data carriers are completely flat and can be attached to format elements so that they do not protrude above the surface. Since the serial numbers of the format parts, the so-called UID codes, are stored in memory, they can be uniquely identified at any time, even if the transponders are attached to metal surfaces. This was also one of LoeschPack's basic requirements.

The passive data carriers also do not require their own power supply, as they draw their energy from the UHF read/write head. This eliminates the need for batteries. The electronic components and antenna are built into the tag. Together with passive tags, the UHF solution offers a range of up to 6 meters and high wave capture reliability. The system is capable of mass wave capture, so that all interchangeable parts within the antenna range can be effectively read regardless of their spatial orientation. Another example of the use of this technology compared to traditional identification methods, such as barcodes, is the ability to load data (e.g., the service life of a part) into the label. This information can then be continuously updated, although this system does not yet use this functionality.

With Balluff's BIS U RFID system, the LTM-DUO machine is also properly equipped for worldwide use, as Balluff's RFID solution operates at frequencies from 860 to 920 MHz and meets global ISO 18000-6C and EPC Gen 2 Class 1 standards. In addition, the solution can be retrofitted into existing installations without much effort using a standard international interface.

The companyLoesch Verpackungstechnik GmbH- also known as "LoeschPack" - is a leading international manufacturer of packaging machines and complete packaging systems for chewing gum, chocolates and dry baked goods. This company, founded in 1919 and headquartered in Altendorf near the city of Bamberg, Germany, is today part of the Piepenbrock Group with 26,000 employees and a 90% export share. As a partner and systems supplier to the confectionery industry, the company offers comprehensive services worldwide. LoeschPack also provides its customers with support throughout the entire life cycle of the equipment - from conception to design, construction and commissioning - including training and the supply of spare parts.

Keywords

- Efficient production

- Case Study

- RFID

Author

Balluff Sp. z o.o.

We have been active on the Polish market for more than 25 years. We serve our customers from Pomerania to the Tatra Mountains, providing first-class service and technical support. We are also present online, where we share our knowledge about the latest implementations, industry trends, events or technical aspects of our solutions.

41 Contributions

Comment

Popular posts

What is a capacitive sensor?

How do I wire my 3-wire sensors?

Industrial sensing fundamentals – NPN vs PNP

The industrial revolution - from the steam engine to Industry 4.0

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff Limited

-

20 Cheshire Business Park

Cheshire Avenue

Lostock Gralam

Northwich, CW9 7UA