For increased quality assurance: Making the invisible visible

Detection of hidden objects with radar technology

Quality assurance is a decisive factor for many companies. They are faced with the challenge of testing products efficiently, automatically and without damage to their quality. Manufacturing companies need to ensure product quality to achieve maximum output.

This is precisely where Balluff's RadarImager comes in. This industrial 3D imaging system - based on radar technology - screens a wide variety of packaging. It allows you to scan all kinds of "hidden objects" to make anomalies visible. With the RadarImager you can check packages for completeness, product integrity or identify foreign objects and take quality control to a new level.

The advantages of the RadarImager

- Help identify impurities

- Increase process reliability

- Save inspection machine length

- Reduce recall costs

The RadarImager in practice

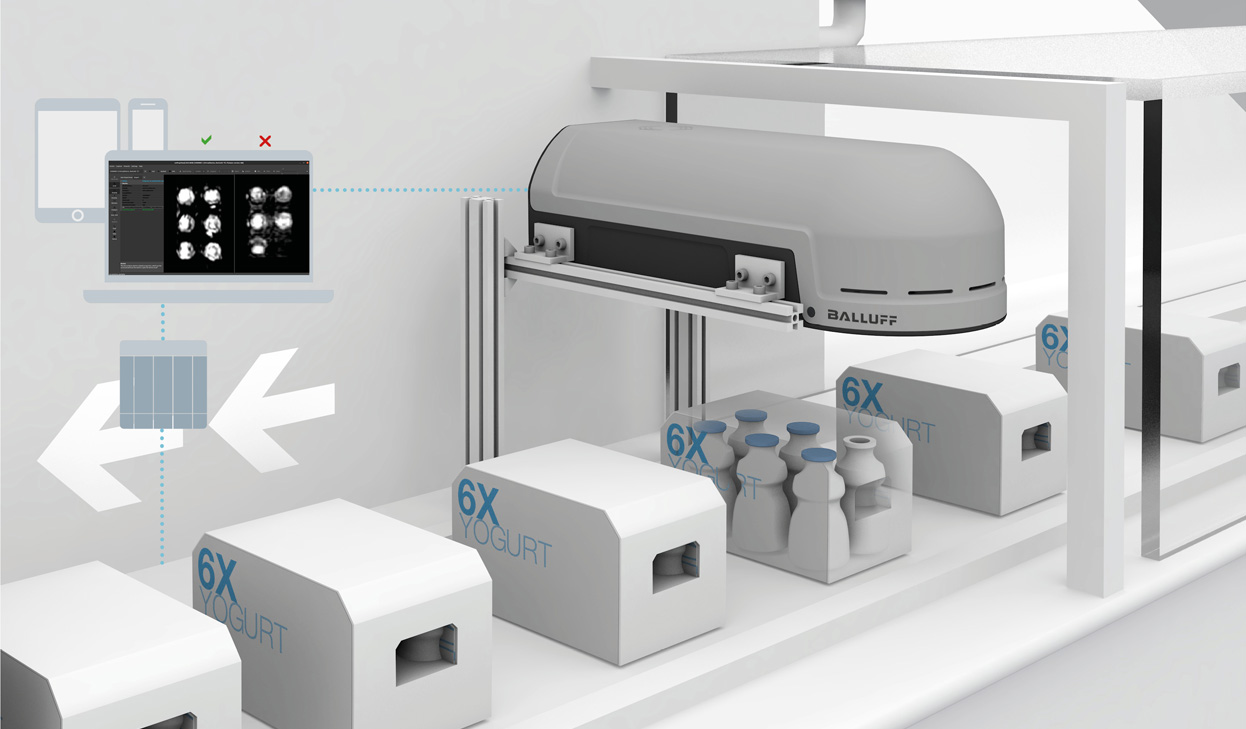

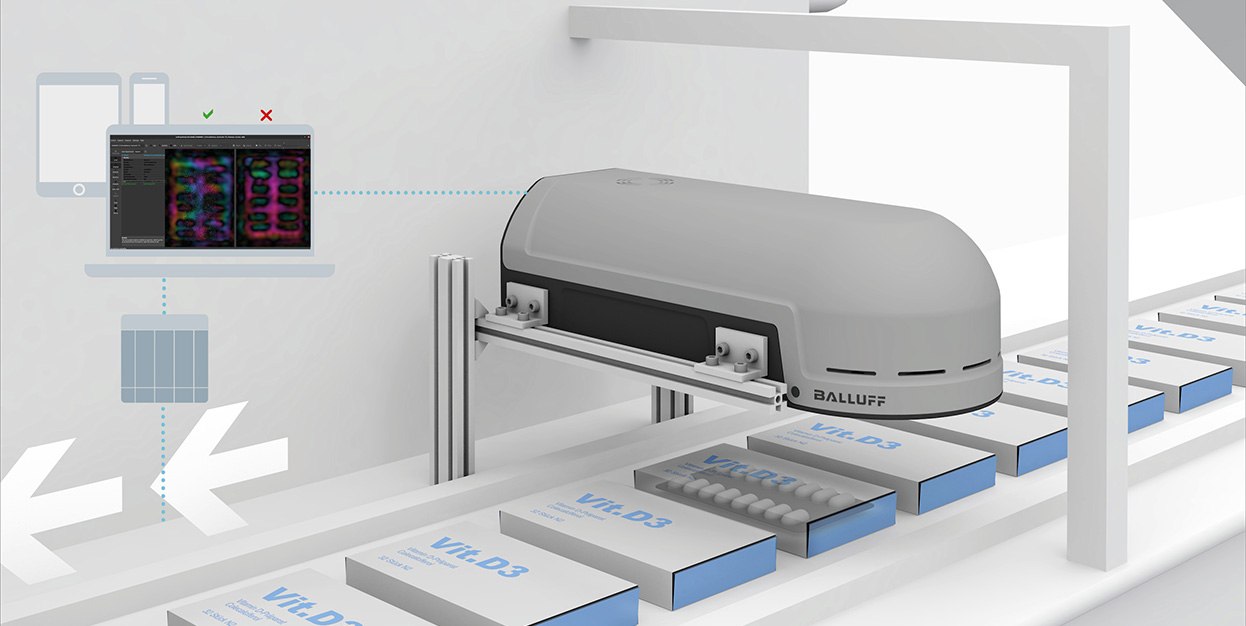

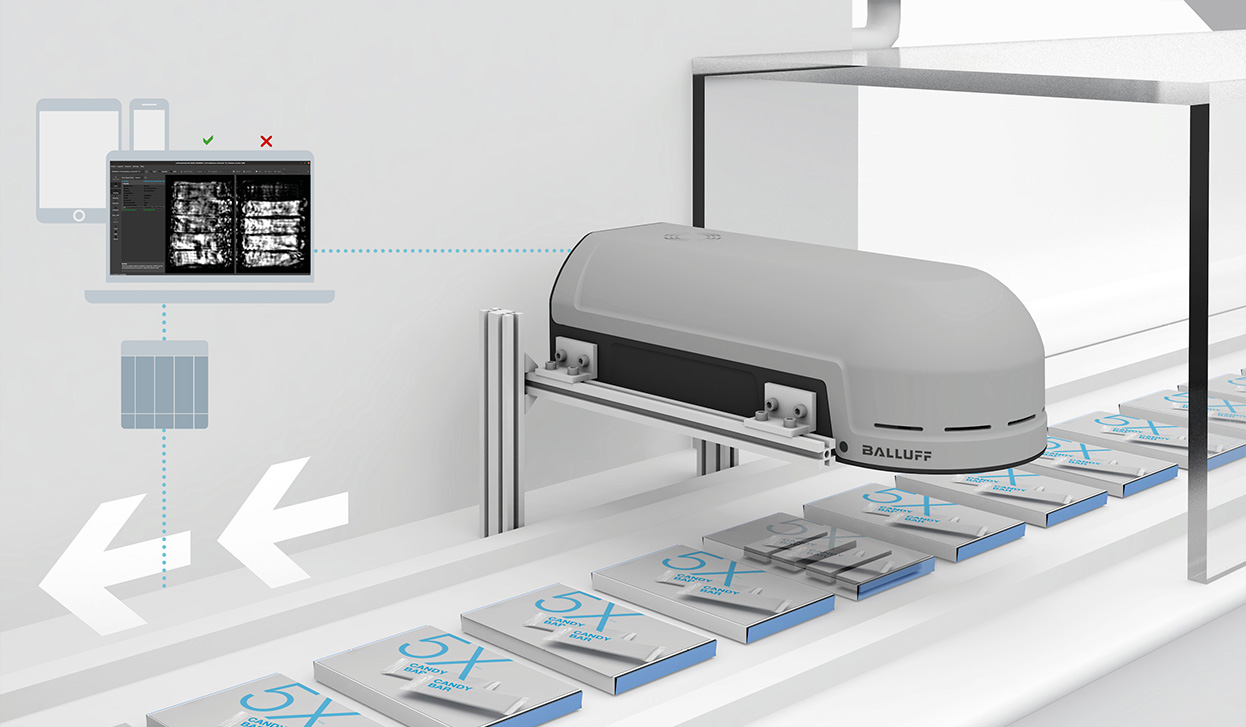

Whether for companies in the packaging, pharmaceutical or food and beverage industries, there are countless use cases for the RadarImager. This is a small selection of how you can ensure the quality of your products with the help of modern radar technology.

Application example in the food and beverage sector

There are many different types of packaging in the food and beverage sector. There is a correspondingly wide range of quality assurance applications in this sector.

Checking the contents of the packaging for completeness

Detecting impurities and foreign bodies

Checking packaging for integrity

Checking the closures

Detecting fill levels

Application example from the pharmaceutical industry

Quality assurance plays an absolutely central role, especially for medications, dietary supplements or other products from the pharmaceutical industry.

Checking for completeness of packaging incl. package insert

Checking packaging for integrity

Detecting impurities and foreign bodies

The RadarImager: Detect what is hidden

Imagine being able to easily scan the inside of products without damaging or affecting them, regardless of environmental conditions and without harmful radiation.

That's exactly what the RadarImager - an industrial 3D imaging system - makes possible. It is based on radar technology and is capable of scanning a wide variety of packaging materials. To do this, the RadarImager emits electromagnetic radar waves that are reflected in different ways, depending on the object. This "reflection data" is used by software to create a series of images, a so-called image stack, which can be used for evaluation and contribute to increased quality assurance.

The RadarImager represents an alternative to currently used technologies and, it opens up completely new possibilities for solving applications in the field of quality control. Where today complex measures are required to enable measurement, the use of the RadarImager offers a significant simplification. This also has a positive effect on the inspection machine length.

This is how your quality assurance benefits:

Inspection for completeness

Detection of impurities and foreign bodies

Detection of surface condition

Check for integrity of the packaging

Light independent

The RadarImager is able to scan all non-conductive materials such as foils, cardboard and plastics. Metal, conductive objects and liquids can be detected but not scanned. For example, metallic objects or particles can still be detected and fill levels checked.

In the RadarImager, a 3D image stack consisting of individual image layers is calculated from the recorded data. These layers are provided in the standard GenICam GenDC format. Transmission takes place via Gigabit Ethernet using the GenICam GenTL Producer Interface. The GigE Vision protocol is used for communication and data transfer. Subsequently, an evaluation can be performed with the calculated images. Either a single image or several images from one measurement - an image stack - are offered.

How does Radar Imaging work?

The term radar is short for "Radio Detection And Ranging." Using electromagnetic waves, a radar typically determines the distance to an object and its relative speed.

The electromagnetic waves are generated by a radar transmitter and radiated toward the target object, propagating at the speed of light. When the waves hit an object, they are reflected by it, scattered, and partially propagate back toward the receiving location, where they are received by the radar receiver. The received signals are then processed and analyzed in a signal processing unit. In modern low-power radar sensors, it is not uncommon for the transmitter, receiver and, in some cases, signal processing unit to be located together on just one chip, resulting in a very small footprint.

If the radar has several transmitter and receiver positions, the relative angle to an object can be determined in addition to the object distance and speed.

When a large number of transmit and receive combinations are available, the range-angle information can be converted into an image-like three-dimensional representation known as a radar image. In this case, the image reflects the spatial reflectivity or scattering behavior of the observed space and the object.

A major advantage of this method is that electromagnetic waves in the frequency range used penetrate non-conductive media, allowing materials such as plastic, cardboard, glass, etc. to be illuminated.

Due to this property, radar technology represents a sensor principle that is robust to environmental conditions and can be successfully used in dust, smoke, humidity, adverse lighting conditions or reflective surfaces.

Conductive materials, such as metals, on the other hand, cannot be penetrated, which means that conductive objects, but not their contents, can be displayed.

Would you like to learn more about other applications?

Complete the form and one of our solutions and products expert will contact you soon to talk about your individual use case.

Be sure to give us consent for newsletters and other marketing materials so we keep you up to date on the topic of radar imaging. You can also find alternative ways to contact us or to send requests in the "Contact & Support" area.