Entry-level configurator for your RFID system

Without in-depth knowledge of RFID technologies, you can put together your individual solution with Balluff's entry-level configurator. By answering various questions about the application's detection range, the desired frequency, the communication interface and other properties, you are provided with a portfolio tailored to your needs for selection. This makes it easy for you to create an RFID system that is a perfect fit for your requirements. Simply follow the questions listed in the configurator.

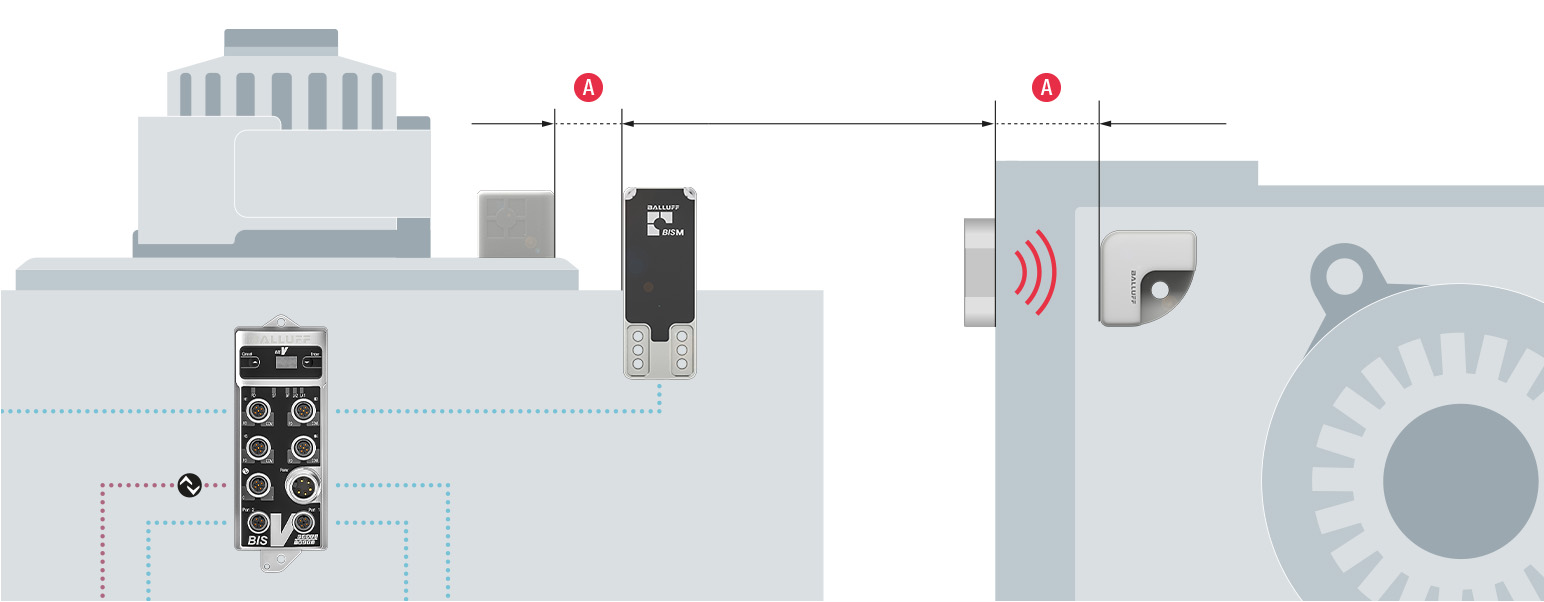

The mounting situation and the metal surfaces in the immediate vicinity play a role in data carrier mounting. To achieve the desired read/write distance, the data carrier must be mounted in a metallic environment at a certain distance from steel (B) and within a defined free zone (A).

The free zone designates the lateral distance at which a data carrier is mounted in a metallic environment in order to achieve a defined read/write distance.

In addition to the free zone, the distance between the data carrier and the steel surface must be taken into account for optimum function.

This refers to the distance between the read/write device and the RFID data carrier.

Min []

Max []

The read distance between the read/write head and the data carrier.

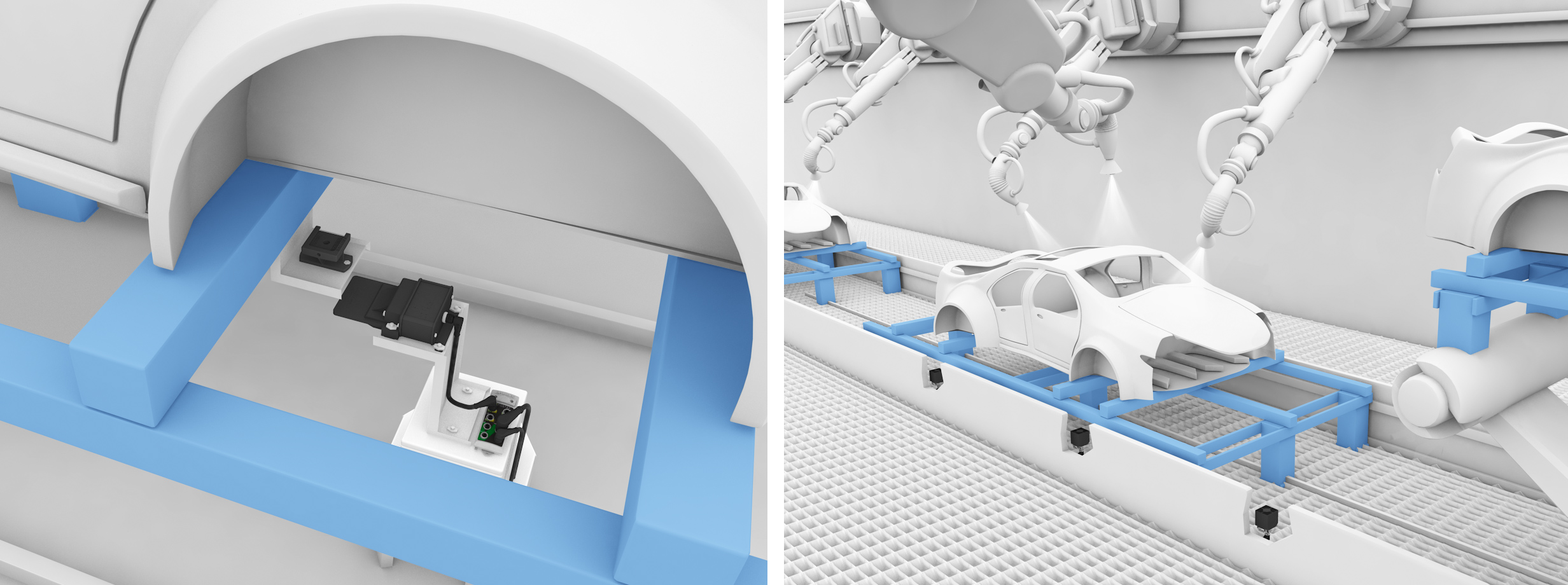

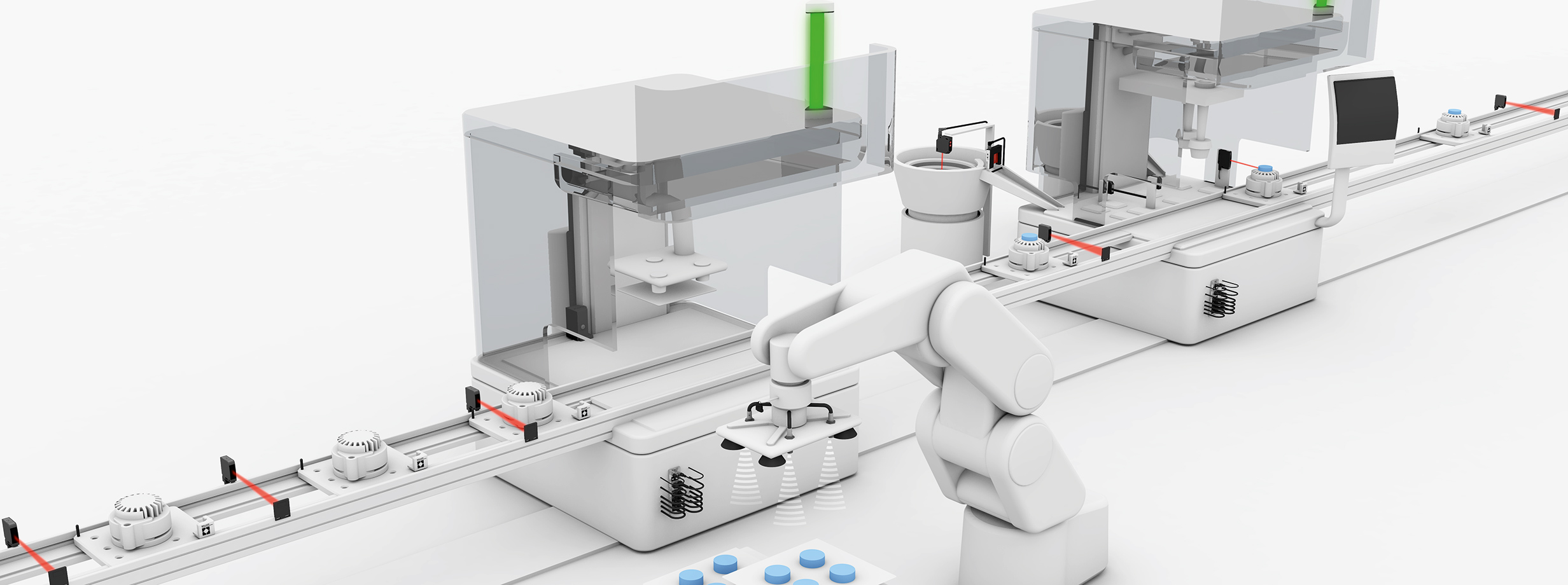

Traceability of production and assembly parts

- Reliable identification in metallic environments

- Data carriers in special designs, such as screws for optimum fastening to the workpiece

- Decentralized data storage directly on the workpiece

Easy Tool ID 2.0

.jpg)

- Retrofit solution for tool identification

- Requirement: USB interface on machine

- No intervention in the machine control system

- Simple and fast commissioning without downtime

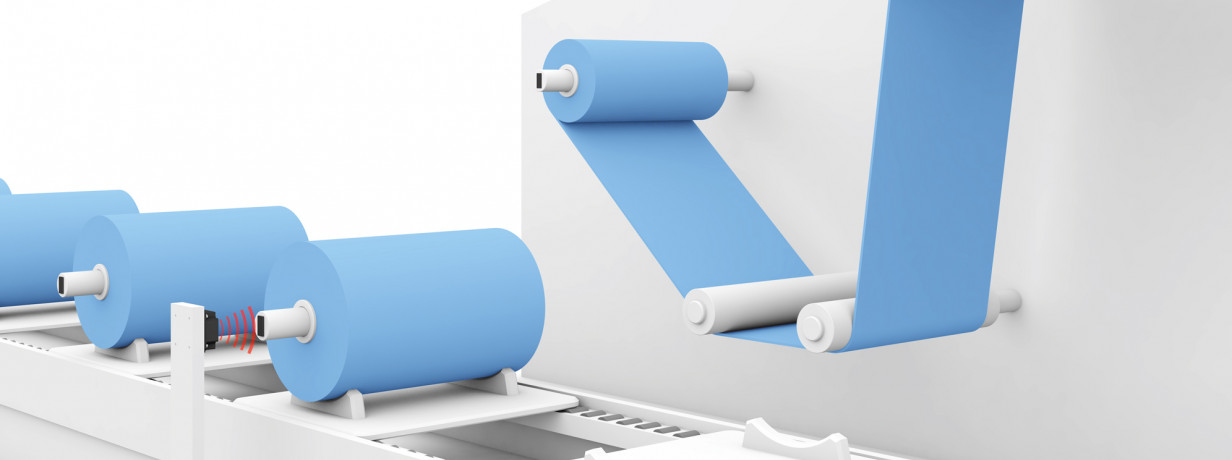

Change part detection

- Robust data carriers in different designs and with different mounting concepts

- read/write heads in different sizes, depending on the required reading ranges and existing space conditions

- small to large read ranges

Plagiarism protection

- Various security mechanisms, e.g. standardized ISO 15693 with write or password protection, as well as ISO 14443 with manufacturer-specific identifier

- Small designs for confined spaces

Conveyor system up to 1m object size

- Different RFID frame antenna designs for different reading ranges

- High-temperature data carriers in various designs and memory sizes

- High performance due to universal evaluation unit BIS V, available for all common bus systems

One-sided UHF reading point with 50cm range

- Ranges of up to 50 centimeters

- Short-Rage-Reader BIS U IO-Link in combination with BNI master module

- Acquisition of multiple data carriers in one process

Access & Access Control

- Data carriers in the form of key fobs, cards or as labels to be affixed to company ID cards

- read/write head with standard/PC interface for easy connection to machine terminals

- various security mechanisms, e.g. standardized ISO 15693 with write or password protection, and ISO 14443 with manufacturer-specific identifier

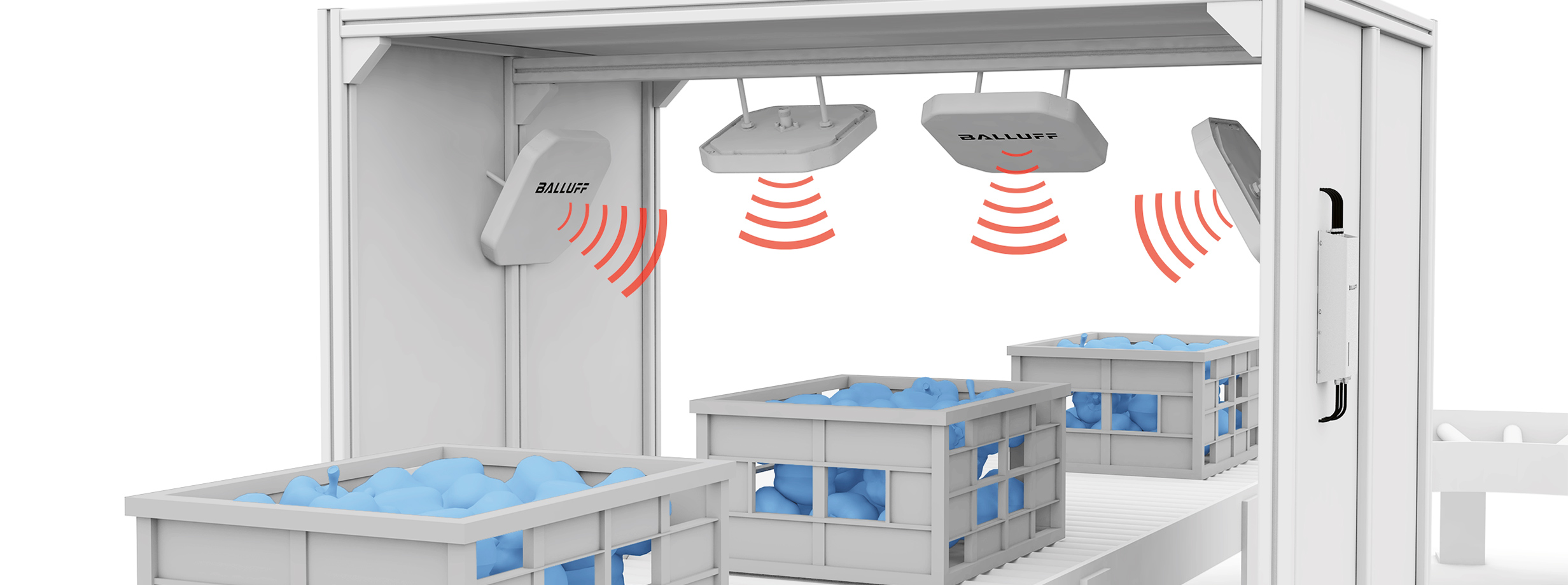

Tunnel application with 1m range

- Ranges of up to 1 meter

- High Performance Evaluation Unit BIS U-61xx for use with up to 4 medium-sized passive antennas

- Acquisition of many data carriers in one process

- Central data storage in the higher-level IT system

Gate application with 2-3m range

- Ranges of 2-3 meters

- High Performance Evaluation Unit BIS U-61xx for use with up to 4 large passive antennas

- Acquisition of many data carriers in one process

- Central data management in the superordinate IT system

Driverless transport vehicle

- Flat, large data carriers for placement on the ground

- Long read range and fast transmission speed for dynamic data transmission on the move

One-sided UHF reading point with 1m range

- Ranges of up to 1 meter

- Short-Rage-Reader BIS VU-320 in combination with multifrequency RFID evaluation unit BIS V

- Acquisition of up to 50 data carriers in one process

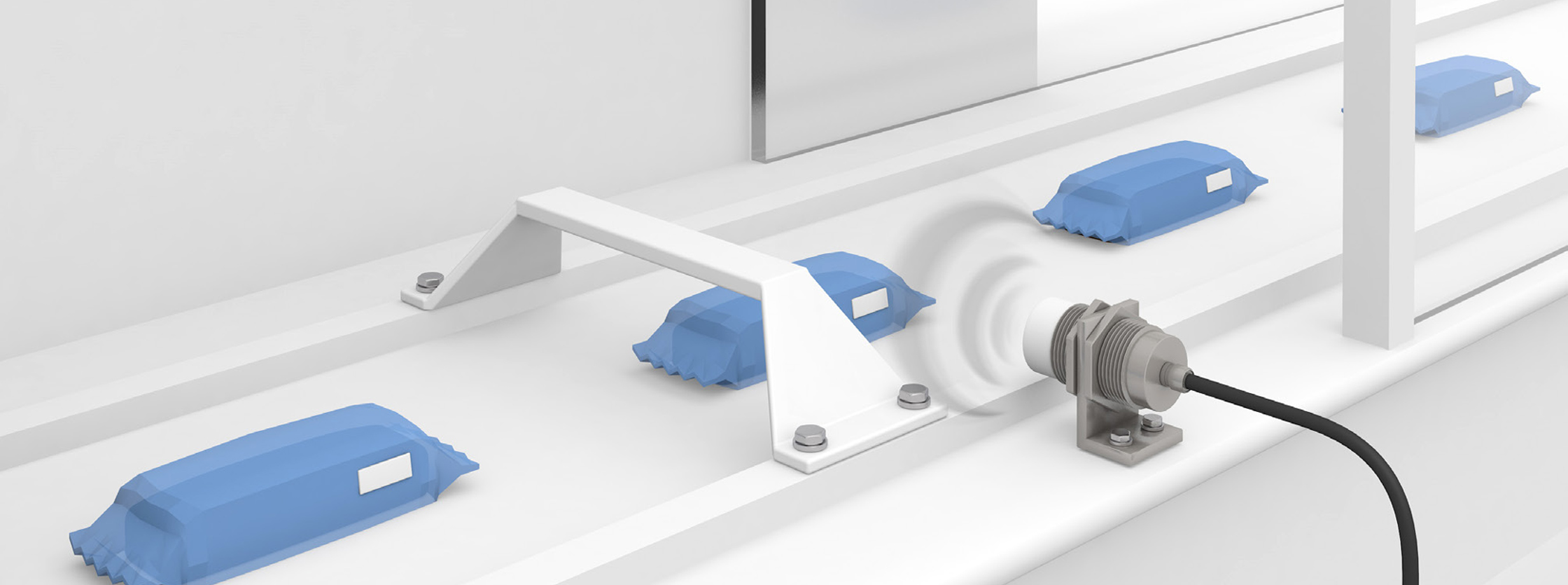

Conveyor system up to 100mm object size

- Data carriers in various designs and sizes for mounting in confined spaces

- Robust and media-resistant data carriers made of glass or PEEK

- Read/write heads in cylindrical and small designs

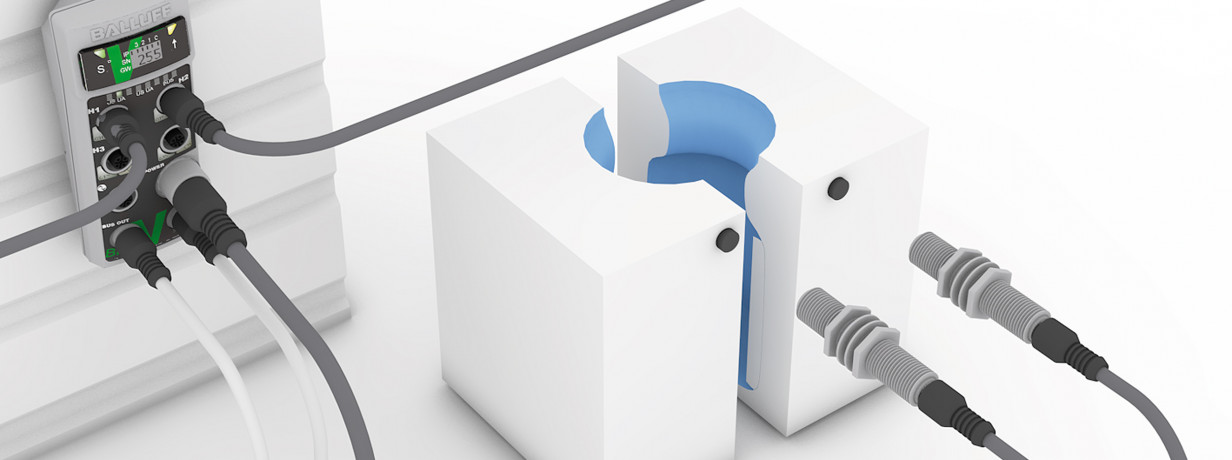

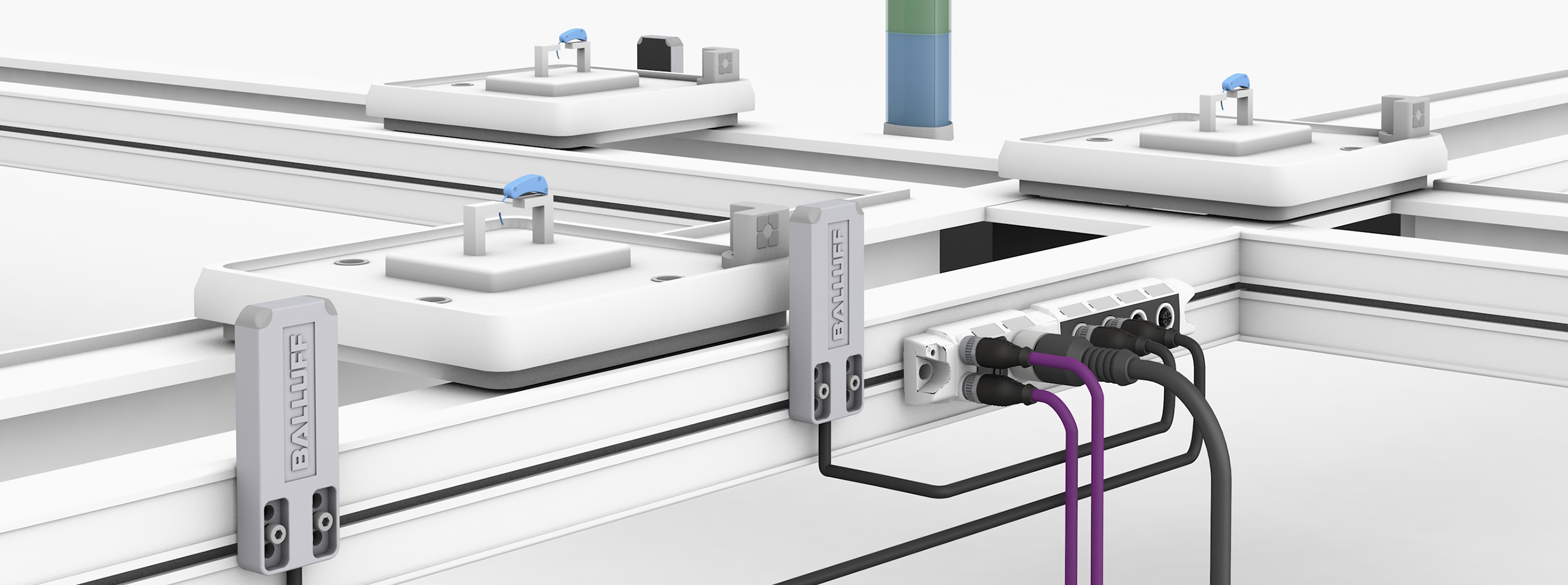

RFID solutions with IO-Link

- Broad portfolio for different reading ranges and environmental conditions

- Extremely economical and flexible in use

- Parameterization and diagnostic options via IO-Link

Different frequencies means different working ranges, because the frequency determines the range. Additionally, the frequency influences the coupling behavior.

In order to be able to help you optimally, please copy the URL from the browser bar for your inquiry and send this link in your inquiry.

Your system

In order to be able to help you optimally, please copy the URL from the browser bar for your inquiry and send this link in your inquiry.

Products

Products