Automation for beginners - Balluff guide

Part 1

Reading Time: minutes

The development of industrial automation is the future of businesses. Automation solutions are used in many areas of manufacturing plants: from the production process, quality control, and logistics. However, before these solutions are put into use it is necessary to learn the basics of automation, without which it would be impossible to understand the functioning of individual devices and systems.

Industry 4.0 brings new challenges and opportunities in the area of automation, and over the next few years this trend will guide the development of the entire industry. To keep up with it, a comprehensive and extensive knowledge of industrial automation is necessary. However, the development does not end with its acquisition.

This knowledge needs to be expanded and updated all the time, as changes and innovations are rapidly taking place before our eyes. Balluff is fully aware that every master was once an apprentice. And it is with beginners in mind that we have created the "Automation Basics" handbook, which contains the most important information on various areas of the field - from sensing, object identification, sensor technology and RFID to IO-Link.

Our study of the basics of industrial automation is aimed primarily at young engineers starting their careers, as well as engineering students and industrial automation enthusiasts. In the first part of the article, we will introduce the audience to the development of issues in the field of detection, object identification and the measurement of various parameters by means of state-of-the-art solutions. We are sure that their variety (text and video formats) will help to assimilate knowledge and best understand the basics of automation.

Automation Basics - Lesson 1: Detection. Sensors see, hear and communicate in their own language

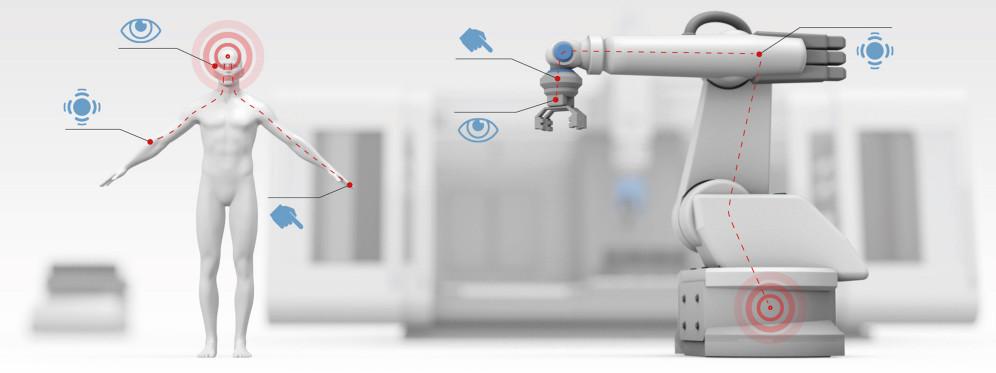

To better understand what industrial automation is all about and how its solutions work, you need to realise that the operation of individual components (sensors, networks, controllers) is comparable to the operation of human senses. Unbelievable? And yet! If we take a closer look, we can see some similarities between humans and machines. This is a somewhat futuristic approach, but it should not be feared - as it serves to better understand how industrial automation solutions work.

For example - the senses of sight, taste, smell or touch correspond to the operation of a number of sensors - optoelectronic, for measuring pressure, vision, capacitive. In turn, the equivalent of the neural net will be the network connections through which data is transmitted - from the control unit to the executive unit. The machine's brain is a PLC logic controller, its ears are ultrasonic sensors and its muscles are various types of motors and drives. Thanks to such a view of machine construction and the basics of industrial automation, even beginners will be able to understand the principles of operation of individual solutions, tailored for Industry 4.0. At first glance, it may seem like a trivial comparison, but it is important to remember that the human body is a machine that is perfect in its operation, which is actually an unsurpassed model for connections, controllers and other elements. Once this analogy becomes clear, however, the rest of the topics in automation for beginners will fit into place.

The topics we introduce in the first chapter of the "tutorial" that connect to the above analogy are:

-

The function, structure and technology of sensors.The discussion includes a description of how sensors work and what components they are made of. In addition, viewers can learn the basic division into inductive sensors, capacitive sensors, optoelectronic sensors, ultrasonic sensors, magnetic field sensors or linear transducers. We do not provide "dry" facts - we present each type of sensor with examples of products that are available from Balluff.

-

The second topic is everything related to sensor electronics.We discuss types of outputs (PNP, NPN) and contacts (NO/NC). We suggest how to choose a specific solution for defined needs and explain in detail the differences between them - and we supplement all this with simple schematic drawings.

-

The third topic concerns the differences between switching and measuring sensors.We discuss the important issues of the types of signals at the output and show examples of practical applications.

-

The next topic deals with issues of resolution, linearity deviation and accuracy in industrial automation.These are the most important features of a measurement sensor, without which it would be impossible to understand the essence of its functioning.

-

The last topic is a discussion of how to power sensors, that is, providing detailed information about where the sensor gets its voltage from. We show how voltage processing takes place, and also present products from Balluff's portfolio that fit into this topic.

Automation Basics - Lesson 2: Object Detection and Identification.

Detection is another extremely important topic we look at in Automation Basics. Sensors are used in manufacturing plants and companies in many different applications: during the production process, quality control or finished product packaging and logistics.

Sensing is primarily based on the identification of objects, as well as their positioning. Using appropriate sensors, not only solids (metallic and non-metallic), but also liquids can be detected. Various technologies are used to identify objects, such as magnetic field detection, as well as solutions based on the properties of light and sound, which are encapsulated in devices representative of industrial automation - that is, sensors.

The aforementioned devices can be classified according to a simple division: Inductive sensors (which are used to detect all metallic objects that are at a distance of a few or a few tens of mm), capacitive sensors (detect everything that has a certain capacitance at close range), optoelectronic sensors (they are divided into diffuse which use the object to reflect light back to the sensor, and retro-reflective optoelectronic sensors which operate on the principle of a unidirectional barrier - with their help the detection of objects is possible at greater distances) and ultrasonic sensors (used to detect almost all objects at greater distances).

In order to make it easier for the audience to assimilate the basics of industrial automation and the subject of sensors and object identification, Balluff has proposed the following division of topics:

-

Recognition, detection and positioning of metallic objects using sensors.In this issue, we discuss sensor technologies (inductive, capacitive, optoelectronic, ultrasonic) that can be used to identify metal objects. We also point out examples of applications of the aforementioned devices and present products from Balluff's portfolio that correspond to the issue at hand.

-

Recognising, detecting and positioning non-metallic objects using sensors.A capacitive, optoelectronic or ultrasonic sensor can be used for this type of operation, and we point out that not every type of sensor is suitable for detecting non-metallic objects. We present practical application examples and products that fit into the above issue.

-

Detection of the piston rod in a pneumatic cylinder using magnetic field sensors.As part of this issue, we discuss the conditions and requirements that must be met for the sensor to work effectively, and present practical applications.

-

Determining the level of liquids and solids with sensors.In this section, we discuss capacitive and ultrasonic sensor technologies that are ideal for measuring the level of liquids and other substances. We show practical applications and suggest what ultrasonic or capacitive sensor parameters to pay attention to in order for the device to work flawlessly.

Fundamentals of automation - lesson 3: Measurement of position, distance, pressure

Precise measurements of parameters (position, distance, pressure) affect many aspects in a company - in particular, production and the possibility of optimising it. It is important that measurements are made in real time, with the greatest possible precision.

Thanks to industrial automation solutions, it is possible to measure in detail the position of objects, distances, angles or pressure - with appropriately selected devices. For each parameter - pressure, distance, angles or position - the methods of measurement are different, so before selecting a specific solution, it is necessary to carefully define the needs to which it is to respond.

Various solutions are used to make measurements of position and other parameters - one example is the linear transducer, which allows measurement of several positions at the same time - even under harsh operating conditions.

The second type is magnetic encoding technology (which magnetic encoders use) - best suited for precise measurements made in real time.

The third and fourth types (represented by sensors), are inductive technology (suitable for measurements at close distances) and optoelectronic technology (makes measurements regardless of distance, object texture and color). What issues in this topic will be discussed in detail?

-

Distance measurementwhich is one of the most common challenges faced by industrial automation solutions. An inductive, capacitive or ultrasonic sensor, as well as an optoelectronic sensor, can be used to perform it. In this section we also discuss practical application examples - for example, supervision, monitoring of brake operation in wind turbines.

-

Linear position measurement, or positioning of objects in a straight line - we discuss sensor technologies for this purpose - examples include such elements as magnetic encoder, inductive position measurement systems and linear transducers. We suggest which technology will work best for specific applications (e.g., for incorporation into a linear or hydraulic drive).

-

Rotary position measurementwhose applications we give the example of a printing and cutting machine. For this type of measurement, a magnetic encoder or inclinometer works well, the technical parameters of which allow to achieve a result with high precision.

-

Controlling the states of liquids, gases and solids- we discuss sensor technologies that are suitable for this type of measurement (ultrasonic sensor, capacitive sensor or linear sensor) and how to install them (which directly affects their correct operation). We also cite possible applications in tanks or boilers.

Industrial automation is a very broad field - explaining its basics, however, gives us a lot of satisfaction - especially when we receive positive feedback from our audience. In the next article in our "Automation Basics" series, we will discuss sections on RFID technology, network connections and the IO-Link interface.

Keywords

- Industrial Automation

- Basics of Automation

Author

Balluff Sp. z o.o.

We have been active on the Polish market for more than 25 years. We serve our customers from Pomerania to the Tatra Mountains, providing first-class service and technical support. We are also present online, where we share our knowledge about the latest implementations, industry trends, events or technical aspects of our solutions.

7 Contributions

Comment

Popular posts

An easy way to remember PNP and NPN sensor wiring

Real-time speed of IO-Link wired

Advantages of inductive proximity sensors in industry

Automation for intralogistics: a practical perspective

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff GmbH

-

Zabergäustraße 8

73765 Neuhausen a.d.F.