Asset Data Provider

Driving digital transformation through intelligent IIoT software

The industrial world is changing: more and more companies are turning to digitalization and automation to make their production more efficient, flexible and future-proof. The key to this lies in the Industrial Internet of Things (IIoT), which enables intelligent networking and communication between machines, plants, sensors, systems and the Cloud.

But despite the great potential, industrial companies repeatedly encounter challenges that make the successful implementation and operation of IIoT solutions difficult. With the Asset Data Provider, Balluff offers an integrative solution to overcome these challenges and accelerate digital transformation.

The top 3 IIoT challenges for industrial companies

1. Overcoming data heterogeneity in the OT landscape.

Ideally, plants and production facilities are newly built or modernized all at once so that IIoT-enabled machines are installed together. These have digital interfaces that can provide data. Often, industrial productions consist of a wide variety of existing machines that are not capable of outputting data.

In either case, a heterogeneous data landscape is created: access to data is difficult, the data is located in silos, there are different types of data as well as obsolete and diversified data types. In addition, the data originates across numerous sites, systems, and facilities.

Whether with a brownfield or greenfield approach, Balluff's Asset Data Provider is able to pull data from all of these assets, transform it, and make it available in IT systems in a compatible manner.

2. It's all about data quality

Digitization and automation projects are highly dependent on the quality of data. In the industrial environment, contextual data, also called metadata, is often lacking. For this reason, relevant data must first be obtained from raw data and transformed accordingly into usable information. Another obstacle here is that stand-alone data cannot be easily processed further and accordingly do not provide any added value. They must first be contextualized and linked to other data.

The solution? Our Asset Data Provider offers a common data model. It enables the central bundling, translation and processing of all data the Asset Data Provider is able to normalize and transform data and thus create a uniform data layer. It forms the basis for further efficient data analysis and processing.

3. Lack of know-how, high costs and lack of time

Digital transformation in industry is progressing only slowly. This is often due to high skill barriers, a lack of talent, internal resources as well as know-how. This poses a challenge to both IT and OT teams, which they encounter again and again in the digitization process. The result is difficult projects that drag on, incur high costs and make it difficult to calculate ROI.

With its low-code and drag-and-drop feature, the Asset Data Provider facilitates the development of complex integration projects. No extensive knowledge is required, so skill barriers, implementation time, and total cost of ownership (TCO) are significantly reduced.

The Asset Data Provider: Accelerate IIoT projects

With the Asset Data Provider, Balluff offers an integrative software-as-a-service (SaaS) solution to accelerate digitization projects. The Asset Data Provider is a software solution for the collection, pre-processing and provision of data to IIoT applications generated, for example, by industrial assets such as machines, plants and sensors at the OT level.

With the Asset Data Provider, Balluff offers an integrative software-as-a-service (SaaS) solution to accelerate digitization projects. The Asset Data Provider is a software solution for the collection, pre-processing and provision of data to IIoT applications generated, for example, by industrial assets such as machines, plants and sensors at the OT level.

Balluff goes one step further: in addition to data generation and transport with our products, we also enable data pre-processing at the edge level.

Asset Data Provider Cloud

Asset Data Provider Cloud offers a comprehensive selection of predefined modules for quick and easy creation of intelligent data flows using drag and drop functionality. Additional features such as one-click deployment, access rights, version control and a Credentials Vault extend functionality and enhance security.

Flow Studio:

Module library:

The Asset Data Provider library consists of the potential building blocks needed to build intelligent data flows. In addition to connectors, it also contains modules for analyses and data transformation and processing. It is continuously being expanded to generate the greatest possible customer benefit.

Drag and drop

The drag-and-drop function lets you select modules from the library and assemble them as you need them. This makes it easy for people without programming skills to create, test, and deploy data flows. It's easy to create your own data flows in minutes.

Test data flows

To test the functionality of data flows, you can use the so-called sandbox. Use this test environment to check the streams you have created. Alternatively, you can also validate them in a real environment.Flow templates

Templates can save you a lot of time in your daily work. Simply save a created data flow as a template and simplify the future conceptual design of flows.

Control Center:

Flow life-cycle management: Flow life-cycle management enables secure node deployment and simplifies one-click deployments and mass deployments of data flows. You save time and resources while achieving high security and efficiency in data management.

Enterprise management: Efficiently manage access rights, perform version control, and securely store sensitive credentials in the Credentials Vault. This ensures privacy, security and transparency for your data flows.

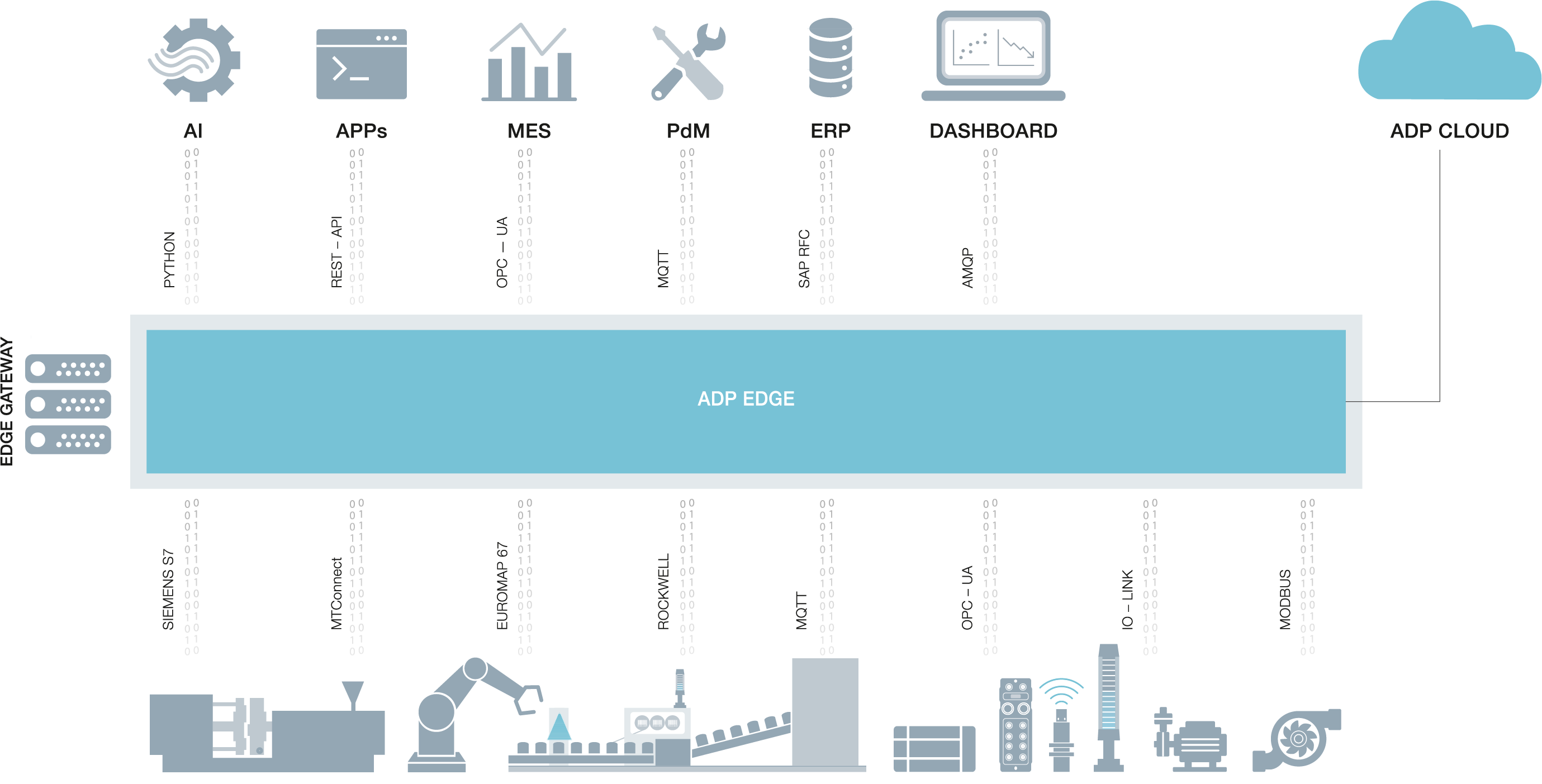

The Asset Data Provider Edge

Runtime for data flows

The Asset Data Provider Edge is a lightweight and powerful application. It serves as a runtime for your data pipeline, which you install as a Docker container on the Linux operating system. The Asset Data Provider Edge processes data available directly from the data source and real-time streaming analysis of up to 100,000 messages.

Deploy anywhere

There are a few reasons why hybrid infrastructure, rather than a complete move to the cloud, makes sense for many organizations. Among them are networking costs, data storage and processing costs, latency and security. The Asset Data Provider is centrally managed and can be seamlessly installed anywhere to access and process your data in a distributed hybrid architecture:

|

Cloud |

On-Premise |

Factory Floor |

Edge |

IO-Link configuration

The Asset Data Provider enables manufacturer-independent and central commissioning, configuration, and parameterization of IO-Link masters and devices according to the IO-Link standard for sensors and actuators.

The Asset Data Provider at a glance

|

Challenge |

Asset Data Provider |

Added value |

|

IT/OT teams face bottlenecks: High skills barriers, lack of talent, and slow pace of digitization. |

Low-code & drag-n-drop |

Agile development enables low barriers and easier development of integration workflows. |

|

Limited data access, encapsulated data, multiple data types, stale data, and distributed data across many sites, systems, and assets. |

Any data: streaming data, APIs, files. Any location: edge, on-premise, cloud. |

Integrate all data: Break through data silos with intelligent workflows for horizontal and vertical integrations. |

|

Poor data quality, no common data model, large volumes of raw data, and no actionable data. |

Advanced data transformation |

Non-experts are empowered and can innovate without depending on IT. |

|

Very high hurdle in terms of IT infrastructure, skills and DevOps to execute advanced logic. |

Hybrid-first: distributed edge nodes |

Future-proof infrastructure enables scalability. Any real-time and data workflow use case can be implemented. |

|

Insufficient centralized control over distributed teams, data and software. |

Centralized control and governance |

Centralized control reduces risk and increases efficiency for large rollouts. |

|

High cost, long term projects, difficult to calculate ROI. |

Intelligent data workflows including AI/ML |

Low TCO: Low cost of development and lifecycle changes, low IT workload, and lower cloud costs. |

License the Asset Data Provider

10 Connections |

25 Connections |

50 Connections |

100 Connections |

|---|---|---|---|

|

|

|

|

|

|

Monthly payment, one year duration |

Monthly payment, one year duration |

Monthly payment, one year duration |

Monthly payment, one year duration |

|

|

|

|

| Order now | Order now | Order now | Order now |

Use cases: Put IIoT readiness into practice.

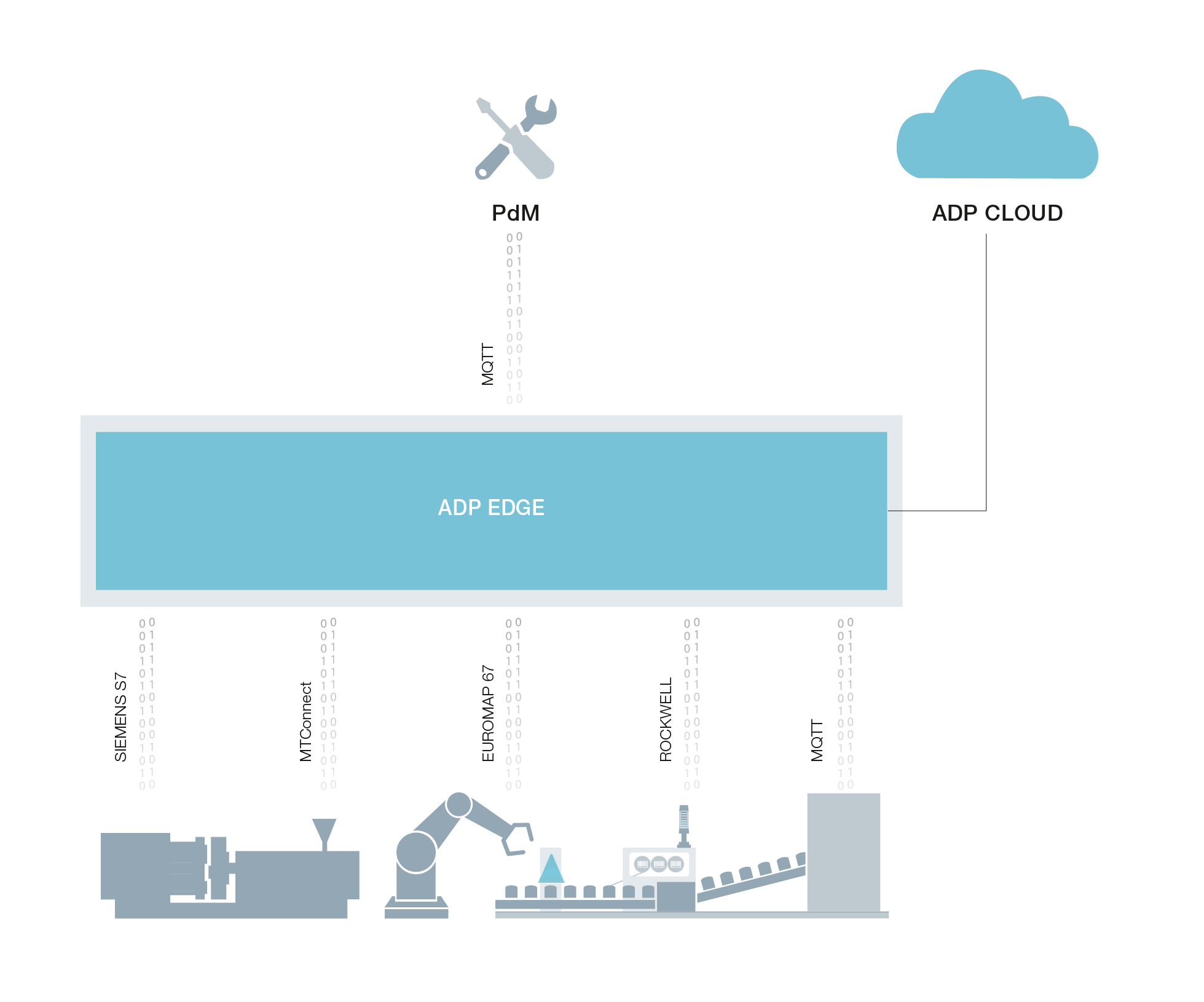

Predictive maintenance

To maintain or even improve quality standards and avoid downtime, the industry is increasingly looking to predictive machine maintenance. The prerequisite for this is an OT landscape networked with IT.

In this context, the still-common limited connectivity to OT equipment is a real showstopper. With smart software solutions like the Asset Data Provider that enable data transfer from OT to IT, you can feed the predictive maintenance system, also known as the PdM system, with the data collected from the production assets.

- Consistent E2E integration between OT and IT

- Overcome data silos

- Correct provision of data specific to the PdM system

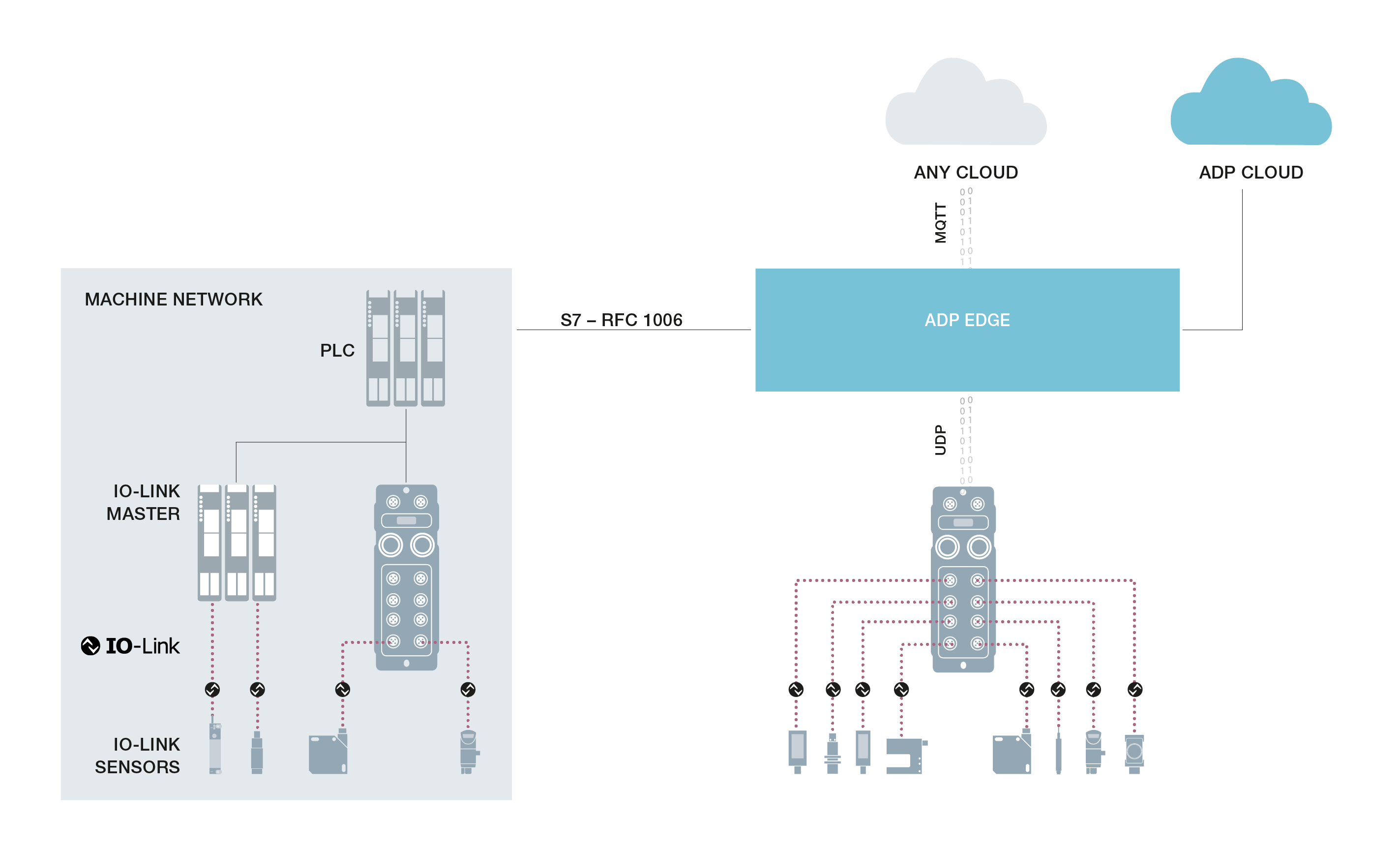

Retrofit any sensor to any cloud

A typical problem of Industry 4.0 is the mostly heterogeneous machine landscape. Often, no data can be extracted or the data formats are not compatible with existing systems. PLCs are often designed for the functional operation of the machine and not for data retrieval or provision by IT systems. For this reason, machines on factory floors often require cost-intensive retrofitting. A more cost-effective alternative is retrofitting with intelligent sensor technology such as IO-Link sensors. This is how assets become IIoT-ready quickly and efficiently.

The Asset Data Provider is able to translate, bundle and output all data extracted from any OT level sensors to all cloud systems.

- Easier and faster implementation of IO-Link sensors on the machine.

- Reduce the load on the PLC

- Make machines IIoT-enabled easily

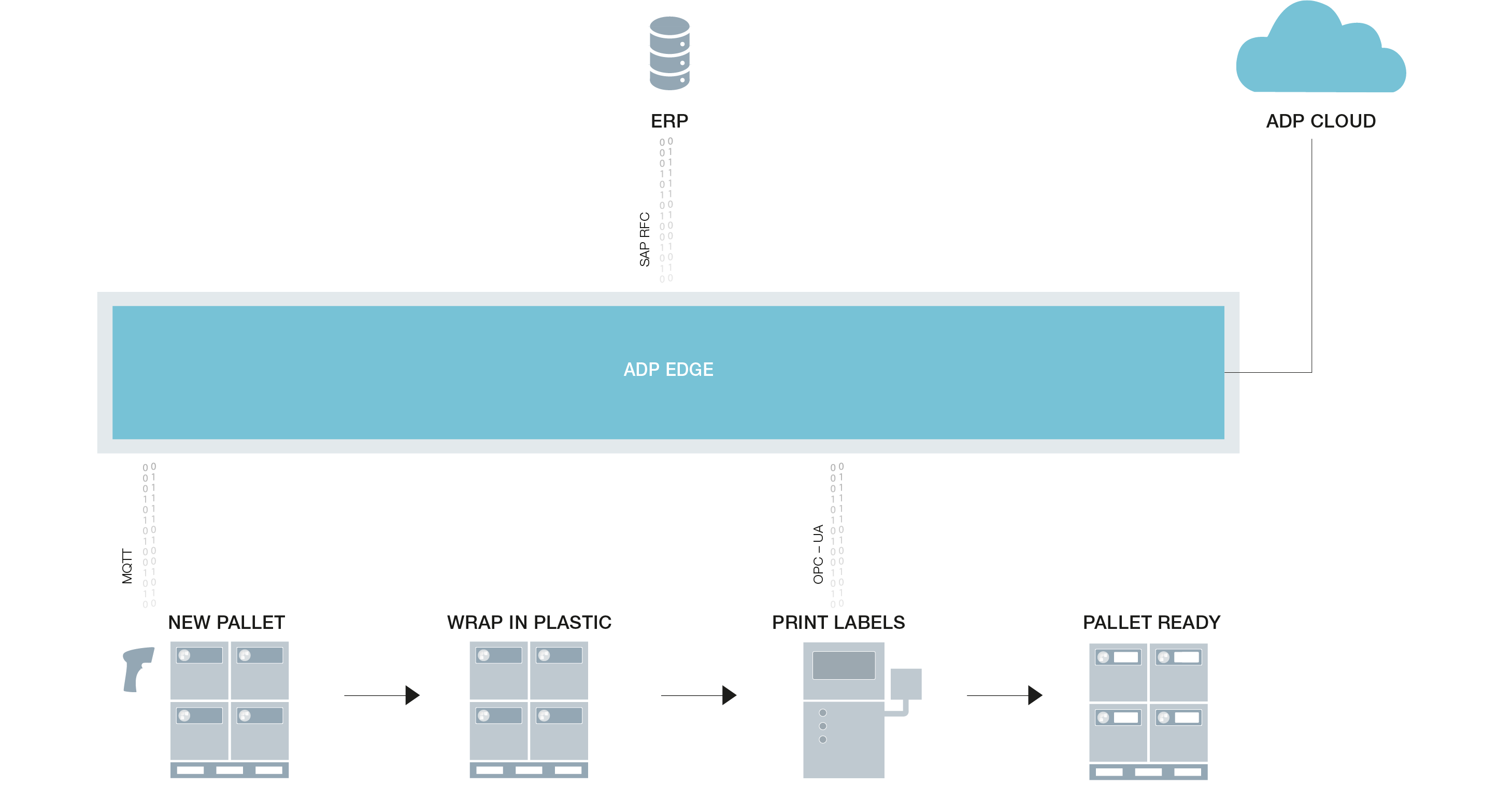

Integrate the ERP system into the machine landscape

Automating the packaging line by integrating the ERP system with the machines improves production performance. When a packaging task begins, the ERP system sends information to the machines. Once the product is ready, label information is retrieved from the ERP and sent to the printer. After the labels are printed and applied, the system reports task completion to the ERP. This automation of the process increases efficiency, reduces errors and improves the traceability of your products.

- Simplifies implementation by bypassing the automation stack

- Optimization of throughput by approximately 30%

- Creation of a closed loop between SAP Cloud and on-site logistics.

Do you need help?

Please contact us - we will be happy to support you!

Products

Products